Novel amphiphilic block acrylic resin retanning agent and preparation method thereof

An acrylic resin, amphiphilic block technology, applied in animal husbandry, chemical treatment of small raw hides/large raw hides/leather hides/furs, applications, etc., to achieve the effect of excellent acid resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

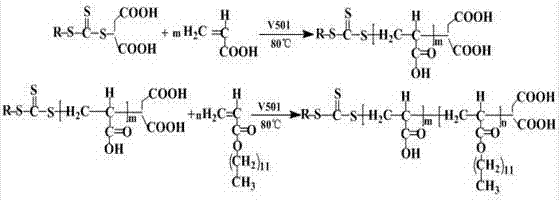

[0016] 1. Reversible addition-fragmentation chain transfer radical polymerization of acrylic acid: 90 parts of acrylic acid, 4.5 parts of RAFT reagent, 0.9 part of 4,4'-azobis(4-cyanovaleric acid) (V501), 0.5 part of carbonic acid Add sodium hydrogen, 256.7 parts of deionized water and 5 parts of mixed emulsifier into the reaction kettle, heat up to 80°C, and react for 3 hours to obtain polyacrylic acid macromolecule RAFT reagent; 2. Synthesis of amphiphilic block acrylic resin retanning agent: Continue to add 0.45 parts of 4,4'-azobis(4-cyanovaleric acid) (V501) to the reactor, add 10 parts of lauryl acrylate dropwise into the reactor within 2 hours, and continue the reaction after the addition is complete After 4 hours, after the reaction was completed, an amphiphilic block acrylic resin retanning agent was obtained.

Embodiment 2

[0018] 1. Reversible addition-fragmentation chain transfer radical polymerization of acrylic acid: 90 parts of acrylic acid, 4.5 parts of RAFT reagent, 0.9 part of 4,4'-azobis(4-cyanovaleric acid) (V501), 0.5 part of carbonic acid Add sodium hydrogen, 256.7 parts of deionized water and 5 parts of mixed emulsifier into the reaction kettle, heat up to 80°C, and react for 3 hours to obtain polyacrylic acid macromolecule RAFT reagent; 2. Synthesis of amphiphilic block acrylic resin retanning agent: Continue to add 0.45 parts of 4,4'-azobis(4-cyanovaleric acid) (V501) to the reactor, and add 10 parts of lauryl methacrylate dropwise into the reactor within 2 hours. The reaction was continued for 4 hours, and after the reaction was completed, an amphiphilic block acrylic resin retanning agent was obtained.

Embodiment 3

[0020] 1. Reversible addition-fragmentation chain transfer radical polymerization of methacrylic acid: 80 parts of methacrylic acid, 4 parts of RAFT reagent, 0.8 part of 4,4'-azobis(4-cyanovaleric acid) (V501) , 0.5 parts of sodium bicarbonate, 255.5 parts of deionized water and 5 parts of mixed emulsifier were added to the reaction kettle, the temperature was raised to 80°C, and the reaction was carried out for 3 hours to obtain a polymethacrylic acid macromolecule RAFT reagent; 2. Amphiphilic block acrylic resin Synthesis of retanning agent: continue to add 0.4 parts of 4,4'-azobis(4-cyanovaleric acid) (V501) to the reaction kettle, and drop 20 parts of lauryl acrylate into the reaction kettle dropwise within 2 hours After the addition, the reaction was continued for 4 hours. After the reaction was completed, an amphiphilic block acrylic resin retanning agent was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com