Polyolefin plastics fibrillation raw material production set special for wood plastic composite material

A wood-plastic composite material and polyolefin fiber technology, which is applied in the field of production units for polyolefin plastic thinning raw materials for wood-plastic composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

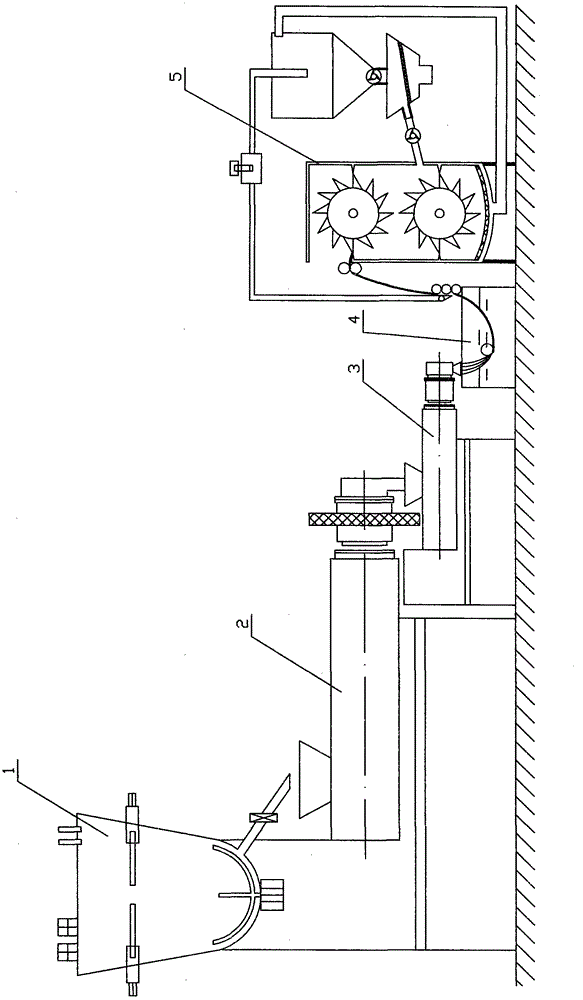

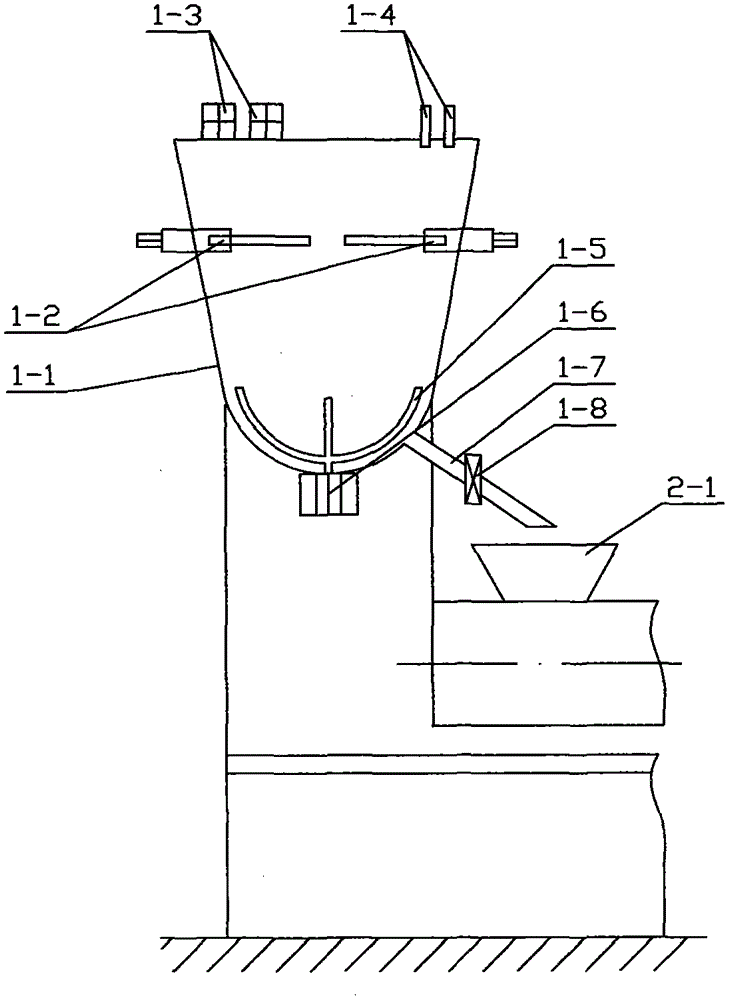

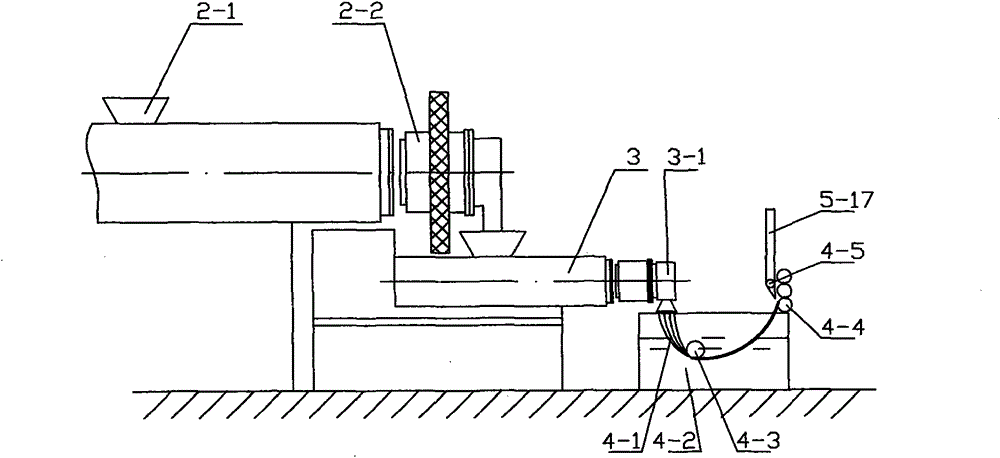

[0021] exist figure 1 In, a special mixer with automatic feeding and precise metering and separation system (1) is connected with a plastic extruder with a filter system (2), and a plastic extruder with a filter system (2) is connected with a belt A plastic extruder (3) with a spinning die, a plastic extruder (3) with a spinning die connected to a stretching machine (4) with a water-cooled air cleaning system, and a stretching machine with a water-cooled air cleaning system Machine (4) connects and cuts off air-drawing screening machine (5). When working, the raw materials of the set formula are mixed in a special mixer (1) with automatic feeding and precise metering and separation system, and then enter the plastic extruder (2) with a filtration system, and are extruded and filtered The final melt enters the plastic extruder (3) with a spinning die, and the extruded filamentary material is stretched and cooled by a stretching machine (4) with a water-cooled air cleaning syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com