Acid-base bifunctional catalyst used for catalytic synthesis of methyl acrylate and preparation method thereof

An acid-base dual function, methyl acrylate technology, which is applied in the preparation of organic compounds, catalyst activation/preparation, preparation of carboxylate and other directions, can solve the problems of complex preparation process and poor repeatability, and achieves simple preparation process and high response. Effects of selectivity and yield, good synergistic catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 0.34g of barium nitrate in deionized water to prepare 1mL of barium nitrate solution, weigh 1.0g of activated carbon, impregnate the activated carbon in the prepared barium nitrate solution, soak in a water bath for 3h, and dry at 120°C for 3h.

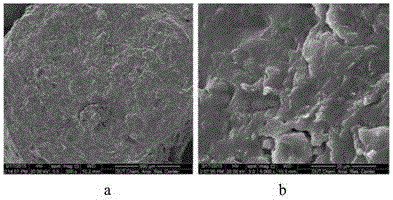

[0037] Weigh 4.0g of pseudo-boehmite and mix it with the loaded activated carbon, extrude into a strip, and dry a part of the shaped sample at 120°C for 3 hours to obtain BaO / Al without high-temperature calcination 2 o 3 catalyst, figure 2 uncalcined BaO / Al 2 o 3 From the electron microscope image, it can be seen that the surface is relatively smooth on the whole, and no loose porous structure appears; another part of the molded sample is calcined at a temperature of 550°C for 6 hours. Prepare the catalyst BaO / Al that is loaded with mass percent and is 7% (accounting for the mass percent of carrier) barium oxide 2 o 3 .

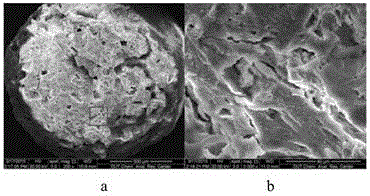

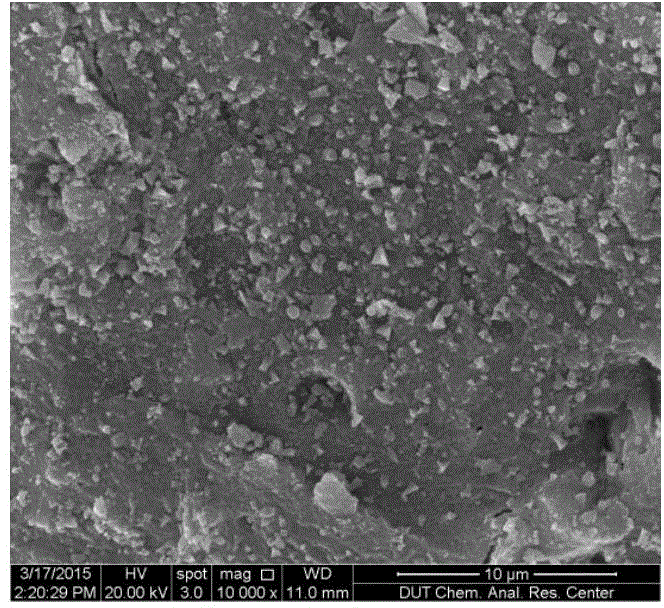

[0038] image 3 BaO / Al after calcination2 o 3 Electron micrographs show that after calcin...

Embodiment 2

[0043] Change barium nitrate into 0.46g cesium nitrate in embodiment 1, prepare the catalyst Cs that is loaded with 7% (accounting for the mass percent of carrier) cesium oxide with the preparation method of embodiment 1 2 O / Al 2 o 3 .

Embodiment 3

[0045] Change barium nitrate into 0.74g magnesium nitrate in embodiment 1, prepare the catalyst MgO / Al that is loaded with 7% (accounting for the mass percent of support) magnesium oxide with the preparation method of embodiment 1 2 o 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com