A feeding preparation system and method suitable for worm bioreactors

A bioreactor and material technology, which is applied in the field of feeding preparation system and worm bioreactor feeding preparation system, can solve the problem of mechanization, low level of automation, low standardization of feeding pretreatment, and restrictions on worm bioreactor processing Efficiency and economic benefits and other issues, to achieve the effect of improving efficiency and economic benefits, excellent quality, and improved standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

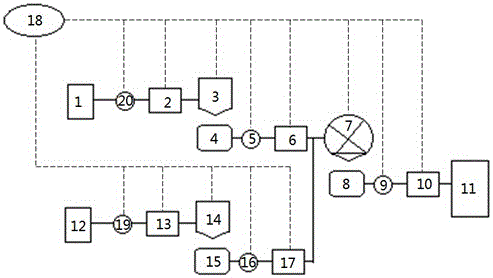

[0023] The present invention will be further described below with reference to the accompanying drawings.

[0024] refer to figure 1, the feeding preparation system suitable for the worm bioreactor of the present invention includes an automatic controller 18, a main water line and several auxiliary water lines. 20. The first material conveyor 2 and the first organic waste sorting and crushing machine 3, the sequentially connected raw material conditioning tank 4, the second flow meter 5, the second material conveyor 6 and the mixer 7, and the sequentially connected feed storage The tank 8, the third flow meter 9, the third material conveyor 10 and the feeding and distributing machine 11, the raw material conditioning tank 4 is located below the discharge port of the first organic waste sorting and crushing machine 3, and the feeding storage tank 8 is located in the mixer 7 below the discharge port; each of the auxiliary lines includes an initial auxiliary material collection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com