System and method for producing food-grade carbon dioxide from lime kiln tail gas

A carbon dioxide and lime kiln technology, applied in chemical instruments and methods, separation methods, production of bulk chemicals, etc., can solve the problems of ineffective and rational utilization of resources and great environmental hazards, and achieve improved competitiveness, increased benefits, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

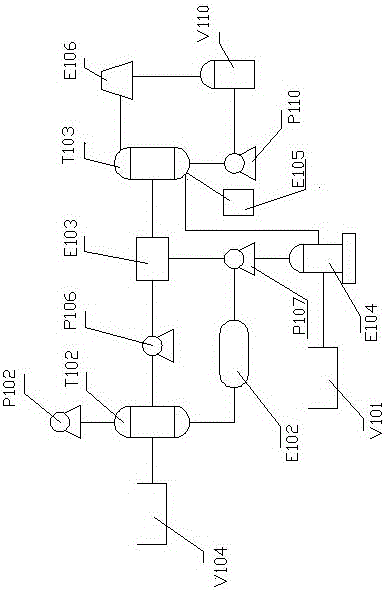

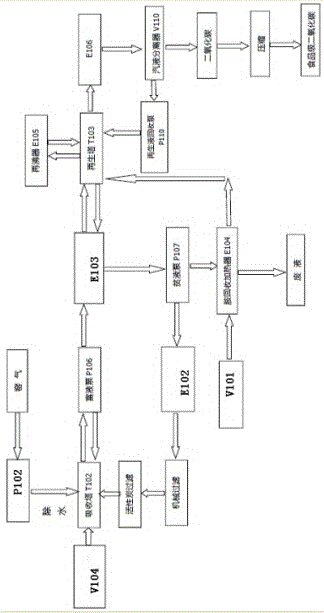

Image

Examples

Embodiment 1

[0032] Example 1 - Preparation of food-grade carbon dioxide:

[0033] A. Lime kiln exhaust gas from outside the boundary, with a gas volume of 9000 Nm 3 , mass percentage content 22%, pressure at 3 kPa, temperature 32 ℃, after entering the water ring vacuum pump P102 to pressurize to 50 kPa, after dehydration, sent to the carbon dioxide absorption tower T102, the CO in the tail gas 2 Absorbed and dissolved in ethanolamine solution (MEA) solution;

[0034] B. The MEA rich liquid treated from the bottom of the absorption tower T102 is introduced into the rich liquid pump P106, pressurized to 0.6 MPa, and then sent to the poor-rich liquid heat exchanger E103 to raise the temperature to 95 °C and enter the top of the carbon dioxide regeneration tower T103, and the bottom of the regeneration tower T103 Set a reboiler E105 to use steam heating, control the temperature of the tower tank at 120 ℃, 0.15MPa, the temperature of the tower top at 95 ℃, 0.12 Mpa; the flow rate of the rich ...

Embodiment 4

[0042] Embodiment 4-preparation of food grade carbon dioxide:

[0043] A. Lime kiln tail gas, gas volume 15000Nm 3 , the content is 25%, the pressure is 4 kPa, the temperature is 36 ℃, after entering the water ring vacuum pump P102 to pressurize to 52kPa, after removing water, it is sent to the carbon dioxide absorption tower T102, the CO in the tail gas 2 Absorbed and dissolved in MEA solution;

[0044] B. The MEA rich liquid treated at the bottom of the absorption tower T102 is introduced into the rich liquid pump P106, pressurized to 0.62 MPa, and then sent to the poor-rich liquid heat exchanger E103 to raise the temperature to 100 ℃, enter the top of the carbon dioxide regeneration tower T103, and the bottom of the regeneration tower T103 Set a reboiler E105 to use steam heating, control the temperature of the tower bottom at 125 °C, 0.17MPa, and the temperature of the tower top at 100 °C, 0.14MPa. The flow rate of the rich solution pump (P106) is 85m 3 / h.

[0045] C....

Embodiment 7

[0052] Example 7 - Preparation of food-grade carbon dioxide:

[0053] A. Lime kiln tail gas, gas volume 13000Nm 3 , the content is 24%, the pressure is 5 kPa, the temperature is 40 ℃, after entering the water ring vacuum pump P102 to pressurize to 48kPa, after removing water, it is sent to the carbon dioxide absorption tower T102, the CO in the tail gas 2 absorbed and dissolved in MEA solution,

[0054] B. The MEA rich liquid treated from the bottom of the absorption tower T102 is introduced into the rich liquid pump P106, pressurized to 0.58 MPa, and then sent to the poor-rich liquid heat exchanger E103 to raise the temperature to 105 °C and enter the top of the carbon dioxide regeneration tower T103, and the bottom of the regeneration tower T103 Set a reboiler E105 to use steam heating, control the temperature of the tower bottom at 130°C, 0.13MPa, and the temperature of the tower top at 105°C, 0.10MPa. The flow rate of the rich solution pump (P106) is 75m 3 / h.

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com