Dual-intelligent-optimization control method for unit load

A unit load and intelligent optimization technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problems affecting the application effect of the model, the influence of steam turbine work, and poor anti-interference ability, so as to ensure long-term safety and reliability operation, improving the load response rate, and improving the effect of deep peak shaving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

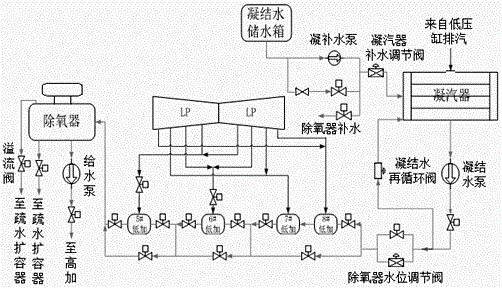

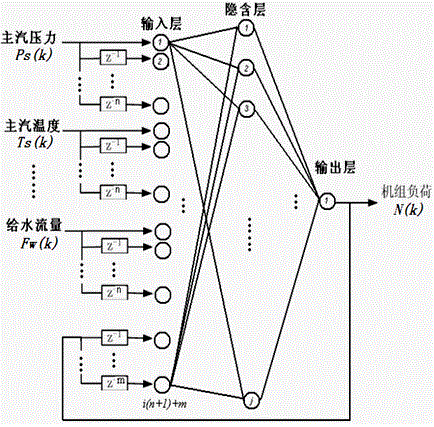

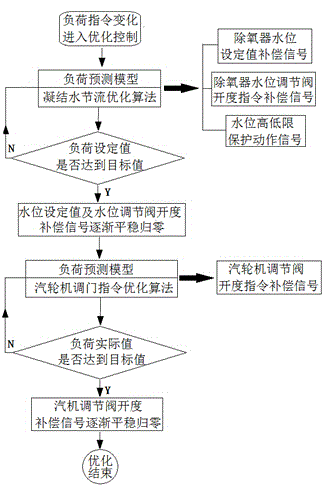

[0041] Aiming at the shortcomings of the existing Coordinated Control System (CCS) in the large supercritical units mentioned in the background technology that it is difficult to meet the fast load response requirements of the power grid, and it is easy to cause large fluctuations in parameters such as main steam pressure and main steam temperature, the present invention establishes a And condensate water throttling steam turbine unit load forecasting neural network model, and then a dual intelligent optimization control method for unit load based on intelligent model is proposed. The present invention mainly includes two parts.

[0042] 1. Establish a neural network model for load forecasting of steam turbine units that takes into account condensate throttling, including the following specific steps:

[0043] (1) Select model input and output parameters

[0044] The opening of the deaerator water level regulator is used to replace the condensate flow as the model input, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com