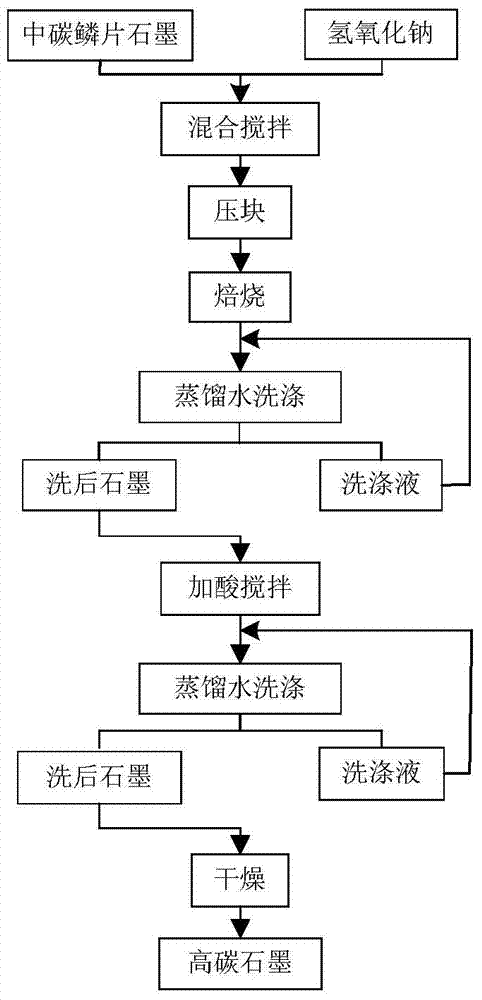

Method for preparing high-carbon graphite by using middle-carbon crystalline flake graphite as raw material

A medium-carbon flake and graphite technology, applied in the field of high-carbon graphite preparation, can solve problems such as high production costs, and achieve the effects of improving utilization, reducing corrosion, and lowering reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Material preparation: medium carbon flake graphite: the fixed carbon content is 95wt.%, and the particle size is 100 orders; Sodium hydroxide: the solid form is powder; Hydrochloric acid: the mass concentration is 4%, and the mass ratio of the three is 3 :10:170.

[0023] (2) After mixing and stirring the medium carbon flake graphite and sodium hydroxide, place it in a powder tablet press, press it into a block under a pressure of 20MPa, and maintain the pressure for 9min to obtain a density of 1.9g / cm 3 graphite prefabricated blocks.

[0024] (3) Embed the prefabricated graphite block in powdery medium carbon flake graphite, and place it in a box-type resistance furnace, maintain it at 500°C for 3 hours, then dissolve the graphite block that has been taken out and cleaned the surface into water, stir and filter, repeat Wash until the pH of the filtrate = 7.0, and collect the powder for later use.

[0025] (4) Dissolve the graphite powder obtained in step (3) in h...

Embodiment 2

[0028] (1) Material preparation: medium carbon flake graphite: the fixed carbon content is 95wt.%, and the particle size is 100 orders; Sodium hydroxide: the solid form is powder; Hydrochloric acid: the mass concentration is 9%, and the mass ratio of the three is 2 :10:60.

[0029] (2) After mixing and stirring the medium carbon flake graphite and sodium hydroxide, place it in a powder tablet press, press it into a block under a pressure of 30MPa, and maintain the pressure for 10min to obtain a density of 2.0g / cm 3 graphite prefabricated blocks.

[0030] (3) Embed the prefabricated graphite block in powdery medium carbon flake graphite, and place it in a box-type resistance furnace, maintain it at 450°C for 3 hours, then dissolve the graphite block that has been taken out and cleaned the surface into water, stir and filter, repeat Wash until the pH of the filtrate = 7.0, and collect the powder for later use.

[0031] (4) Dissolve the graphite powder obtained in step (3) in h...

Embodiment 3

[0034] (1) Material preparation: medium carbon flake graphite: the fixed carbon content is 88wt.%, and the particle size is 32 orders; Sodium hydroxide: solid form is powder; Hydrochloric acid: mass concentration is 15%, and the mass ratio of the three is 2 :10:60.

[0035] (2) After mixing and stirring the medium carbon flake graphite and sodium hydroxide, place it in a powder tablet press, press it into a block under a pressure of 30MPa, and maintain the pressure for 10min to obtain a density of 2.0g / cm 3 graphite prefabricated blocks.

[0036] (3) Embed the prefabricated graphite block in powdery medium carbon flake graphite, and place it in a box-type resistance furnace, maintain it at 450°C for 3 hours, then dissolve the graphite block that has been taken out and cleaned the surface into water, stir and filter, repeat Wash until the pH of the filtrate = 7.0, and collect the powder for later use.

[0037] (4) Dissolve the graphite powder obtained in step (3) in hydrochlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com