Method used for applying bromine extraction bittern to sodium carbonate production

A technology of brine and soda ash, which is applied in the direction of chemical instruments and methods, alkali metal chlorides, alkali metal compounds, etc., can solve problems such as unrealized, and achieve the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In this example, the various components and indicators in the bromine extraction brine: the pH value is 2.6, the oxide content is 0.95ppm, the calcium ion content is 1006 mg / L, the magnesium ion content is 7749 mg / L, and the sulfate content is 11087 mg / L. L, sodium chloride content 89.8g / L, suspended matter content 23mg / L.

[0032] After the bromine-extracting brine was dried in the solar decomposition tank for 3 days, the pH value increased to 3.1, and the oxide content dropped to 0.80 ppm. After adding 1.1 ppm sodium sulfite, the pH value of the bromine-extracting brine increased to 5.5, and the oxide content was zero. Send this bromine-extracting brine into a sand filter device filled with anthracite, activated carbon and quartz sand, and then into an ultrafiltration device whose membrane material is PVDF. ppm.

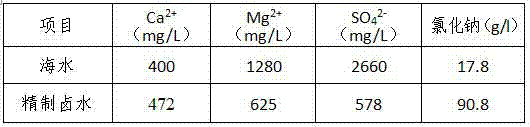

[0033] Add 5ppm antiscalant (sodium hydroxyethyl diphosphonate, polyepoxysuccinic acid, phosphonic acid butane-1,2,4 tricarboxylic acid according to the mo...

Embodiment 2

[0037] In this embodiment, the various components and indicators in the bromine-extracting brine: the pH value is 2.8, the oxide content is 1.15ppm, the calcium ion content is 1408 mg / L, the magnesium ion content is 6163 mg / L, and the sulfate content is 11087 mg / L , sodium chloride content 91.5g / L, suspended matter content 18mg / L.

[0038] After the bromine-extracting brine was dried in the solar decomposition tank for 8 days, the pH value increased to 3.3, and the oxide content dropped to 0.51ppm. After adding 0.8ppm sodium sulfite, the pH value of the bromine-extracting brine increased to 5.8, and the oxide content was zero. Send this bromine-extracting brine into a sand filter device filled with modified fiber balls and pebbles, and then into an ultrafiltration device with PS membrane material. The osmotic pressure of the ultrafiltration is 0.36MPa, and the suspended matter content in the filtrate is reduced to 0.11 ppm.

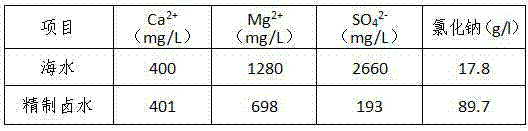

[0039] Add 8ppm antiscalant (polymaleic acid-acryl...

Embodiment 3

[0043] In this embodiment, the various components and indicators in the bromine-extracting brine: the pH value is 2.0, the oxide content is 1.2ppm, the calcium ion content is 952 mg / L, the magnesium ion content is 5684 mg / L, and the sulfate content is 9749 mg / L. L, sodium chloride content 90.2g / L, suspended matter content 10mg / L.

[0044] After the bromine-extracting brine was dried in the solar decomposition tank for 4 days, the pH value increased to 3.1, and the oxide content dropped to 0.77ppm. After adding 1.05ppm sodium sulfite solution, the pH value of the bromine-extracting brine increased to 5.6, and the oxide content was zero. The bromine-extracting brine is sent to a sand filter device filled with emery and fiber balls, and then sent to an ultrafiltration device whose membrane material is stainless steel. The osmotic pressure of the ultrafiltration is 0.5 MPa, and the suspended matter content in the filtrate is reduced to 0.16 ppm.

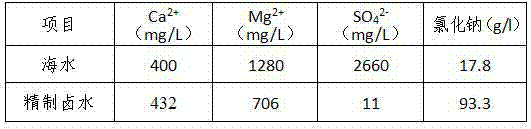

[0045] Add 5ppm antiscalant (hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com