High-temperature-resistant composite material with nuclear radiation shielding effect

A composite material and shielding effect technology, applied in the field of nuclear radiation shielding materials, can solve problems such as poor movement and radiation resistance, poor comprehensive shielding effect, and difficulty in satisfying toughness, etc., to achieve poor radiation resistance, comprehensive Good shielding effect, solve the effect that is difficult to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

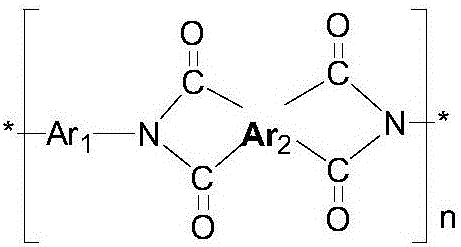

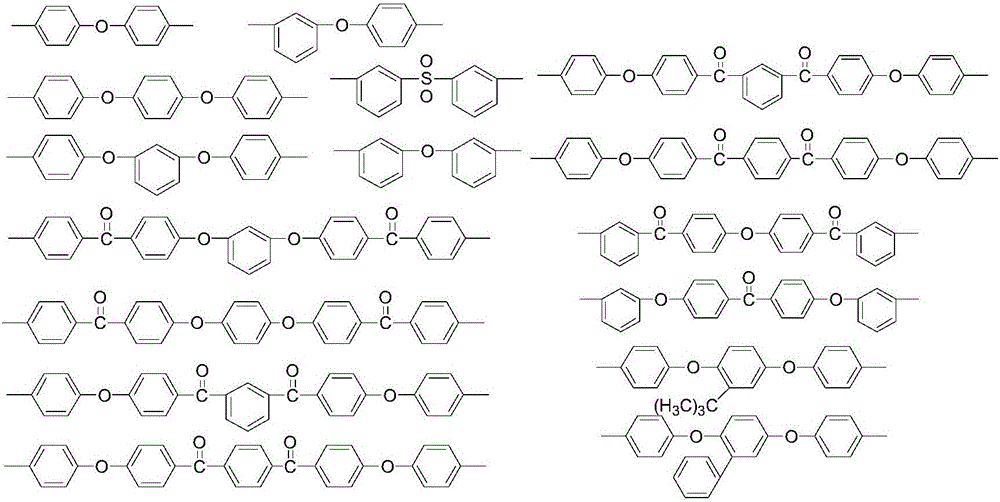

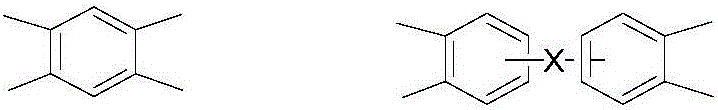

Method used

Image

Examples

Embodiment 1

[0021] A high-temperature-resistant composite material with nuclear radiation shielding effect, which is composed of the following materials in parts by weight: 50 parts of thermoplastic polyimide matrix, 15 parts of chopped carbon fiber, 10 parts of boron carbide, and 20 parts of lead powder , 1 part of silane coupling agent KH550, 2 parts of antioxidant, and 2 parts of flow promoter; said antioxidant is 2,6-tertiary butyl-4-methylphenol and didodecyl alcohol The weight ratio of ester, 2,6-tertiary butyl-4-methylphenol and didodecyl alcohol ester is 1:1, and the flow accelerator is an acid anhydride accelerator.

[0022] A high-temperature-resistant composite material with nuclear radiation shielding effect, the preparation process is as follows: first, carbon fiber, boron carbide and lead powder are soaked in a silane coupling agent for treatment, and the treatment time is 6 hours. After the treatment, the mixture A is obtained. Dry the mixture A in a drying oven at a drying...

Embodiment 2

[0024] A high-temperature-resistant composite material with nuclear radiation shielding effect, which is composed of the following materials in parts by weight: 70 parts of thermoplastic polyimide matrix, 5 parts of chopped carbon fiber, 2 parts of boron carbide, and 20 parts of lead powder , 1 part of silane coupling agent KH550, 1 part of antioxidant, 1 part of flow promoter, said antioxidant is 2,6-tertiary butyl-4-methylphenol and didodecyl alcohol Ester, the weight ratio of 2,6-tertiary butyl-4-methylphenol and didodecyl alcohol ester is 1:1, and described flow enhancer is an acid anhydride accelerator; Its preparation process is identical with embodiment 1, Obtain high temperature resistant composite material b.

Embodiment 3

[0026] A high-temperature-resistant composite material with nuclear radiation shielding effect, which is composed of the following materials in parts by weight: 80 parts of thermoplastic polyimide matrix, 10 parts of chopped carbon fiber, 5 parts of boron carbide, and 5 parts of lead carbonate , lead oxide is 5 parts, silane coupling agent KH550 is 3 parts, antioxidant is 1 part, flow promoter is 1 part, and the antioxidant is 2,6-tertiary butyl-4-methylphenol And two dodecyl alcohol esters, the weight ratio of 2,6-tertiary butyl-4-methylphenol and double dodecyl alcohol esters is 1:1, and the flow accelerator is an acid anhydride accelerator; its preparation process Same as in Example 1, a high temperature resistant composite material c was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com