High-strength and corrosion-resistant BMC (bulk molding compound) material anchoring system for FRP (fiber reinforced plastic) grid and anchoring method

A corrosion-resistant fiber and high-strength technology, which is applied in the field of anchoring devices, can solve problems such as poor bonding between mortar and concrete components, discounted FRP mesh use effect, and weak points of bonding, so as to achieve weak points that are not easily bonded, Good anchoring effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

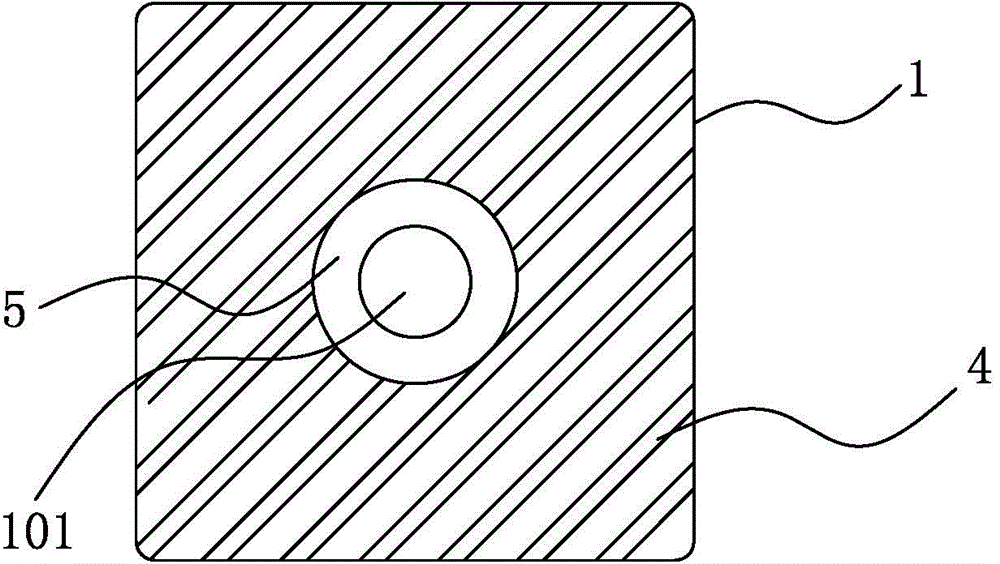

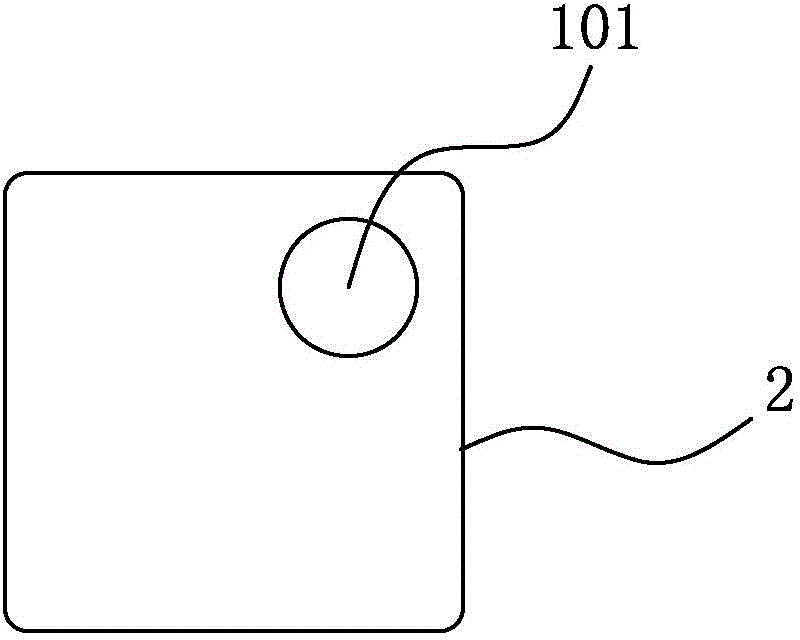

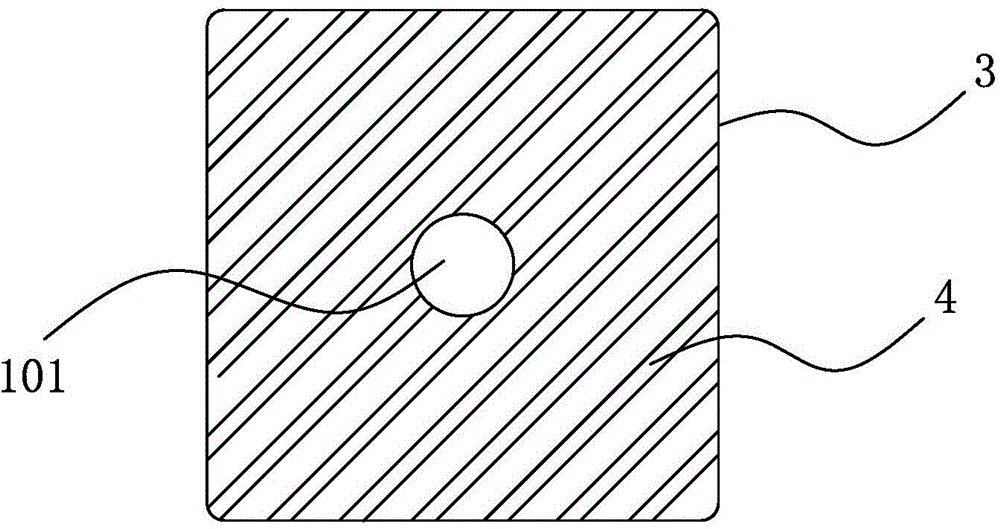

[0034] like Figure 4 , Figure 5 As shown, the high-strength, corrosion-resistant fiber grid BMC material anchoring system of the present invention includes an anchor 10 and an anchor bolt 11, and the anchor 10 includes an upper pressing piece 1, a middle fixing piece 2, and a bottom that are fixed together from top to bottom. Gasket 3, the two adjacent sides of the upper pressing piece 1 are respectively aligned with the corresponding sides of the middle fixing piece 2 and the bottom gasket 3, so that the left sides of the upper pressing piece 1, the middle fixing piece 2, and the bottom gasket 3 Located in the same plane, the front sides of the upper pressing piece 1, the middle fixing piece 2, and the bottom gasket 3 are also located in the same plane. There are uneven lines 4 on the exposed surfaces of the upper pressing piece 1 and the bottom gasket 3 , that is, the upper and lower surfaces and the front and rear sides of the anchor 10 have uneven lines 4 . These lines...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com