Applying porous organic polymer to epoxidation of olefin on basis of Salen-Mn

A polymer and organic technology, applied in the application field of catalytic olefin epoxidation reaction, can solve the problems of large carrier, poor cycle performance, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

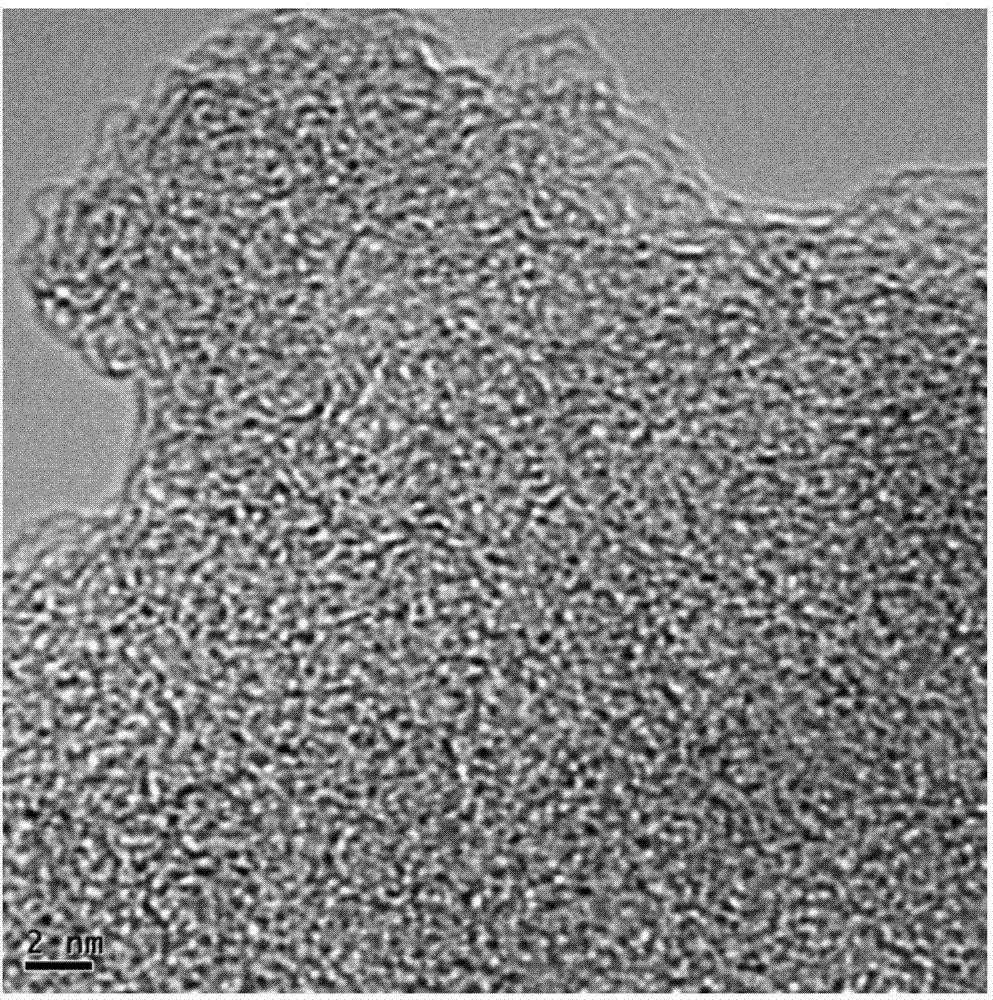

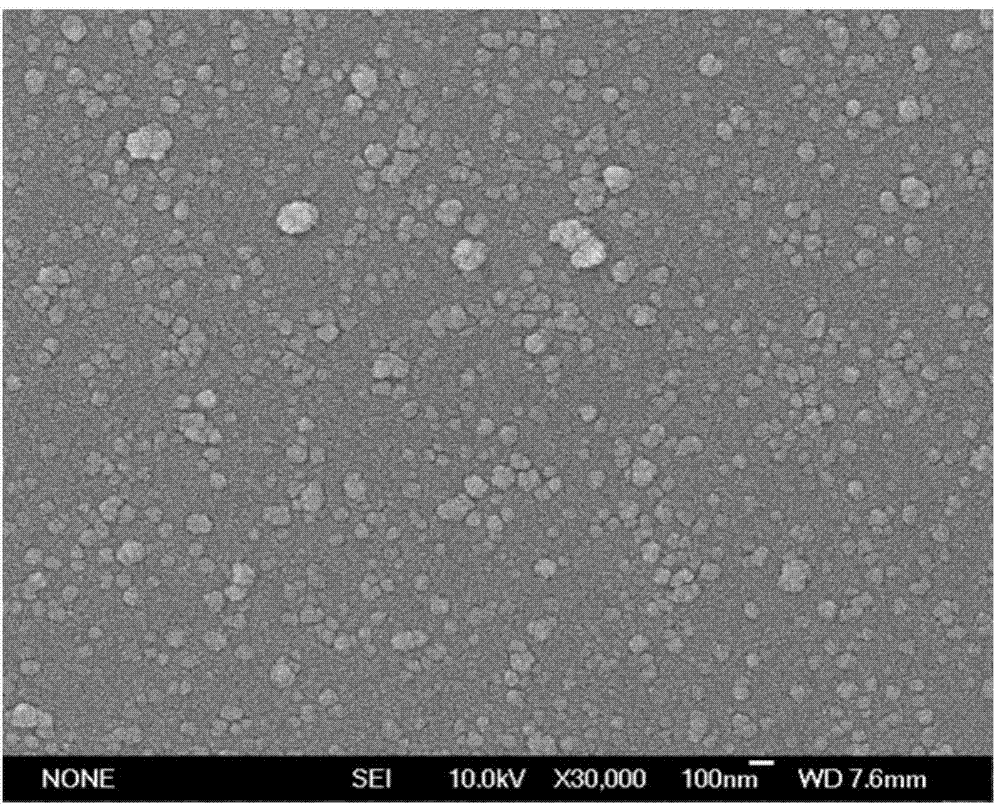

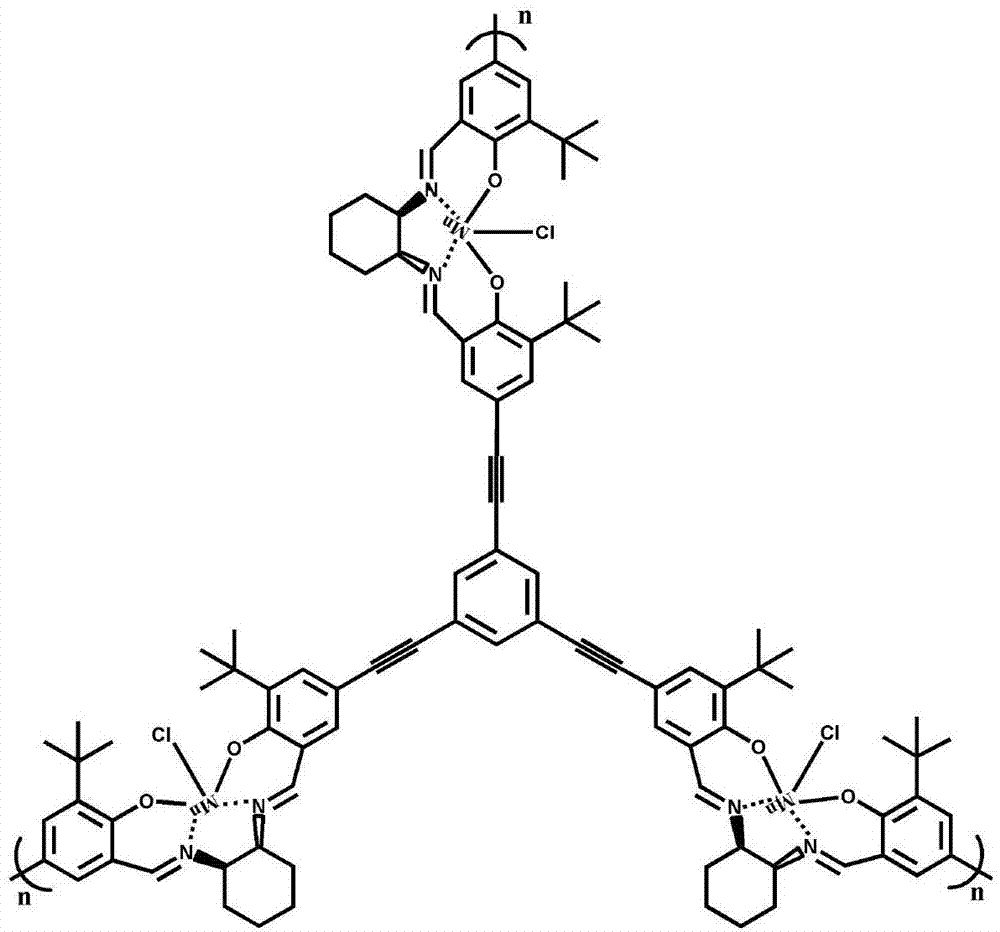

[0010] Embodiment 1: Mn-POP catalyst

[0011] Add Salen-Mn ligand and s-triynylbenzene into a three-necked flask equipped with a serpentine condenser, and use dry N,N-dimethylformamide as a solvent and dry triethylamine in a nitrogen atmosphere throughout the reaction. As the acid-binding agent, Pd(PPh 3 ) 2 Cl 2 As the main catalyst, CuI was used as the sub-catalyst, and the reaction was refluxed at 90°C for 24 hours. After the reaction is completed, centrifuge, dry in a vacuum oven, extract methanol for 24 hours, and dry in a vacuum oven to obtain the heterogeneous catalyst Mn-POP.

Embodiment 2

[0012] Embodiment 2: Mn-POP catalyst catalyzes olefin epoxidation reaction

[0013] Add cyclohexene, isobutyraldehyde, catalyst Mn-POP respectively in reaction system, the ratio of the amount of substance of the three (wherein Mn-POP takes the content of the metal in the polymer as the amount of substance calculation standard) ratio is 1: 7: 0.001, 1,2-dichloroethane is used as a solvent, the reaction is equipped with a high-efficiency condenser, oxygen is passed into the reaction system in the form of bubbling, the speed is 16ml / min, the reaction temperature is 25°C, after 10 hours of reaction, centrifuge, catalyst Wash with 1,2-dichloroethane, place at room temperature for half an hour, and recycle; the liquid phase part is dried with anhydrous sodium sulfate, and separated by column chromatography to obtain the corresponding olefin epoxidation reaction product.

Embodiment 3

[0014] Embodiment 3: Mn-POP catalyst catalyzes olefin epoxidation reaction

[0015] In reaction system, add cyclooctene, isobutyraldehyde, catalyst Mn-POP respectively, the ratio of the amount of substance of the three (wherein Mn-POP takes the content of the metal in the polymer as the amount of substance calculation standard) ratio is 1: 7: 0.001, 1,2-dichloroethane is used as a solvent, the reaction is equipped with a high-efficiency condenser, oxygen is passed into the reaction system in the form of bubbling, the speed is 16ml / min, the reaction temperature is 25°C, after 10 hours of reaction, centrifuge, catalyst Wash with 1,2-dichloroethane, place at room temperature for half an hour, and recycle; the liquid phase part is dried with anhydrous sodium sulfate, and separated by column chromatography to obtain the corresponding olefin epoxidation reaction product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com