Method for preparing cetrorelix acetate through specific microwave synthesis

A technology of cetrorelix acetate and microwave synthesis, which is applied in the field of polypeptide drug preparation and can solve problems such as human body injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Swelling of amino resin

[0026] Weigh 0.15g of Rink-AM-Resin with a degree of substitution of 0.97-1.04mmol / g, add it to the polypeptide synthesis reactor from the open end, take the DCM reagent and add it to the reactor, so that the resin is completely immersed in the DCM solvent. Fully exposed to the solvent, swelling for 2h.

[0027] 2. Synthesis of Fmoc-cetrorelix resin

[0028] The cetrorelix precursor peptide I-amino resin is:

[0029] Fmoc-D-Nal-D-Cpa-D-Pal-Ser-Tyr-D-Cit-Leu-Arg-Pro-D-Ala-Amino Resin

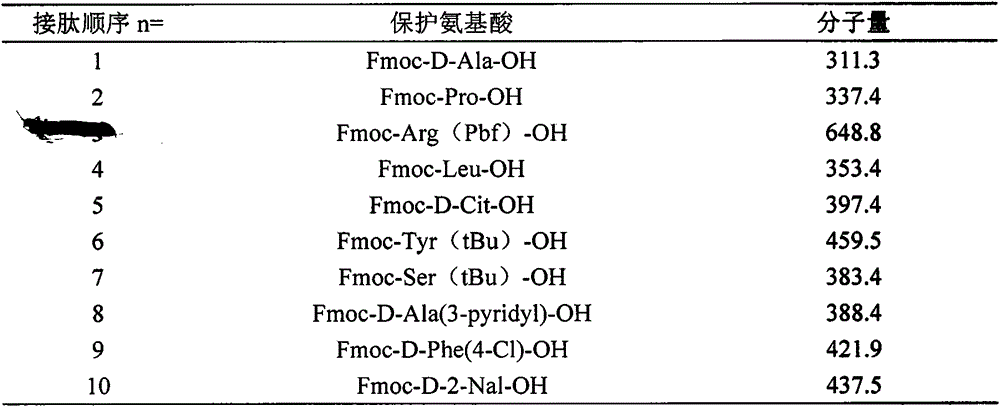

[0030] The protected amino acids used in this example are listed in the table below for the protected amino acids and molecular weights corresponding to the 1st to 10th amino acids from the resin:

[0031]

[0032] Some commonly used abbreviations in the present invention have the following meanings:

[0033] Fmoc: fluorenylmethoxycarbonyl 3-pyridyl-D-Ala: 3-D-phenylalanine DMF: N,N-dimethylformamide

[0034] D-Cit: D-Citrulline pbf: 2,2,4,6,7-Pentameth...

Embodiment 2

[0050]The present invention has carried out the comparative experiment of the yield of cetrorelix preparation method, namely condensation reaction 1. wash after normal condensation reaction 20~30min; 20~25min after normal condensation reaction, add 0.5ml DIEA, wash after microwave amino resin 25s; The yields of the crude cetrorelix synthesized by the above experimental method were ① 82.7%, ② 91.8%. After purification and salt conversion, the pure cetrorelix acetate ① 24.1mg, ② 31.5mg were obtained. The rates are ①31.8% and ②41.2%.

Embodiment 3

[0052] The present invention has carried out secondary repeated synthesis, to confirm the stability of experimental result, condensation reaction 1. wash after 20~30min of normal condensation reaction 20~25min after normal condensation reaction, add 0.5ml DIEA, wash after microwave amino resin 25s; Obtain The purity of the crude product of cetrorelix reached 83%, and the yields of the crude product were ①83.1% and ②92.4%. After purification and salt conversion, the pure cetrorelix acetate ①24.3mg and ②31.3mg were obtained. The rate is ①32.4%, ②40.7%; confirming the correctness and stability of the experimental data of the present invention.

[0053] Through the experiment of the above-mentioned Example 2 and Example 3, it can be concluded that after normal synthesis and then microwave reaction, the yield of pure cetrorelix acetate prepared is higher and the effect is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com