Composite material tamping tine and preparation method thereof

A composite material and composite material layer technology, which is applied in the field of composite material stamping and its preparation, can solve problems such as defects in the bonding surface, affecting metal bonding, and poor temperature control, achieving good interface bonding, prolonging service life, and moisturizing good moisture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

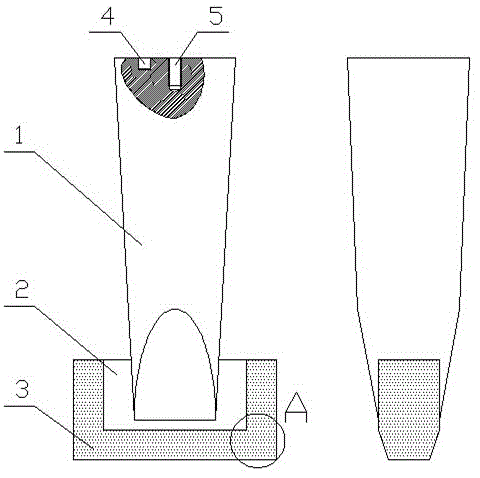

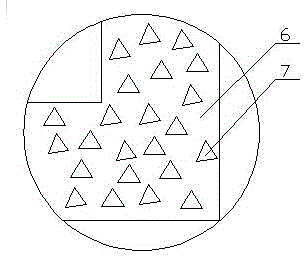

[0030] Such as Figures 1 to 4 As shown, the composite material tamping pick includes a pick body 1 and a pick palm 2, and a layer of ceramic particle-reinforced metal matrix composite material layer 3 is wrapped on the surface of the pick palm 3, and the thickness of the ceramic particle-reinforced metal matrix composite material layer 3 is It is 10mm, and the ceramic particles are WC, and the particle size is 150μm. The volume fraction of ceramic particles in the ceramic particle reinforced metal matrix composite material is 50%, and the rest of the matrix is the same as the material of the pick body, which is high chromium cast iron.

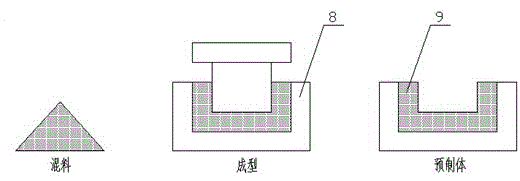

[0031] The preparation method of the composite material stamp pick described in the present embodiment, as image 3 , 4 As shown, the specific steps are as follows:

[0032] (1) A mixed solution of WC particles with a particle size of 150 μm, water glass solution and polyvinyl alcohol solution (the content of the mixed solution is 3% of t...

Embodiment 2

[0037] Such as Figures 1 to 4 As shown, a layer of ceramic particle reinforced metal matrix composite material is wrapped on the surface of the palm of the composite material tamping pick. The thickness of the composite layer is 15mm, and the ceramic particle is B 4 C, the particle size is 380 μm, the volume fraction of ceramic particles in the ceramic particle reinforced metal matrix composite material is 55%, and the remaining matrix is the same as the material of the pick body, which is 40Cr.

[0038] The preparation method of the composite material stamp pick described in the present embodiment, as image 3 , 4 As shown, the specific steps are as follows:

[0039] (1) B with a particle size of 380 μm 4 C particles and aluminum phosphate solution (content is 4% of the mass fraction of ceramic particles) are put into a ball mill tank, uniformly mixed on the ball mill for 60min, and then the uniformly mixed particles are filled into the prefabricated body mold 8. 2 Cal...

Embodiment 3

[0044] Such as Figures 1 to 4 As shown, a layer of ceramic particle reinforced metal matrix composite material is wrapped on the surface of the palm of the composite ramming pick. The thickness of the composite layer is 9mm, and the ceramic particles are Cr 3 C 2 , the particle size is 120μm, the volume fraction of ceramic particles in the ceramic particle reinforced metal matrix composite is 45%, and the rest of the matrix is the same as the material of the pick body, which is 40CrNiMo.

[0045] The preparation method of the composite material stamp pick described in the present embodiment, as image 3 , 4 As shown, the specific steps are as follows:

[0046] (1) Cr with a particle size of 120 μm 3 C 2 The particles and the aluminum dihydrogen phosphate solution (the content is 3.5% of the mass fraction of the ceramic particles) are put into a ball mill tank, uniformly mixed on the ball mill for 90 minutes, and then the uniformly mixed particles are filled into the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com