A kind of water-based lubricant for papermaking and preparation method thereof

A lubricant and water-based technology, which is applied in papermaking, textiles and papermaking, and the addition of paper forming aids, can solve the problems of carcinogenicity, insignificant lubricant comprehensive effect, and poisonous epichlorohydrin, so as to improve lubricating performance, Reduce friction coefficient, good performance of lubricant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

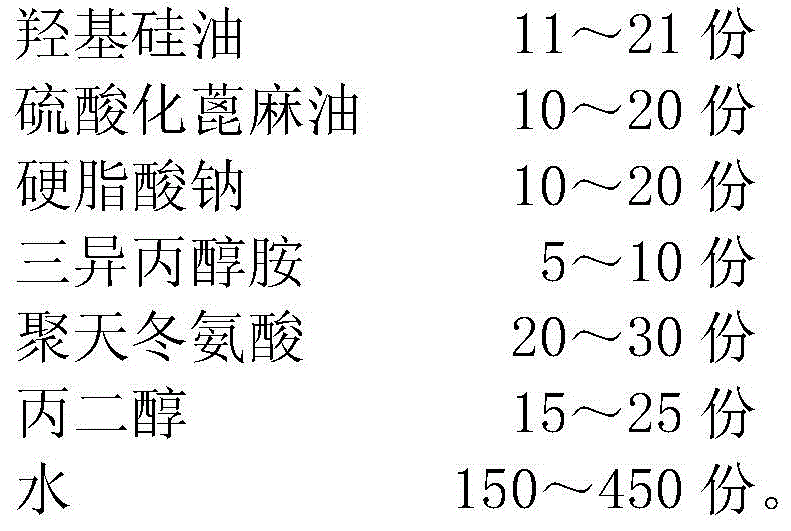

Method used

Image

Examples

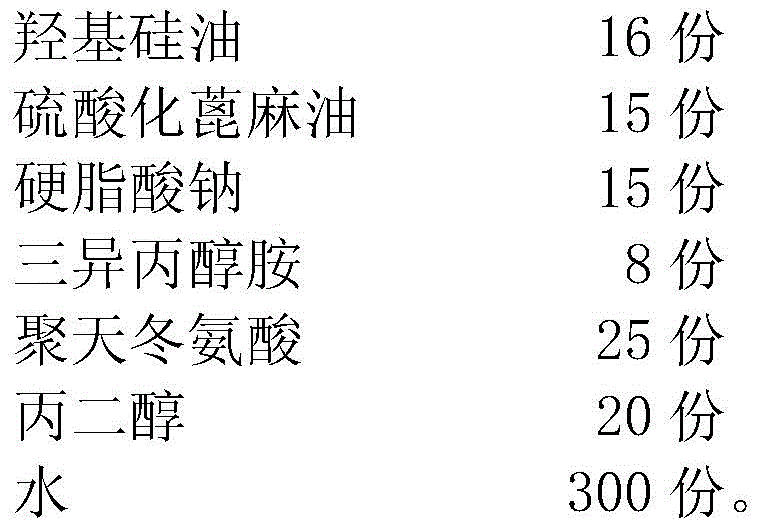

Embodiment 1

[0023] Add 450 parts by weight of prepared water into the reaction kettle, raise the water temperature to 95°C, keep it for 5 minutes, cool down to 45°C, then add 11 parts by weight of hydroxyl silicone oil, 20 parts by weight of sulfated castor oil, and 10 parts by weight of stearin Na2SO4 and 10 parts by weight of triisopropanolamine, heat-retain for 100 minutes, then cool down to 30°C, then add 20 parts by weight of polyaspartic acid and 25 parts by weight of propylene glycol, heat-retain for 80 minutes, and cool down to room temperature.

Embodiment 2

[0025] Add 400 parts by weight of prepared water into the reactor, raise the water temperature to 96°C, keep it for 4 minutes, cool down to 50°C, then add 13 parts by weight of hydroxyl silicone oil, 18 parts by weight of sulfated castor oil, and 12 parts by weight of stearin Na2SO4 and 8 parts by weight of triisopropanolamine, heat-retain for 90 minutes, then cool down to 33°C, then add 21 parts by weight of polyaspartic acid and 24 parts by weight of propylene glycol, heat-retain for 70 minutes, and cool down to room temperature.

Embodiment 3

[0027] Add 350 parts by weight of prepared water into the reactor, raise the water temperature to 97°C, keep it for 3 minutes, cool down to 48°C, then add 15 parts by weight of hydroxyl silicone oil, 16 parts by weight of sulfated castor oil, and 14 parts by weight of stearin Na2SO4 and 9 parts by weight of triisopropanolamine, heat-retain for 80 minutes, then lower the temperature to 35°C, then add 23 parts by weight of polyaspartic acid and 22 parts by weight of propylene glycol, heat-retain for 60 minutes, and then cool down to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com