A method and device for pyrolysis and carbonization of organic waste

A technology of pyrolysis carbonization and treatment method, applied in the field of organic waste resource utilization, can solve the problems of high production cost, low heat utilization rate, low calorific value, etc., to prevent pipeline blockage, ensure normal work, and reduce equipment failures The effect of incidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Figure 5 It is a process flow chart of the pyrolysis carbonization treatment method of organic waste in Embodiment 1. Such as Figure 5 As shown, a pyrolysis carbonization treatment method for organic waste, including heat supply, pre-treatment, carbonization treatment, gas treatment and gas utilization,

[0055] (a) Heating part: a burner is set, and the flame port of the burner is passed into a combustion chamber to obtain high-temperature flue gas;

[0056] (b) Pre-treatment part: put the organic waste into the pre-treatment chamber, and the high-temperature flue gas introduced into the heating part is heated by an external heating jacket to heat the organic waste in the pre-treatment chamber. The temperature is 500-700°C, and the pre-treatment room is heated to 100-250°C;

[0057] (c) Carbonization treatment part: Send the pre-treated organic waste into the carbonization treatment chamber, introduce the high-temperature flue gas from the heating part, and use th...

Embodiment 2

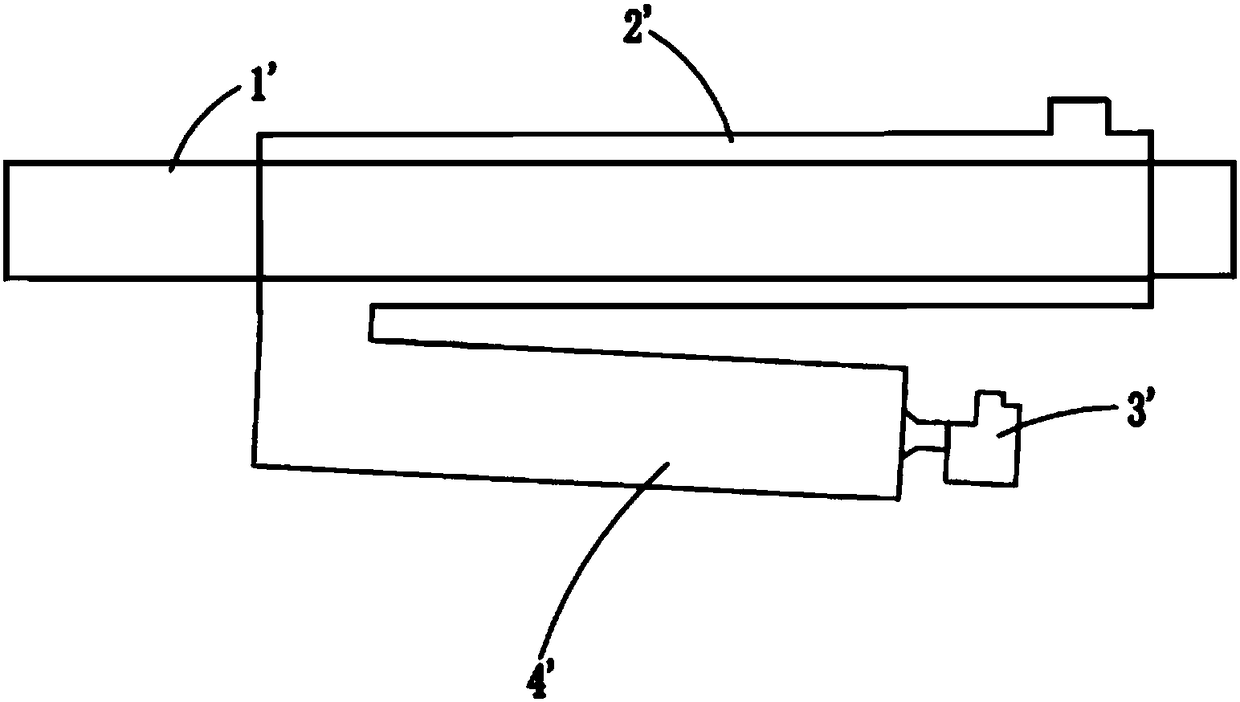

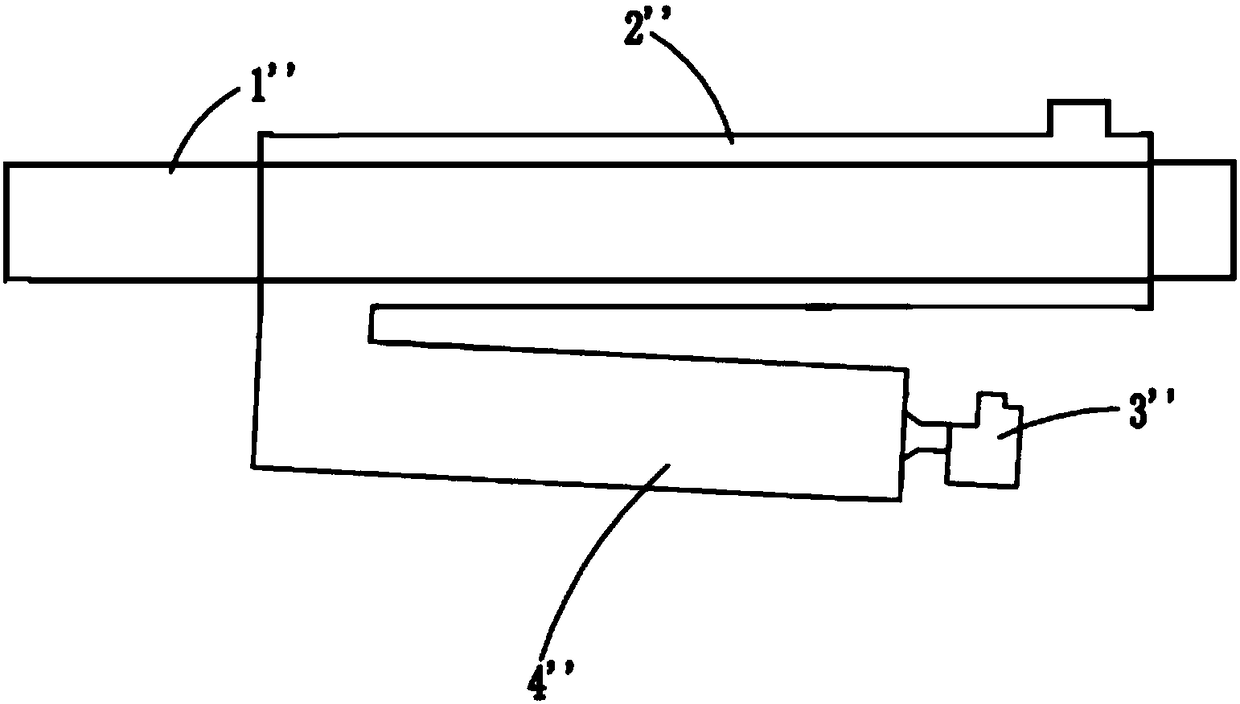

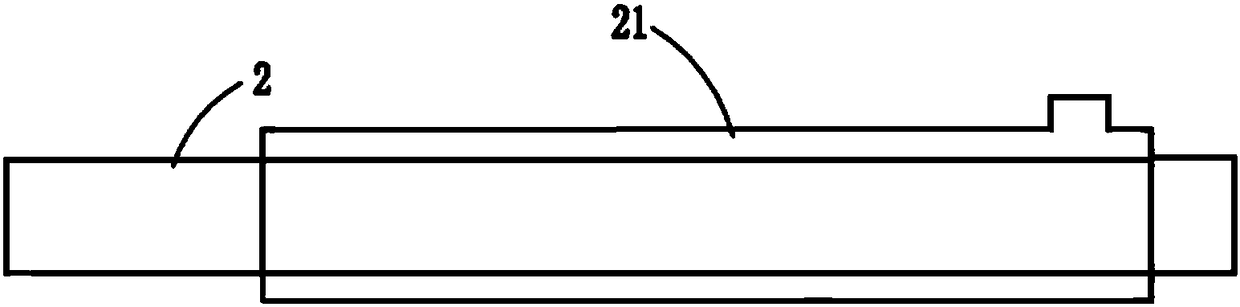

[0065] Figure 6 It is a schematic diagram of the overall structure of the organic waste pyrolysis carbonization treatment device in Embodiment 2. Such as Figure 6 As shown, a pyrolysis carbonization treatment device for organic waste includes a combustion chamber 1, a pre-treatment unit, a carbonization treatment unit, a gas treatment unit and a gas utilization unit, and the combustion chamber 1 is provided with a burner 1a; as image 3 As shown, the pre-processing unit is an external heat dryer 2, the dryer 2 is provided with a dryer jacket 21, and the dryer jacket 21 passes through the flue gas delivery pipeline 4 and the high-temperature flue gas outlet of the combustion chamber 1 1a is the same; if Figure 4 As shown, the carbonization treatment unit is an external heating type carbonization furnace 3, the carbonization furnace 3 is provided with a carbonization furnace jacket 31, and the carbonization furnace jacket 31 passes through the flue gas delivery pipeline 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com