Suture-free bilioenteric anastomosis stent manufactured through 3D (three-dimensional) printing and manufacturing method thereof

A 3D printing, biliary and intestinal technology, applied in the field of medical surgical supplies, can solve problems such as affecting tissue blood supply, poor bile duct plasticity, and unsuitability for clinical use, achieving the effect of suture-free anastomosis, saving time, and improving long-term efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

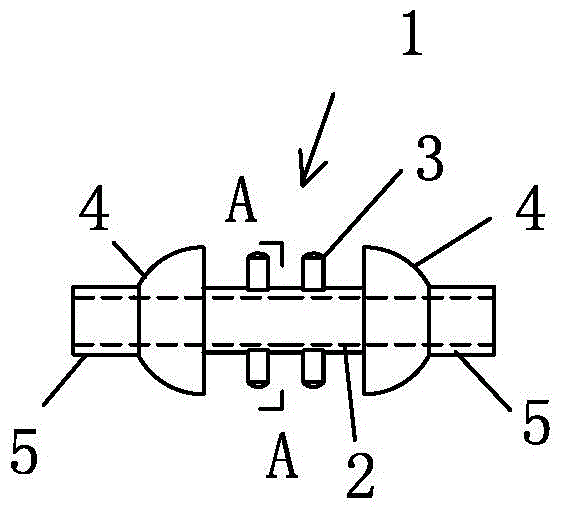

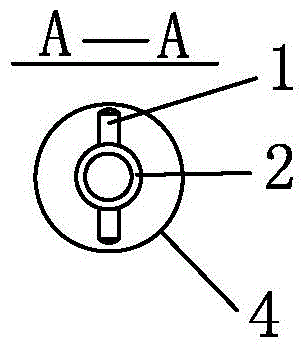

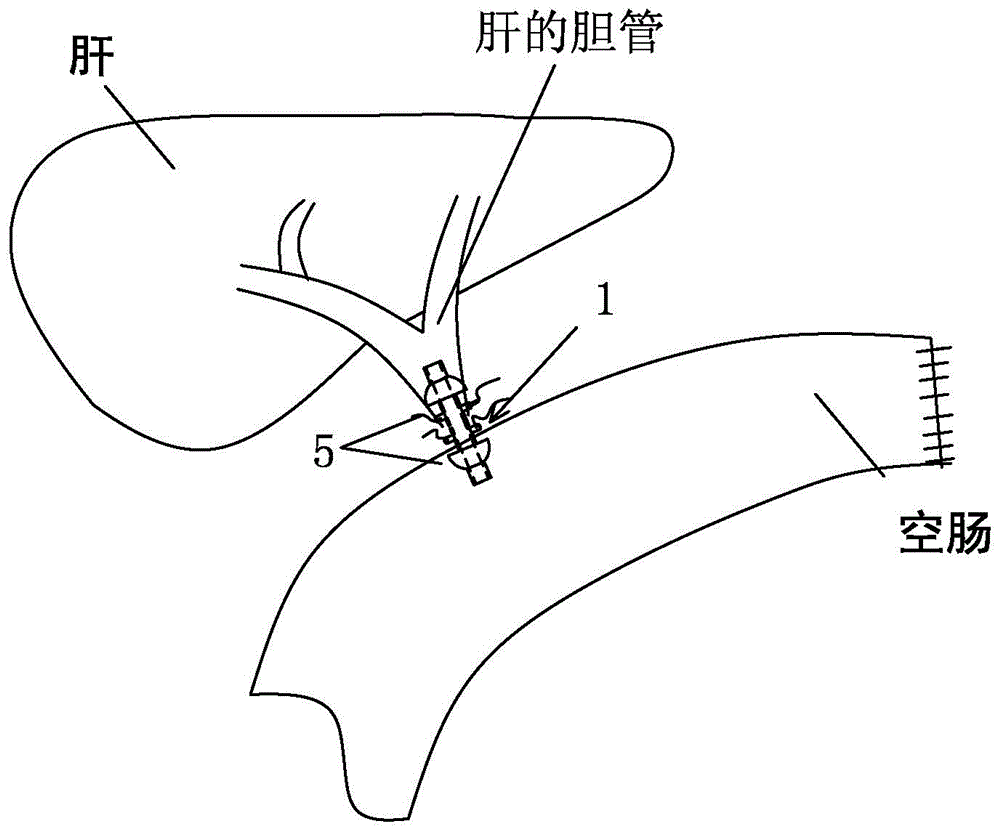

[0021] see figure 1 , figure 2 Shown: a 3D printing suture-free biliary-enteric anastomosis stent, the biliary-intestinal anastomosis stent 1 includes a stent tube 2 and a protruding post 3 protruding from the outer wall of the stent tube, and a convex head is integrally connected to both ends of the stent tube 1 4. A drainage tube 5 is connected to the outer end of the protruding head 4, and the biliary-enteric anastomosis bracket 1 is made of degradable biomaterials by 3D printing technology.

[0022] Wherein, the protruding head 4 is in the shape of a hemisphere, and the arc faces to the outer sides of both ends.

[0023] Wherein, upper and lower protrusions 3 are respectively provided on the outer wall of the bracket tube 2 near the protrusions at both ends.

[0024] A method for preparing a suture-free biliary-enteric anastomosis bracket with 3D printing, comprising the following steps:

[0025] (1) Measure the diameter of the bile duct in patients who need hepatobili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com