High-CTI (comparative tracking index) and high-light diffusivity flame-retardant PC (polycarbonate) compound and preparation method thereof

A compound and diffusion technology, which is applied in the field of high CTI, high light diffusivity flame retardant PC compound and its preparation, can solve problems such as the CIT value of unrelated materials, achieve excellent light diffusion performance and flame retardant performance, super high Effect of Tracking Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

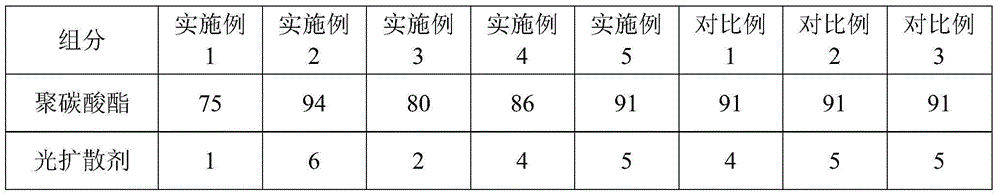

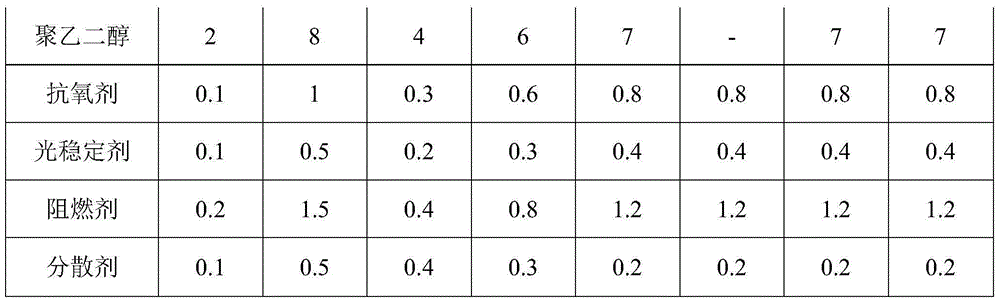

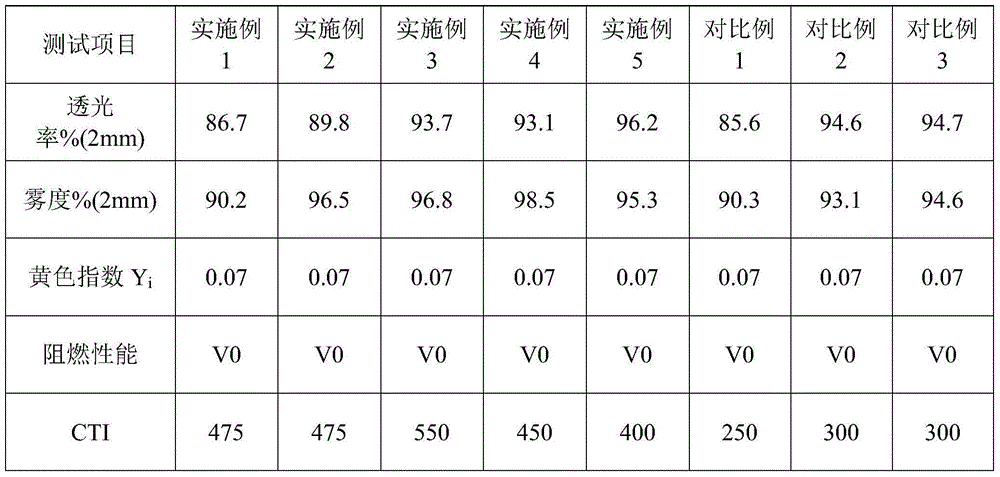

Embodiment 1

[0023] A flame-retardant PC composite material with high CTI and high light diffusivity, prepared from the following components and contents: 75 parts of polycarbonate, 1 part of light diffusing agent, 2 parts of polyethylene glycol, 0.1 part of antioxidant, 0.1 part of light stabilizer, 0.2 part of flame retardant, and 0.1 part of dispersant. The polycarbonate is a highly transparent polycarbonate; the light diffusing agent is microspherical calcium carbonate; the antioxidant is a phenolic antioxidant; the light stabilizer is a light shielding agent; Described dispersant is PE wax; Described flame retardant is the compounding of brominated polystyrene and ammonium polyphosphate by weight 1:1; Described polyethylene glycol is the PEG- 1000 (molecular weight 900 to 1100). Preparation method: weigh each raw material according to the proportion; put the above raw materials into a high-mixer and mix for 3-5 minutes, then discharge to obtain a mixture, and then control the process...

Embodiment 2

[0025] A flame-retardant PC composite material with high CTI and high light diffusivity, prepared from the following components and contents: 95 parts of polycarbonate, 6 parts of light diffusing agent, 8 parts of polyethylene glycol, 1 part of antioxidant, 0.5 parts of light stabilizer, 1.5 parts of flame retardant, and 0.5 parts of dispersant. The polycarbonate is a highly transparent polycarbonate; the light diffusing agent is microspherical silicon dioxide; the antioxidant is a phosphorus antioxidant; the light stabilizer is an ultraviolet absorber; Described dispersant is EVA wax; Described flame retardant is the composite of brominated polystyrene and ammonium polyphosphate by weight 1:1; Described polyethylene glycol is the PEG of Nantong Taichen Chemical Co., Ltd. -1500 (molecular weight of 1350 to 1650). Preparation method: weigh each raw material according to the proportion; put the above raw materials into a high-mixer and mix for 3-5 minutes, then discharge to obt...

Embodiment 3

[0027] A flame-retardant PC composite material with high CTI and high light diffusivity, prepared from the following components and contents: 80 parts of polycarbonate, 2 parts of light diffusing agent, 4 parts of polyethylene glycol, 0.3 parts of antioxidant, 0.2 parts of light stabilizer, 0.4 parts of flame retardant, and 0.4 parts of dispersant. The polycarbonate is a highly transparent polycarbonate; the light diffusing agent is microspherical barium sulfate; the antioxidant is a sulfur-based antioxidant; the light stabilizer is a quencher; Described dispersant is OP wax; Described flame retardant is the composite of brominated polystyrene and ammonium polyphosphate by weight 1:1; Described polyethylene glycol is the PEG- 2000 (molecular weight of 1800 to 2200). Preparation method: weigh each raw material according to the proportion; put the above raw materials into a high-mixer and mix for 3-5 minutes, then discharge to obtain a mixture, and then control the processing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com