Surface-coated cutting tool with excellent abnormal damage resistance and wear resistance

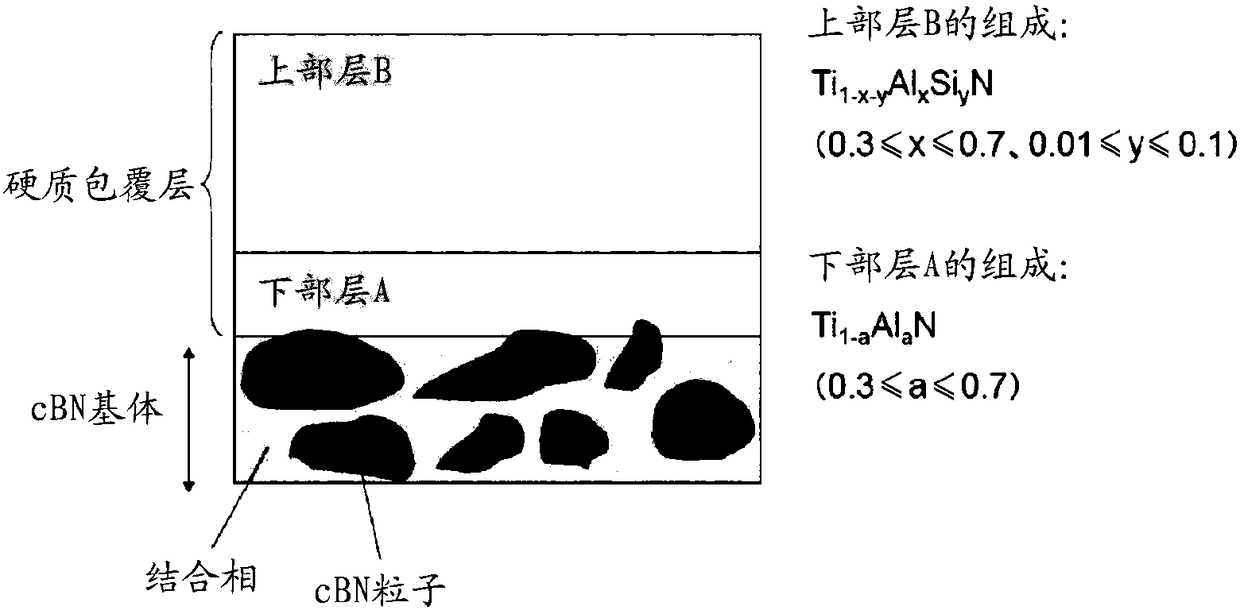

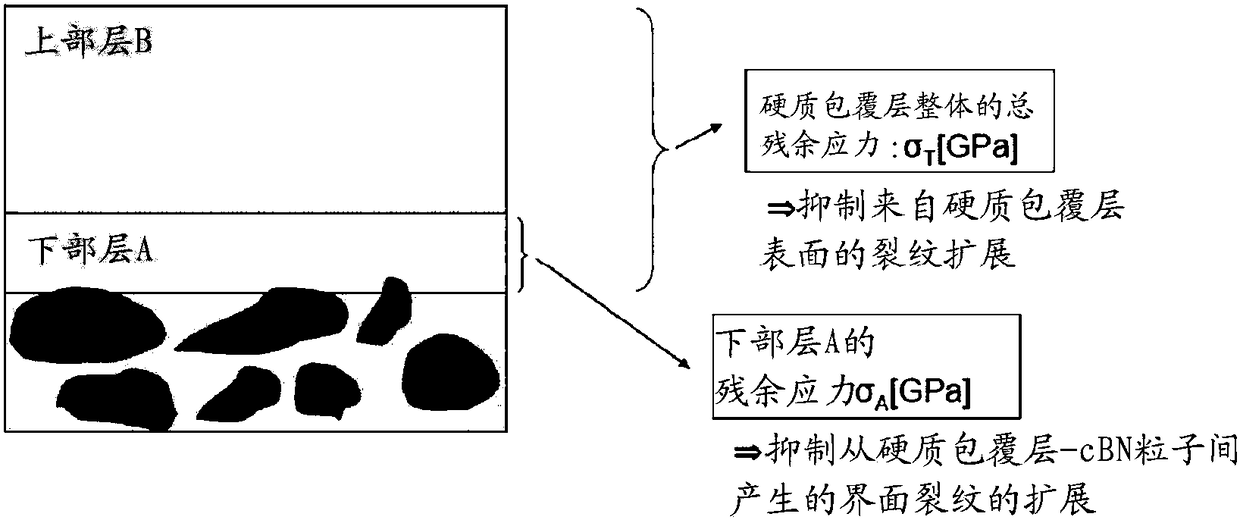

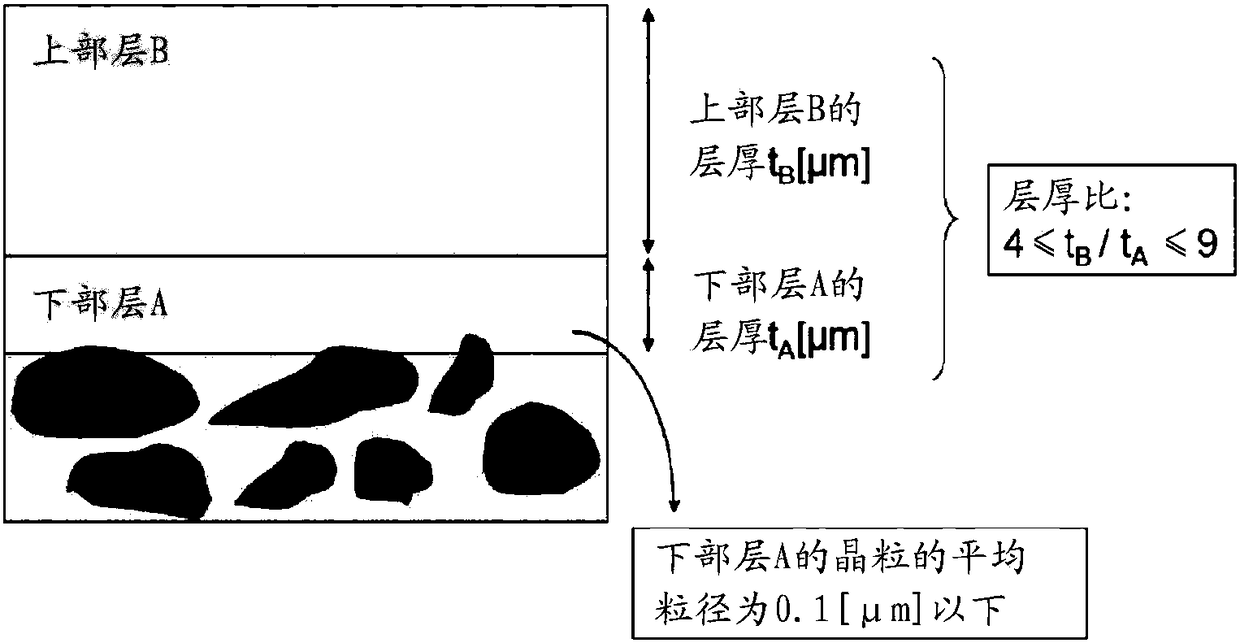

A cutting tool and surface coating technology, applied in the field of surface coating cutting tools, can solve the problems of reducing chipping, short tool life, insufficient wear resistance, etc., and achieve the effect of improving defect resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Production of the tool base:

[0082] As the raw material powder, prepare cBN particles having an average particle diameter of 0.5 to 4.0 μm as the raw material powder for forming a hard phase, and prepare TiN powder, TiC powder, and TiCN powder each having an average particle diameter in the range of 0.3 to 0.9 μm. , Al powder, AlN powder, Al 2 o 3 The powder is used as a raw material powder for forming a binder phase.

[0083] The compounding ratio shown in Table 1 was compounded so that the content ratio of the cBN particle powder when the total amount of some of these raw material powders and cBN particle powder was 100 volume % became 40-70 volume %.

[0084] Next, wet-mix the raw material powder with a ball mill for 72 hours, and after drying, use a press to press 1 MPa to extrude according to the size of diameter: 50mm×thickness: 1.5mm, and then press the molded body under the pressure: In a vacuum atmosphere below 1 Pa, heat treatment is performed at 1000°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com