Method for extracting oat beta-glucan through fermentation method

A technology of glucan and fermentation, which is applied in the field of extracting oat β-glucan, can solve the problems of low extraction rate and high cost, and achieve the effect of simple steps, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1. Extraction of oat β-glucan by fermentation of Aspergillus niger

[0021] The specific implementation steps are as follows:

[0022] 1) After the oat grains are ground, pass through a 50-mesh sieve, take the oat bran on the sieve, add 82% ethanol at a solid-to-liquid mass volume ratio of 1:5, reflux in a water bath at 85 °C for 2 h, and centrifuge at 1000 r / min for 5 min to remove ethanol Retain the precipitate, and dry it in a blast oven at 40°C for 12 h to obtain oat bran;

[0023] 2) Prepare 5×10 6 Individual / mL Aspergillus niger spore suspension, 4 ° C preservation;

[0024] 3) Weigh 5 g of oat bran and sterilize it by autoclaving, add sterile water at a solid-to-liquid ratio of 1:10 (W / V), and inoculate the Aspergillus niger spore suspension for fermentation. Fermentation conditions: fermentation time 10.30 h, inoculum volume 12 mL, fermentation temperature 42 °C, rotation speed 180 r / min;

[0025] 4) Collect the fermentation product and extract it wi...

Embodiment 2

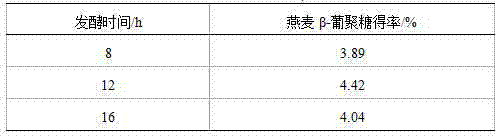

[0031] Example 2, the influence of fermentation time on the extraction of oat β-glucan by Aspergillus niger fermentation method

[0032] In order to compare the effect of fermentation time on the yield of oat β-glucan, the fermentation time of step 3) in Example 1 was changed to 8, 12, and 16 h, and the rest of the steps were the same as Example 1.

[0033] The yield of oat β-glucan under different fermentation times is shown in Table 1:

[0034] Table 1 Yield of oat β-glucan under different fermentation times

[0035]

Embodiment 3

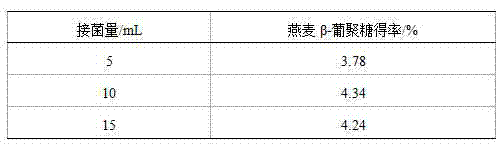

[0036] Example 3, the effect of inoculation amount on the extraction of oat β-glucan by Aspergillus niger fermentation method

[0037] In order to compare the effect of the inoculation amount on the yield of oat β-glucan, the inoculation amount in step 3) in Example 1 was changed to 5, 10, and 15 mL, and the rest of the steps were the same as in Example 1.

[0038] The yield of oat β-glucan under different inoculation amount is shown in Table 2:

[0039] Table 2 Yield of oat β-glucan under different inoculation amount

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com