Laser thermal treatment process for skid shoe of coal cutter

A technology of laser heat treatment and coal mining machine, which is applied in the field of heat treatment, can solve the problems of increasing the use and maintenance cost of coal mining machine, short service life of sliding shoes, and affecting the efficiency of coal mining, so as to reduce the number of replacements, save time, The effect of ensuring production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

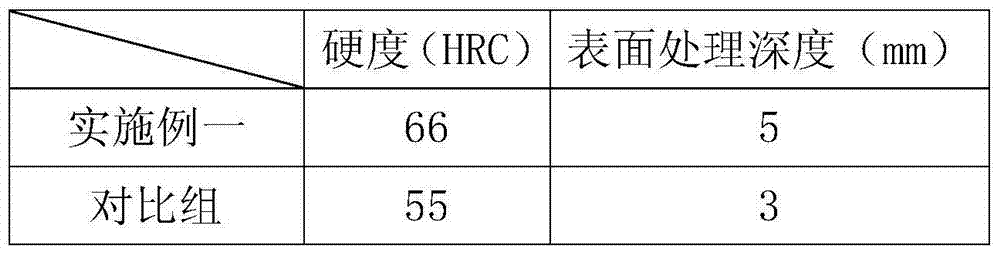

Examples

Embodiment 1

[0016] A laser heat treatment process for a shearer shoe, comprising:

[0017] (1) Pre-treatment: Clamp the shoe on the machine tool, clean the working surface of the shoe and the oil and rust on the outer surface of the shoe;

[0018] (2) Phosphating: Phosphating treatment is carried out on the surface of the slide shoe;

[0019] (3) sand blasting: if the damage on the surface of the sliding shoe is dark, then select electric arc or spray welding to make the bottom; select nickel-chromium-aluminum wire for use when the described electric arc makes the bottom; select Ni60 wire for use when the described spray welding makes the bottom;

[0020] (4) Observe and measure the range of the slide shoe to be repaired, program in the control cabinet according to the measurement results, write the scanning speed and rotation speed into the PLC control system, and adopt automatic control to realize real-time control of laser cladding, The quality of cladding is ensured, and compared wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com