Method for inducing A184Ni10Gd6 amorphous alloy to generate phase separation

An amorphous alloy and phase separation technology, which is applied in the field of inducing phase separation of Al84Ni10Gd6 amorphous alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] an induced Al 84 Ni 10 Gd 6 A method for phase separation of amorphous alloys, comprising the following steps:

[0028] (1) Prepare corrosion solution: prepare corrosion solution according to the volume fraction ratio of 27vol.% nitric acid and 73vol.% methanol, and put it in a beaker for later use.

[0029] (2) Al 84 Ni 10 Gd 6 The amorphous strip sample is placed in a beaker filled with corrosive solution, and placed at room temperature for 120 hours. When placed, the beaker needs to be sealed with a plastic wrap to reduce the volatilization of the solution.

[0030] (3) After the set time, the sample is taken out, placed in a container filled with deionized water for ultrasonic cleaning, and then the phase-separated amorphous sample can be obtained. Among them, the Al 84 Ni 10 Gd 6 The amorphous alloy strip has a width of 3 mm and a thickness of 30 μm.

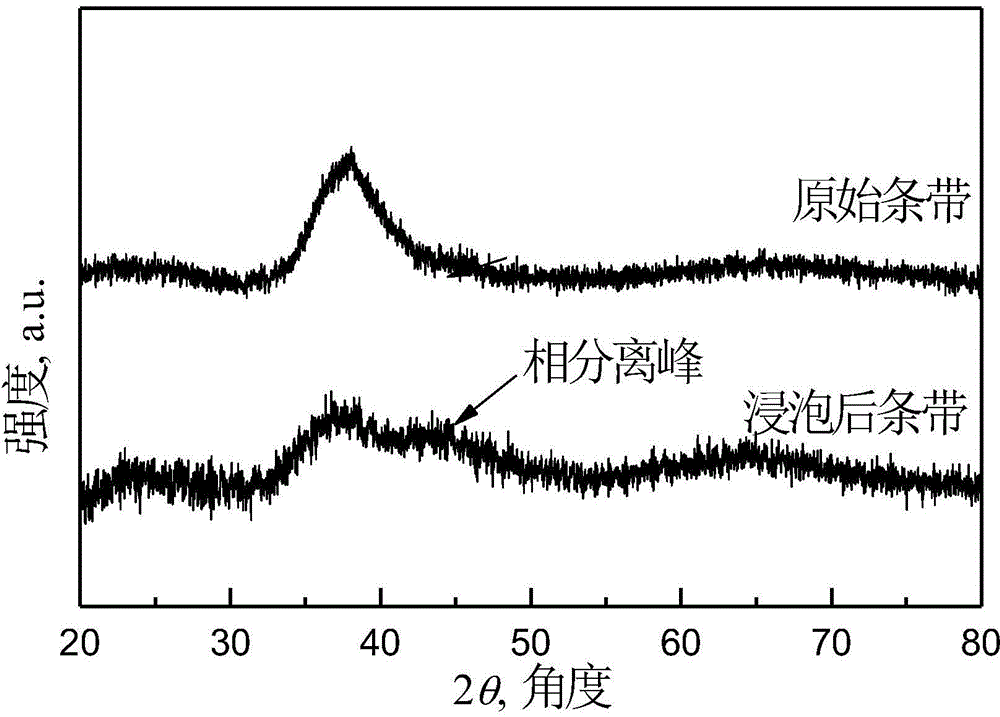

[0031] (4) Carry out XRD test to the obtained amorphous sample ( figure 1 ), it can be found that the p...

Embodiment 2

[0034] (1) Prepare corrosion solution: prepare corrosion medium according to the volume fraction ratio of 27vol.% nitric acid and 73vol.% methanol.

[0035] (2) Pour the corrosive medium into the double-jet electrolytic thinner, and then Al 84 Ni 10 Gd 6The amorphous strips were thinned in a double-jet electrolytic thinner at -20°C for 3 minutes. Among them, the Al 84 Ni 10 Gd 6 The amorphous alloy strip has a width of 3 mm and a thickness of 30 μm.

[0036] (3) After the set time, the sample is taken out, placed in a container filled with deionized water for ultrasonic cleaning, and then the phase-separated amorphous sample can be obtained.

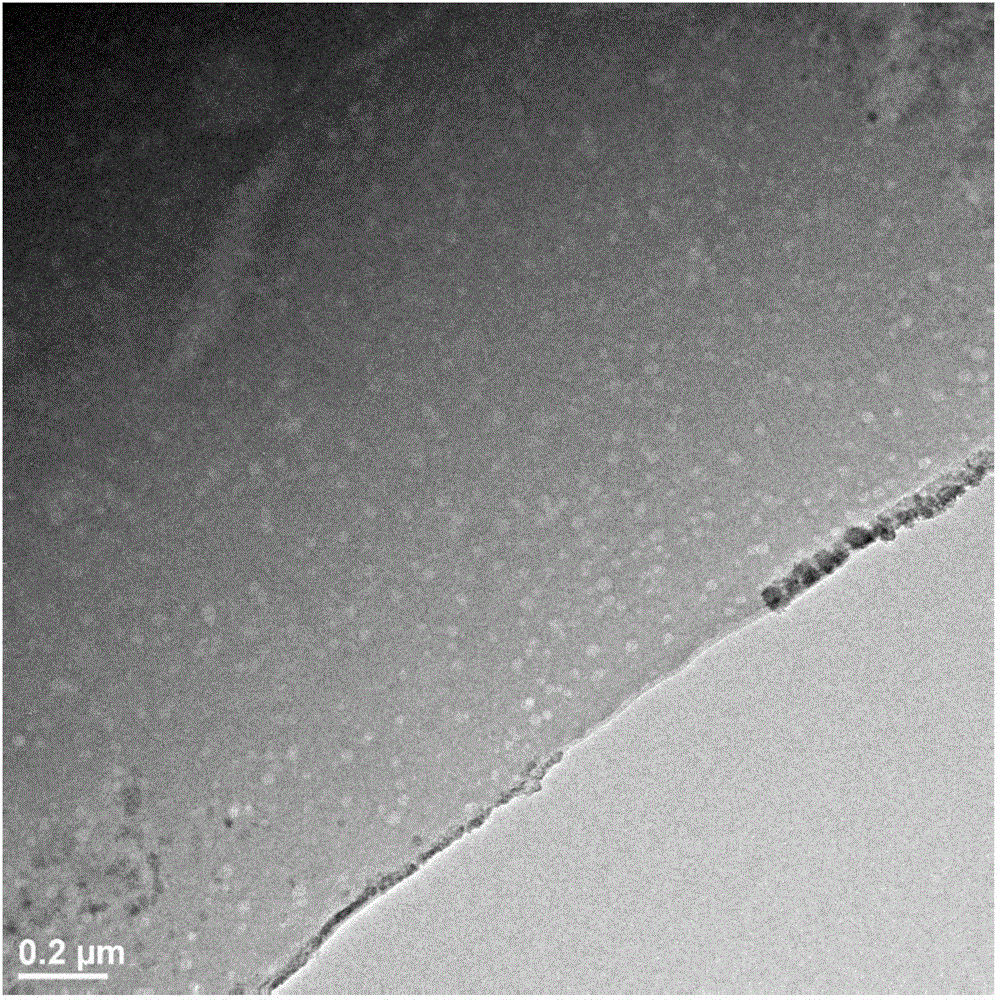

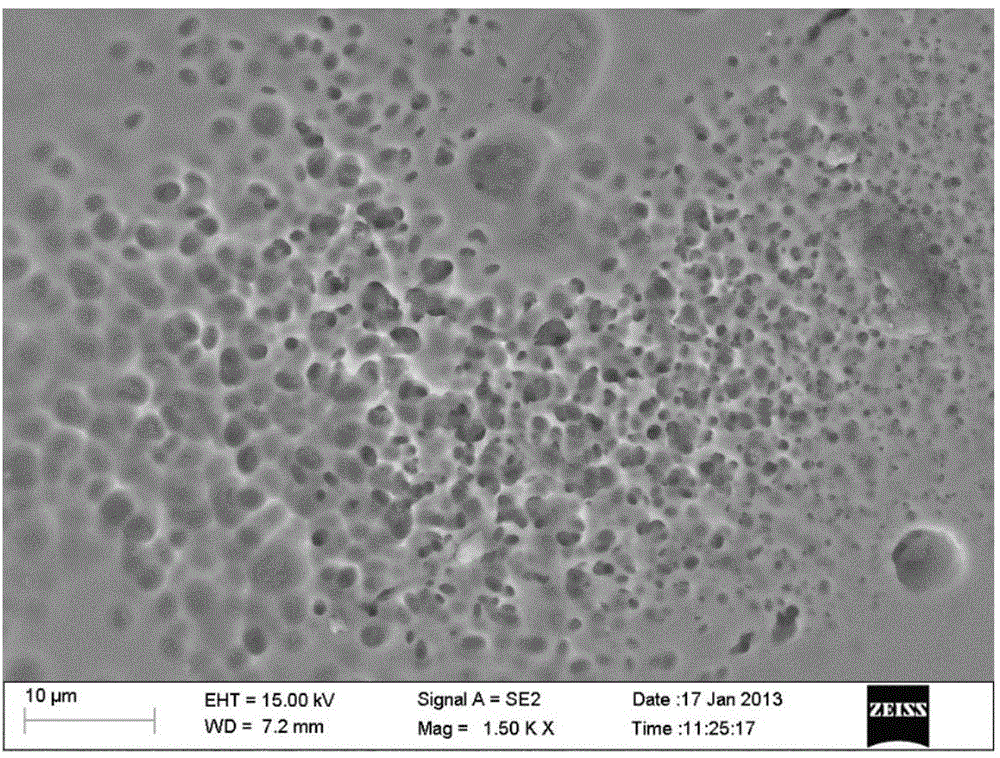

[0037] (4) carry out transmission electron microscope observation to the sample that makes, can find, such as figure 2 , the phase separation can be reflected in the dot-like structure between light and dark phases, and the measured pore size of the sample is in the range of 1 nanometer to 5 microns, and the volume percentage is ...

Embodiment 3

[0040] an induced Al 84 Ni 10 Gd 6 A method for phase separation of amorphous alloys, comprising the following steps:

[0041] (1) Prepare corrosion solution: prepare corrosion solution according to the volume fraction ratio of 20vol.% nitric acid and 80vol.% methanol, and put it in a beaker for later use.

[0042] (2) Al 84 Ni 10 Gd 6 The amorphous strip sample is placed in a beaker filled with corrosive liquid, and placed at room temperature for 100 hours. When placed, the beaker needs to be sealed with a plastic wrap to reduce the volatilization of the solution. Among them, the Al 84 Ni 10 Gd 6 The thickness of the amorphous alloy strip is 20-40 μm, and the width is 2-4 mm.

[0043] (3) After the set time, the sample is taken out, placed in a container filled with deionized water for ultrasonic cleaning, and then the phase-separated amorphous sample can be obtained.

[0044] (4) Carry out XRD test to the obtained amorphous sample, it can be found that the phase-se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com