Polycrystalline silicon production method and device by pyrogenation of silane

A production device and technology for polysilicon, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of dust control, high energy consumption of polysilicon, and achieve the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

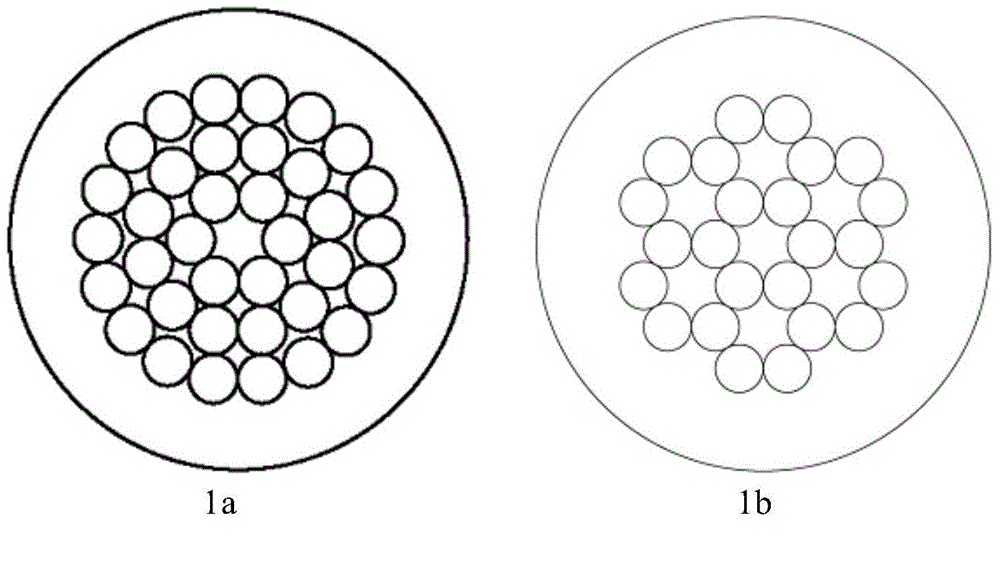

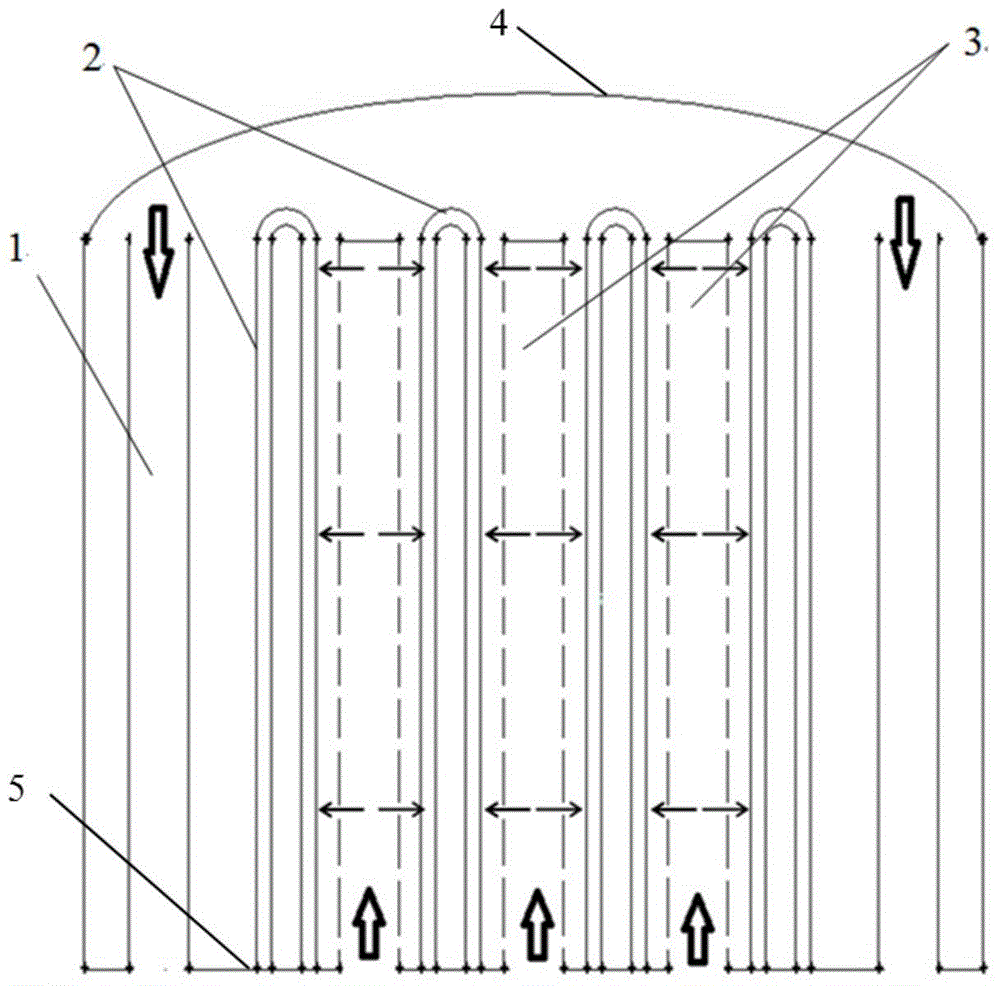

[0035] Example 1: A small bell jar reactor with 12 pairs of silicon rods, the center distance of the silicon rods is 180mm, the height of the silicon rods is 1200mm, the diameter of the guide tube is 160mm, and the height of the guide tube is 1000mm. The arrangement of the silicon rods and the guide tube is as follows image 3 As shown, six rectangular slit nozzles are opened on the side walls of the seven guide tubes in the central area, respectively facing the six silicon rods around them, and three slit nozzles are opened on the side walls of the three inlet guide tubes on the edge, facing respectively There are three silicon rods around, and three circular outlet guide tubes are evenly distributed on the edge. The slit nozzle width on the side wall of the inlet guide tube is 0.1mm, corresponding to the feed gas nozzle velocity of 2.8m / s.

[0036] The molar concentration of silane in the feed gas at a temperature of 350K is 2%, the emissivity of the outer surface of the poli...

Embodiment 2

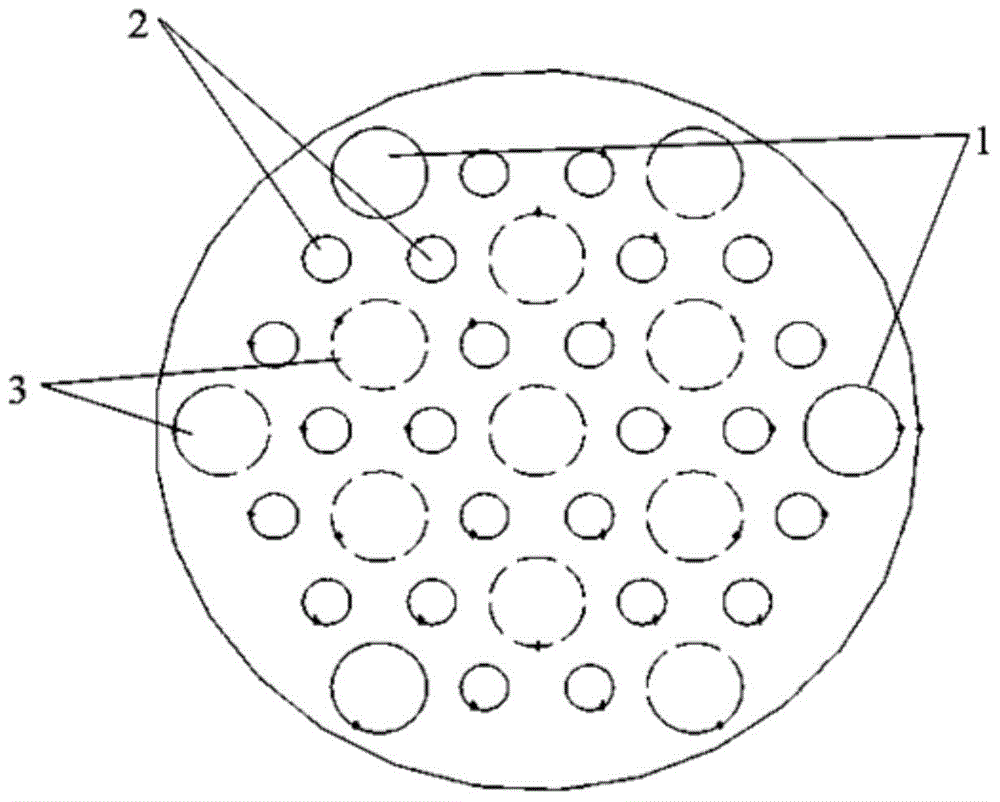

[0037] Example 2: a medium-sized bell jar reactor with 30 pairs of silicon rods, the center distance of the silicon rods is 220mm, the height of the silicon rods is 2100mm, the diameter of the guide tube is 220mm, and the height of the guide tube is 2000mm. The arrangement of the silicon rods and the guide tube is as follows Figure 5 As shown, six rows of nozzles are opened on the side walls of the nineteen air guide tubes in the central area, respectively facing the six silicon rods around them, and four rows of nozzles are opened on the side walls of the twelve inlet guide tubes on the edge, facing the four surrounding silicon rods respectively. Silicon rods, six rectangular outlet guide tubes are evenly distributed on the edge, and each row of nozzles on the side wall of the inlet guide tube contains 10 uniformly distributed nozzle holes with a diameter of 1mm, corresponding to the feed gas nozzle velocity of 25.2m / s.

[0038]The molar concentration of silane in the feed ga...

Embodiment 3

[0039] Embodiment 3: a medium-sized bell jar reactor with 30 pairs of silicon rods, the arrangement of the silicon rods and the guide cylinder is referred to in Example 2, the difference is that the bell jar has an exhaust port, and the reaction tail gas is discharged from the top of the bell jar reactor. Each row of nozzles on the side wall of the air intake guide tube contains 20 circular nozzle holes with a diameter of 0.5-1.5 mm that gradually decrease from bottom to top, corresponding to the feed gas nozzle velocity of 15.8m / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com