rc microporous composite digital photo paper and its production process

A technology for digital photographic paper and production process, applied in the field of digital photographic paper, can solve problems such as affecting work efficiency, unsatisfactory glossiness on the surface of photographic paper, affecting aesthetic effects, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

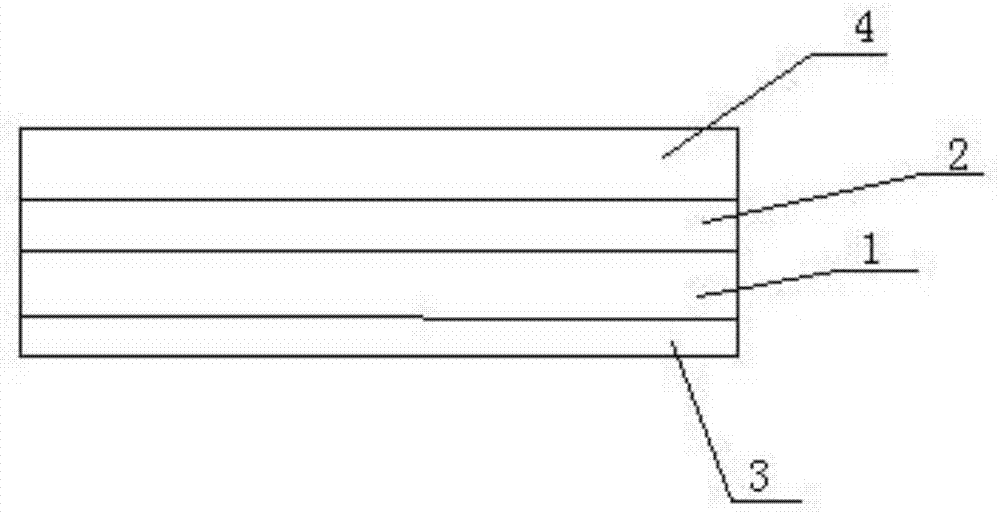

Image

Examples

specific Embodiment 1

[0034] A kind of production technology of described RC microporous composite digital photographic paper, comprises the steps:

[0035] (1) Composite process:

[0036] a. On the dry compound machine, cover the front side of the RC paper base with PET film;

[0037] b. On the dry compound machine, cover the back of the RC paper base with OPP matt film;

[0038] (2) Coating process:

[0039] Put the above-mentioned composite paper coated on both sides on the wave flow extrusion coating machine, and apply the pre-prepared coating liquid on the surface of the PET film through the extrusion nozzle on the coating machine to form a polymer coating layer. , The amount of coating is 200g when wet coating and 38g after drying. Then drying is carried out, specifically: put the coated composite paper into a drying box, and dry it for 15 minutes at a temperature of 90° C. to make RC microporous composite digital photo paper.

[0040] The preparation of the coating solution in the step (...

specific Embodiment 2

[0041] A kind of production technology of described RC microporous composite digital photographic paper, comprises the steps:

[0042] (1) Composite process:

[0043] a. On the dry compound machine, cover the front side of the RC paper base with PET film;

[0044] b. On the dry compound machine, cover the back of the RC paper base with OPP matt film;

[0045] (2) Coating process:

[0046] Put the above-mentioned composite paper coated on both sides on the wave flow extrusion coating machine, and apply the pre-prepared coating liquid on the surface of the PET film through the extrusion nozzle on the coating machine to form a polymer coating layer. , The amount of coating is 200g when wet coating and 38g after drying. Then dry it, specifically: put the coated composite paper into a drying oven, and dry it for 15 minutes at a temperature of 120° C. to make RC microporous composite digital photo paper.

[0047] The preparation of the coating solution in the step (2) is as foll...

specific Embodiment 3

[0048] A kind of production technology of described RC microporous composite digital photographic paper, comprises the steps:

[0049] (1) Composite process:

[0050] a. On the dry compound machine, cover the front side of the RC paper base with PET film;

[0051] b. On the dry compound machine, cover the back of the RC paper base with OPP matte film;

[0052] (2) Coating process:

[0053] Put the above-mentioned composite paper coated on both sides on the wave flow extrusion coating machine, and apply the pre-prepared coating liquid on the surface of the PET film through the extrusion nozzle on the coating machine to form a polymer coating layer. , The amount of coating is 200g when wet coating and 38g after drying. Then dry it, specifically: put the coated composite paper into a drying oven, and dry it for 15 minutes at a temperature of 110° C. to make RC microporous composite digital photo paper.

[0054] The preparation of the coating solution in the step (2) is as follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com