System and method for capturing coal-fired power plant CO2 by use of molten carbonate fuel cell

A technology of molten carbonate and coal-fired power plants, applied in fuel cells, separation methods, chemical instruments and methods, etc., to achieve the effects of improving efficiency, reducing energy consumption, and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

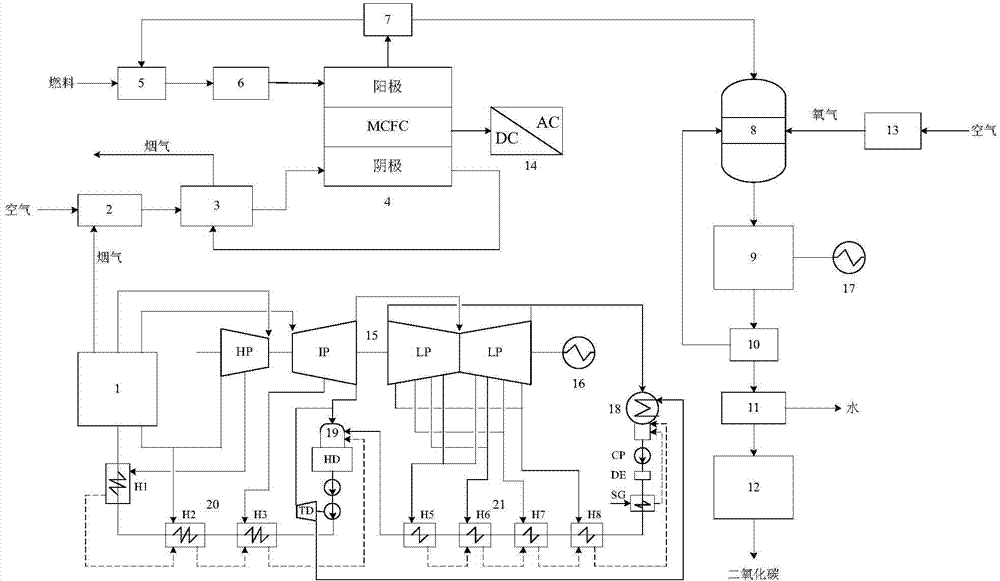

[0029] The invention provides a method for capturing CO in a coal-fired power plant with a molten carbonate fuel cell 2 The system and method of the present invention will be further described below through the description of the drawings and specific implementation methods.

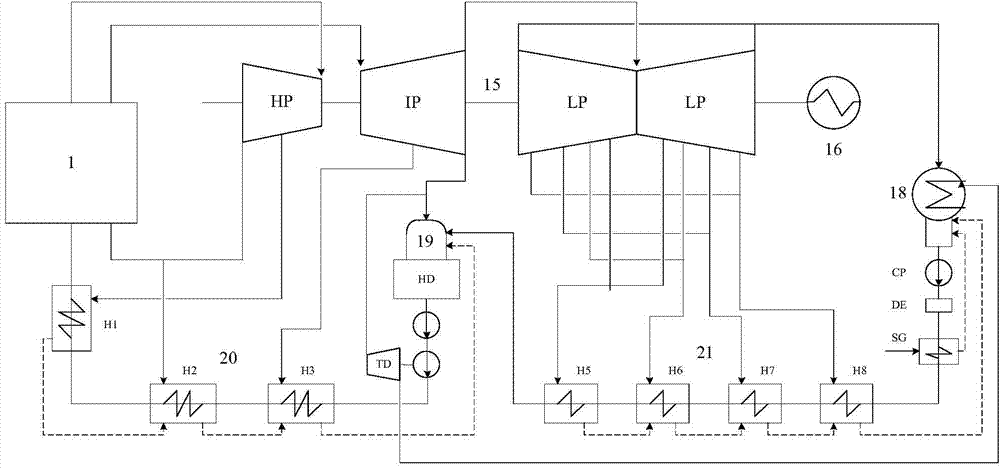

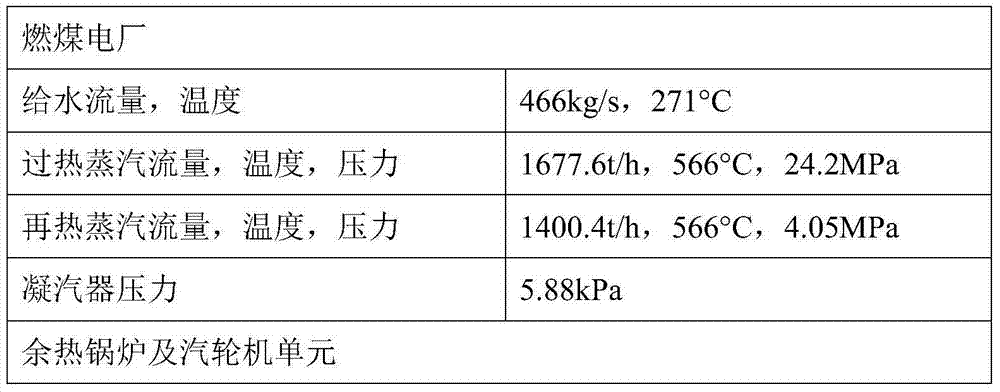

[0030] Does not recover CO 2 The conventional coal-fired power plant system flow such as figure 1shown. The high-temperature flue gas is heated in the coal-fired power plant boiler 1 to the feedwater in the water wall and the saturated steam in the superheater to become superheated steam, and then passes through the economizer and air preheater to heat the feedwater and air in the economizer to preheat The air in the device is discharged into the atmosphere after desulfurization and dust removal. The superheated steam from the boiler 1 of the coal-fired power plant enters the steam turbine unit 15 of the coal-fired power plant to do work. After the work, the exhaust steam and condensed water meet in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com