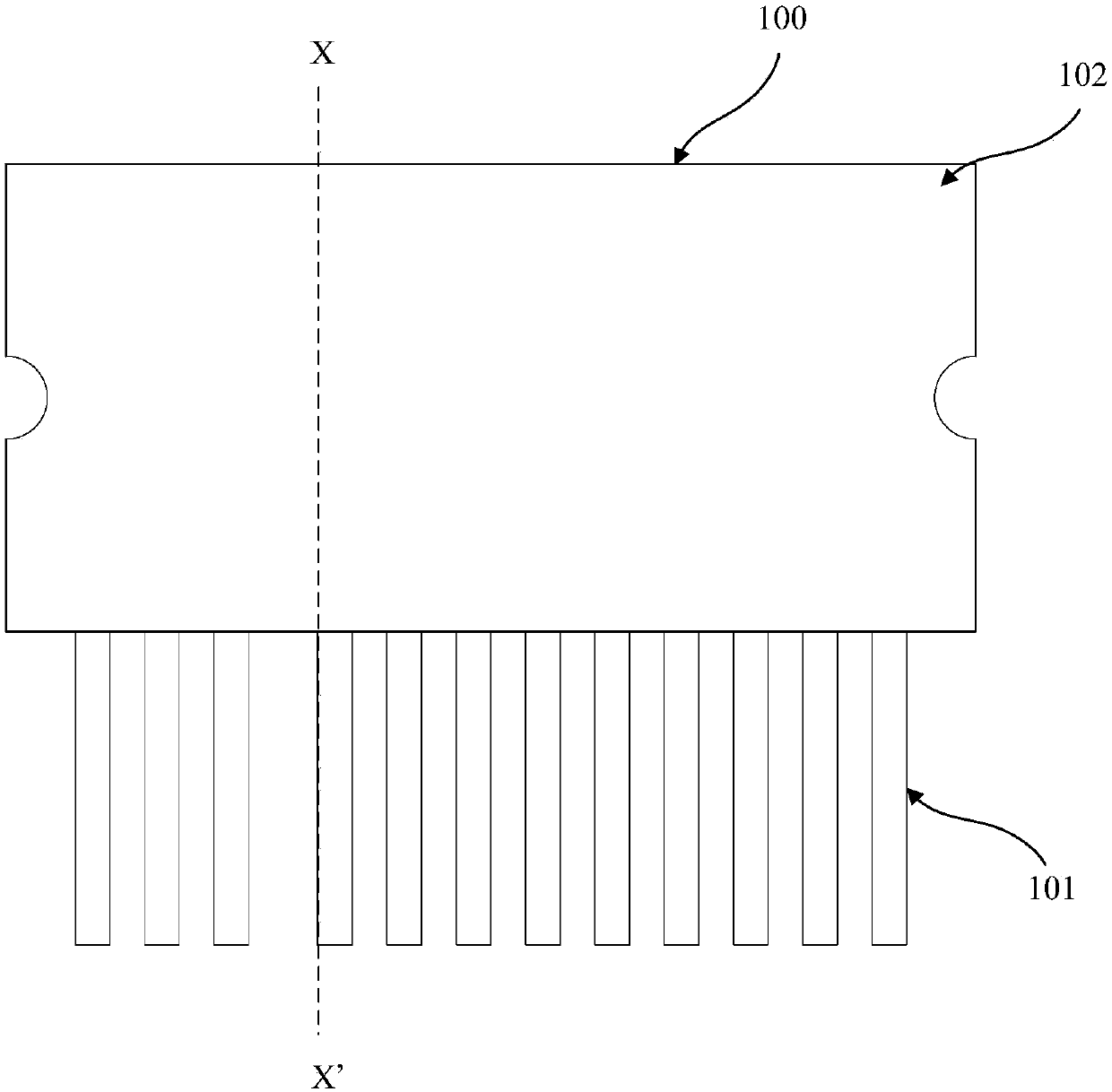

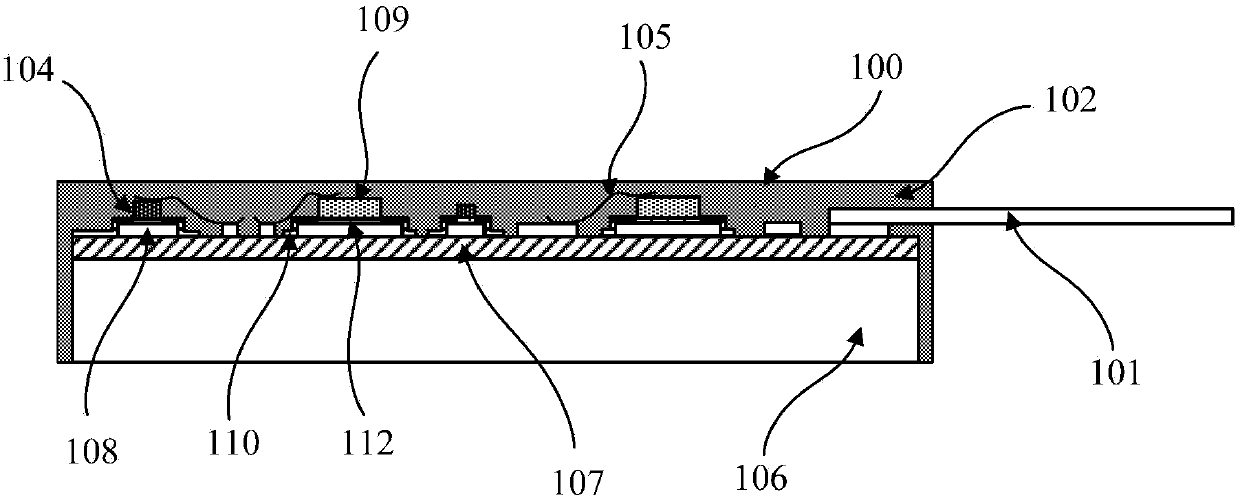

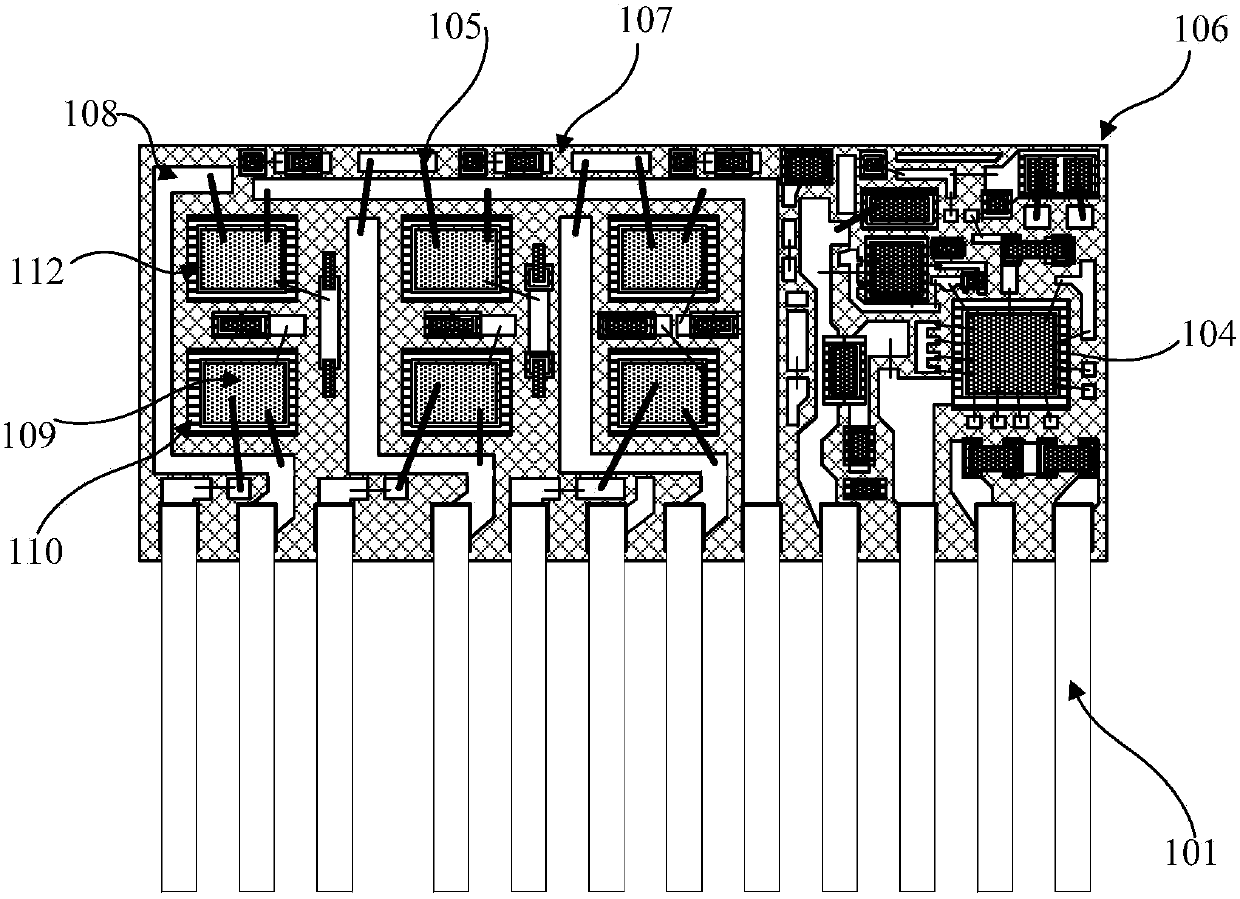

Intelligent power module and manufacturing method thereof

A technology of an intelligent power module and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, electric solid-state devices, etc., can solve the problems of high thermal resistance of the intelligent power module 100, uncontrolled explosion of the intelligent power module, affecting performance stability, etc. , to achieve the effect of reducing thermal crosstalk, low carrier requirements, and easy positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0071] As mentioned above, due to the poor heat dissipation effect of the existing intelligent power modules, working at high temperature for a long time will seriously reduce their service life and affect the stability of the intelligent module performance.

[0072] The present invention considers that in specific applications such as frequency conversion air conditioners, although the high thermal conductivity insulating layer and the addition of radiators can solve the heat dissipation problem of the intelligent power module, the cost of using the high thermal conductivity insulating layer for heat dissipation is very high on the one hand, and on the other hand Due to the use of a large amount of doping in the high thermal conductivity insulating layer, the smart power module is very hard, which increases the diffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com