In situ pressure loading device for neutron small-angle scattering

A small-angle scattering and loading device technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of small thickness and size, and achieve reliable performance, simple structure, and high measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

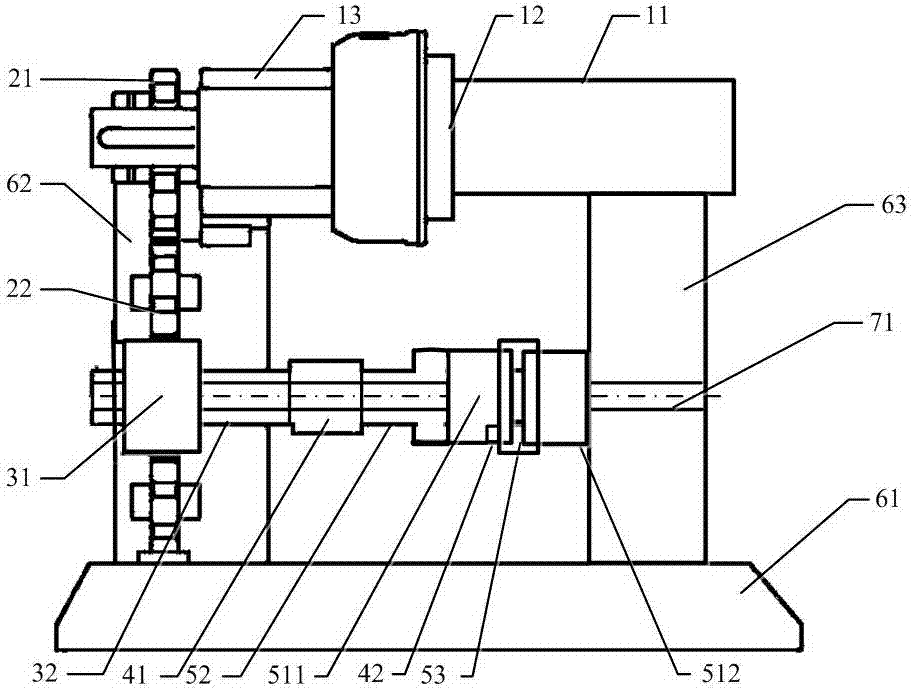

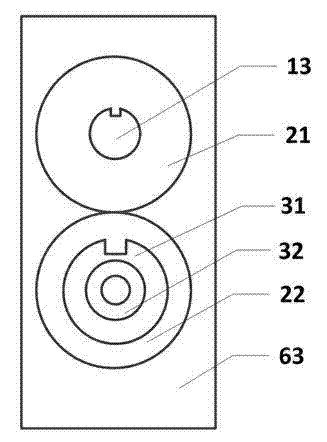

[0027] figure 1 It is a structural schematic diagram of the in-situ pressure loading device for small-angle neutron scattering of the present invention, figure 2 It is the left view of the in-situ pressure loading device for small-angle neutron scattering of the present invention, image 3 It is a schematic structural diagram of the mobile end fixture in the present invention, Figure 4 It is a structural schematic diagram of the fixed end clamp in the present invention, Figure 5 It is a schematic structural diagram of the sample cladding in the present invention. exist Figure 1 to Figure 5 Among them, the in-situ pressure loading device for neutron small-angle scattering of the present invention includes a power drive assembly, a transmission gear assembly, a ball screw assembly, a high-precision measurement assembly, a fixture assembly, a fixed frame base assembly and a shielding layer.

[0028]The power drive assembly includes a servo motor 11 , an encoder 12 and a r...

Embodiment 2

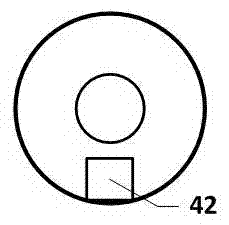

[0037] The structure of this embodiment is the same as that of Embodiment 1, except that the mechanical sensor 41 in the high-precision measurement component has a hollow inner diameter of 18mm, a measurement range of 0-5 kN, and a measurement accuracy of 0.5%; the non-contact displacement sensor 42 Replace it with a high-precision capacitive displacement sensor. The measurement accuracy of the capacitive displacement sensor is 0.01um, and the measurement range is 0~0.2mm. The capacitive displacement sensor includes a first capacitor plate and a second capacitor plate. The first capacitor plate is installed on the The lower end of the fixture at the movable end, and the second capacitor plate is installed at the lower end of the fixture at the fixed end. The lower ends of the movable end fixture 511 and the fixed end fixture 512 are respectively provided with fixed installation grooves matching the first capacitor plate and the second capacitor plate. The sample enclosure 53, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com