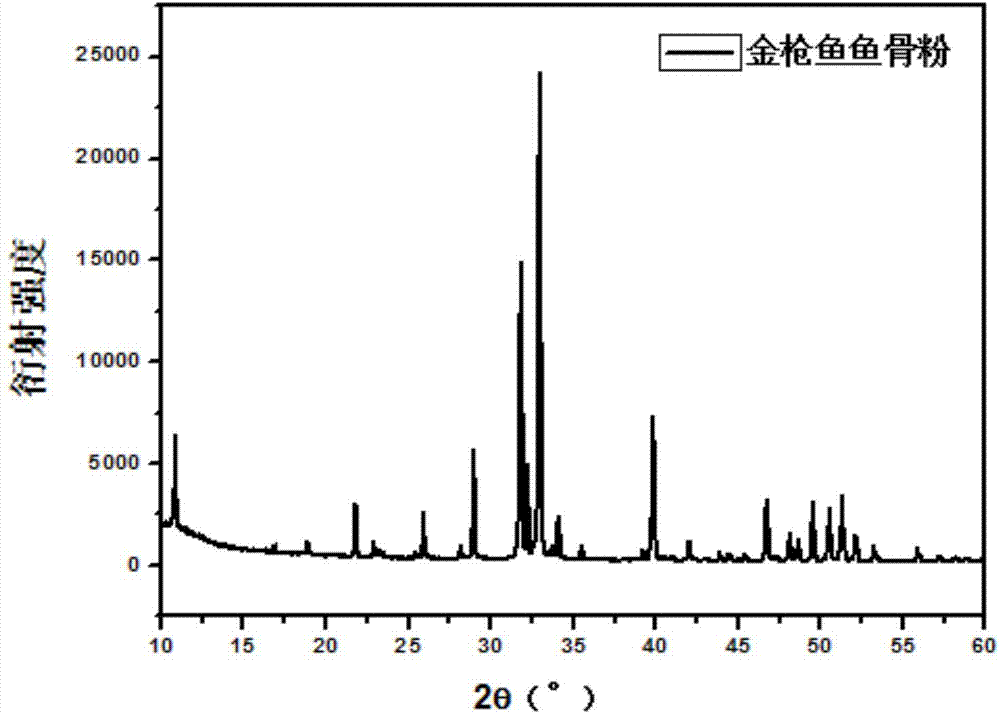

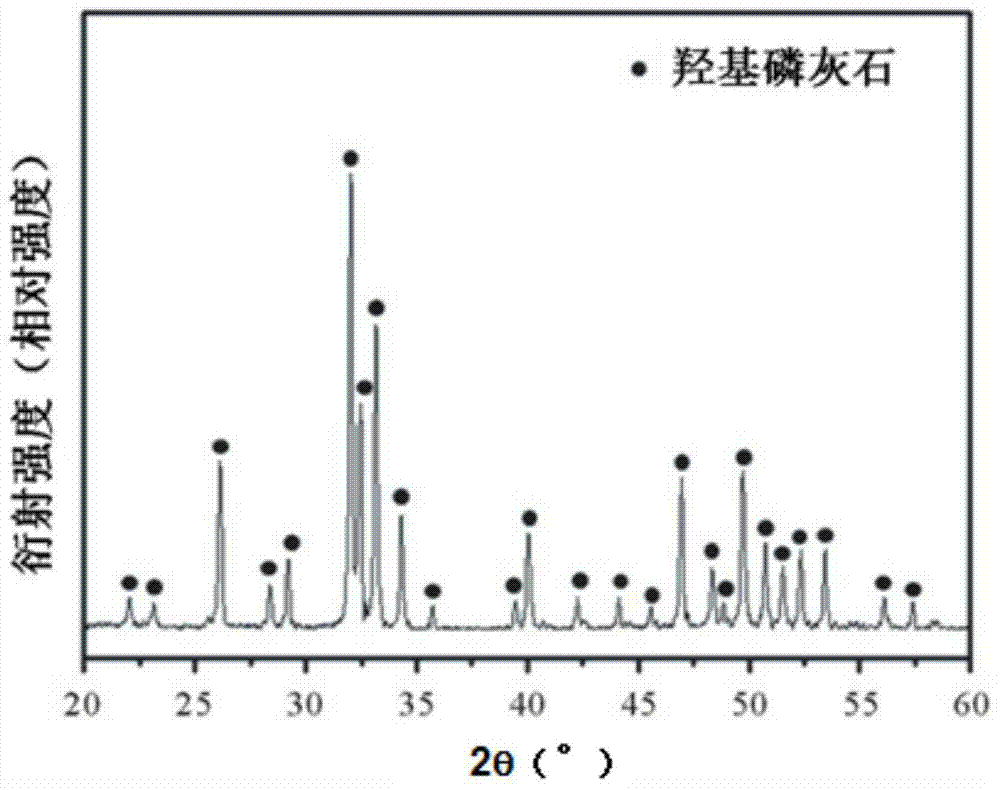

Tuna fishbone meal material, preparation method and application thereof

A technology of fish bone meal and tuna, which is applied in the field of medical and sanitary materials, can solve the problems of high cost of bone meal, weak bone capacity, and great difficulty, and achieve the effects of controllable product quality, promoting bone growth, and reducing heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

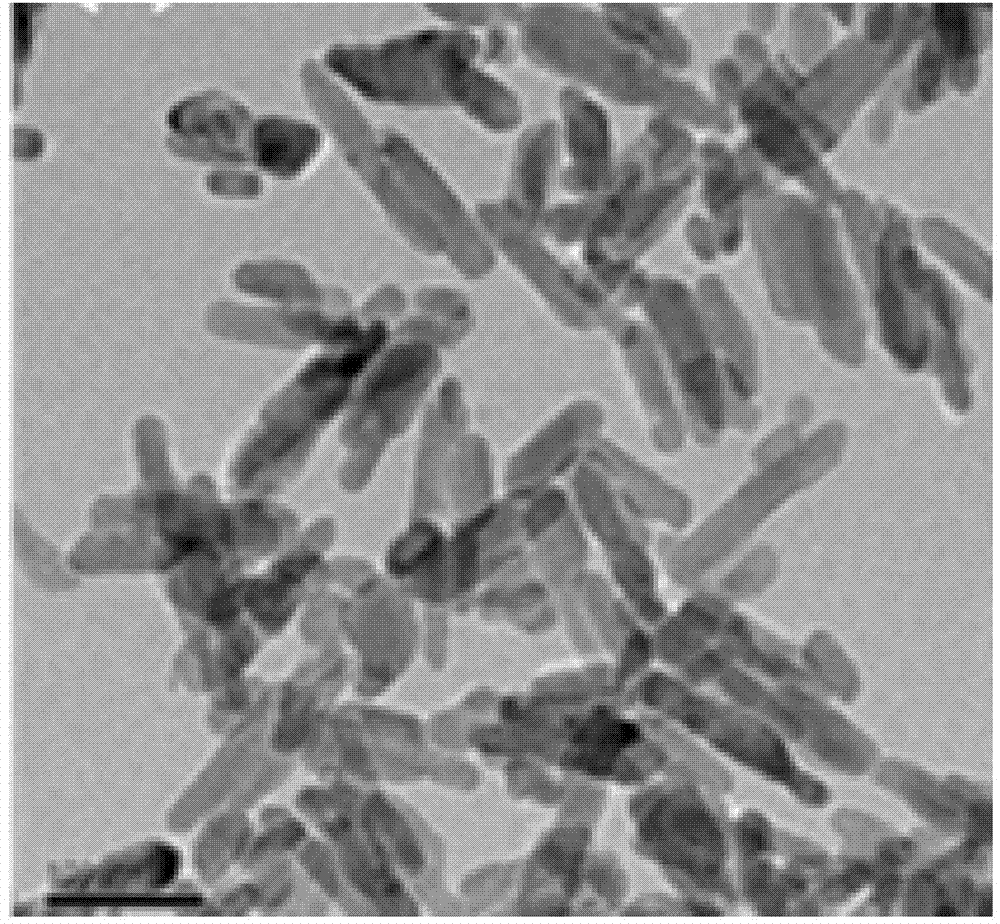

Examples

Embodiment 1

[0043] The present embodiment provides a kind of tuna fish bone meal material, and it adopts following method to prepare:

[0044] (1) Select 2Kg of tuna fish bones that have been removed from most of the meat quality. After cleaning, use a bone and meat separator and a rolling mill to further remove meat and initially crush them. The preliminary broken tuna fish bones are expected to have a particle size of 5-20mm. ;Put the fish bones into the cooking pot for high-temperature and high-pressure cooking at a temperature of 100°C and a pressure of about 1.1 bar, and cook for about 2 hours to obtain the initial fish bones; the purpose of cooking is to initially remove a small amount of residual fish meat and lipids on the surface of the bone ; Then, filter and clean the fish bone primary material.

[0045] (2) Put the fishbone initial material after cleaning in the previous step into a molar concentration of 5% sodium bisulfite buffer and soak for about 3 hours to remove the heav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com