Method for preparing hydrogenated C9 petroleum resin

A technology for petroleum resin and resin, applied in the field of preparing hydrogenated C9 petroleum resin, can solve the problems of poor economic benefit and low product grade, and achieve the effects of improved catalyst life, wide range of raw materials and less reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

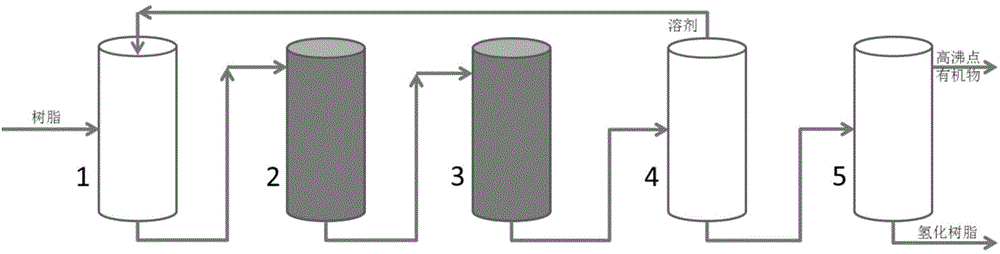

Method used

Image

Examples

Embodiment 1

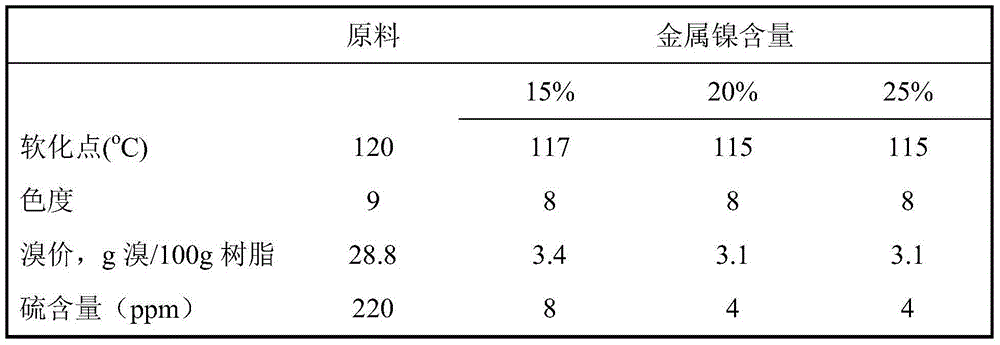

[0023] Example 1: Using zinc nitrate and nickel nitrate as precursors, NiO / ZnO with different Ni loadings was prepared by co-precipitation method, and NiO / ZnO was reduced at 350°C for 2 hours to prepare Ni / ZnO catalysts. See Table 1 below for the properties of raw materials and the effects of hydrogenation adsorption desulfurization with different Ni loadings. The reaction conditions are feed temperature 260°C, hydrogen partial pressure 1MPa, volume space velocity 6h -1 , The volume ratio of hydrogen to oil is 200:1, and the resin concentration is 20%. See the following table 1 for resin raw materials and resin properties after hydrogenation adsorption desulfurization.

[0024]

[0025] ① Chromaticity measurement is to compare the color of the resin with 50wt% toluene solution and the standard Fe-Co colorimetric solution.

[0026] It can be seen from Table 1 that when Ni / ZnO is used as the hydrogenation adsorption desulfurization catalyst, the desulfurization effect is obv...

Embodiment 2

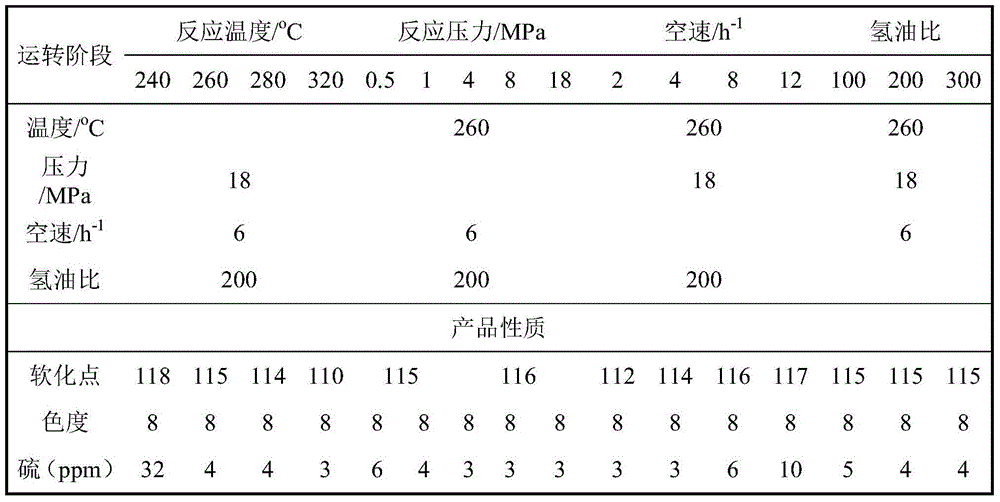

[0027] Example 2: Using Ni / ZnO with 20% Ni loading as the hydrogenation adsorption desulfurization catalyst, the influence of reaction conditions on the desulfurization effect was investigated. See Table 2 below for resin properties after desulfurization.

[0028]

Embodiment 3

[0029] Example 3: Using Ni / ZnO with 20% Ni loading as the hydrogenation adsorption desulfurization catalyst, the reaction conditions are feed temperature 260°C, hydrogen partial pressure 1MPa, volume space velocity 6h -1 , The volume ratio of hydrogen to oil is 200:1, and the resin concentration is 20%. See Table 3 below for the product properties obtained after 100 hours of operation.

[0030]

[0031] It can be seen from Table 3 that the 100-hour experimental results show that the sulfur and bromine values on the Ni / ZnO reactive adsorption desulfurization catalyst are basically unchanged compared with the initial test, indicating that this technology has good stability. After running for a long time, the sulfur adsorption capacity of the catalyst reaches 20% of the weight of the catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com