Adhesive composition for plywood and preparation process of adhesive composition

A technology of adhesives and compositions, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve problems such as production restrictions, harm to health, and production costs that cannot be greatly reduced, and achieve the end of curing time and use long life effect

Inactive Publication Date: 2015-08-26

ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the adhesives used in plywood production are still mainly formaldehyde-based adhesives, of which phenolic resin adhesives are mostly used to produce outdoor type I plywood, and urea-formaldehyde resin adhesives are mostly used to produce indoor type II plywood. In the process of production and use, free formaldehyde will be released from the connected products, which will endanger people's health. As consumers' awareness of environmental protection is increasing, the production of formaldehyde-based adhesives, especially urea-formaldehyde resin adhesives for bonding indoor products, is subject to increasingly strict restrictions

The release of harmful formaldehyde gas can be reduced by improving the production process of urea-formaldehyde resin glue, or adopting appropriate post-treatment methods for the bonded products, but this not only increases the cost, but also cannot completely solve the problem of free formaldehyde release

[0003] In the article "Development of Hot-pressed Starch-based Waterborne Isocyanate Wood Adhesive" published in the Journal of Northeast Forestry University 2008-7, it was introduced that "a wood adhesive with a large amount of annual cornstarch as the main raw material and high comprehensive performance ", but the preparation process of this adhesive is complicated, and the production cost cannot be greatly reduced

Patent No. 200410017054.5 introduces a wood adhesive with vegetable protein as the main raw material and its preparation method, but the wood adhesive prepared by this formula and method has poor water resistance, and there is a lack of product quality in industrial production. Stability, and the pressure of the hot-pressed thermometer required for plate production is high, and the quality of the produced plate is difficult to guarantee

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

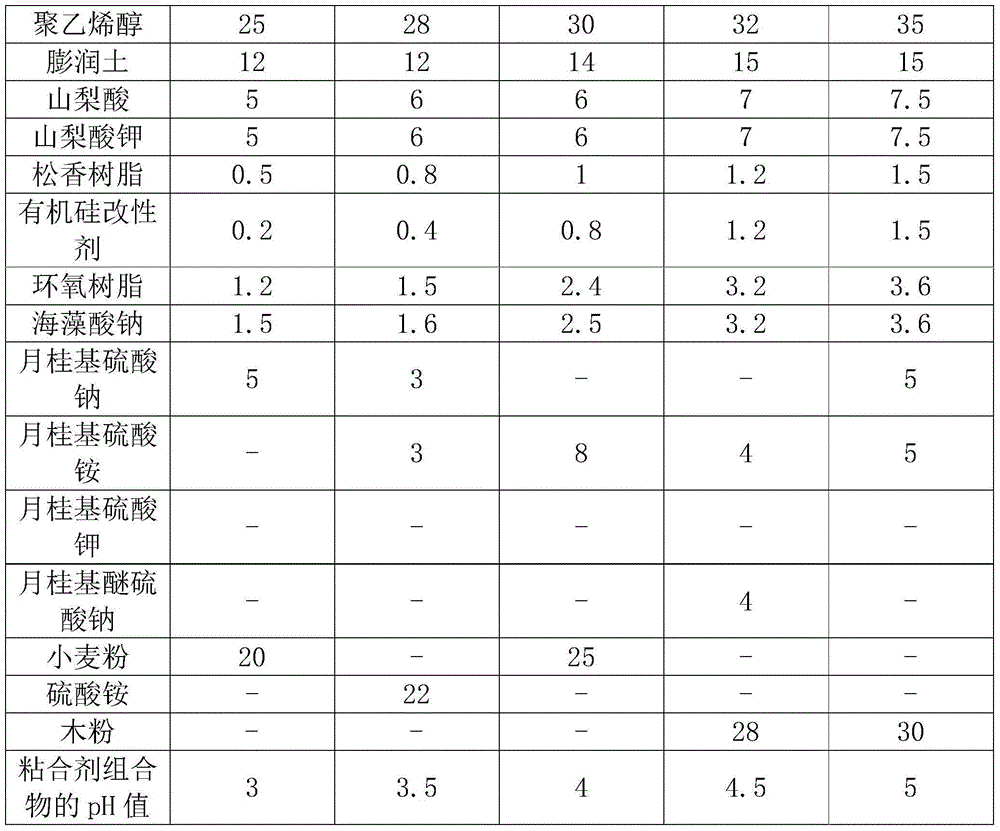

[0026] Embodiment 3 is the best implementation mode.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

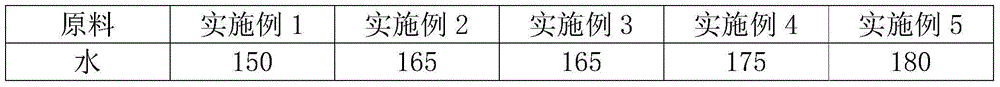

The invention relates to the technical field of adhesives, in particular to an adhesive composition for plywood and a preparation process of the adhesive composition. The adhesive composition comprises the following substances in parts by mass: 150-180 parts of water, 25-35 parts of polyvinyl alcohol, 12-15 parts of bentonite, 10-15 parts of a preservative, 0.5-1.5 parts of rosin resin, 0.2-1.5 parts of an organic silicane modifier, 1.2-3.6 parts of epoxy resin, 1.5-3.6 parts of sodium alginate, 5-10 parts of a foaming agent, and 20-30 parts of a filler; the pH value of the adhesive composition is 3-5. The adhesive composition and the preparation process have the benefits that the use of toxic substances such as formaldehyde, benzene and methylbenzene is avoided, the requirement of people on green building materials and costly furniture in house decoration is met, the adhesive composition is suitable for people requirements, the artificial playwood produced by the adhesive composition can achieve the purposes of being complete innocuous and nontoxic, and environmentally friendly. During the production process, environment pollution is avoided, and the curing time of the adhesive composition is short, and the effective life is long.

Description

technical field [0001] The invention relates to the technical field of adhesives, in particular to an adhesive composition for plywood and a preparation process thereof. Background technique [0002] At present, the adhesives used in plywood production are still mainly formaldehyde-based adhesives. Among them, phenolic resin adhesives are mostly used to produce outdoor type I plywood, and urea-formaldehyde resin adhesives are mostly used to produce indoor type II plywood. In the process of production and use, free formaldehyde will be released from the connected products, which will endanger people's health. As consumers' awareness of environmental protection is increasing, the production of formaldehyde-based adhesives, especially urea-formaldehyde resin adhesives for bonding indoor products, is under pressure. increasingly strict restrictions. The release of harmful formaldehyde gas can be reduced by improving the production process of urea-formaldehyde resin glue, or ado...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09J129/04C09J193/04C09J163/00C09J105/04C09J11/08C09J11/06C09J11/04

Inventor 范佳晨赵云龙徐丹徐凯徐再赵维达

Owner ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com