Electrical steel plasma stable suspension device and preparation method thereof

A suspension device, electrical steel technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as surface damage of annealed steel strips, achieve high grades, reduce damage or nodules, and excellent surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

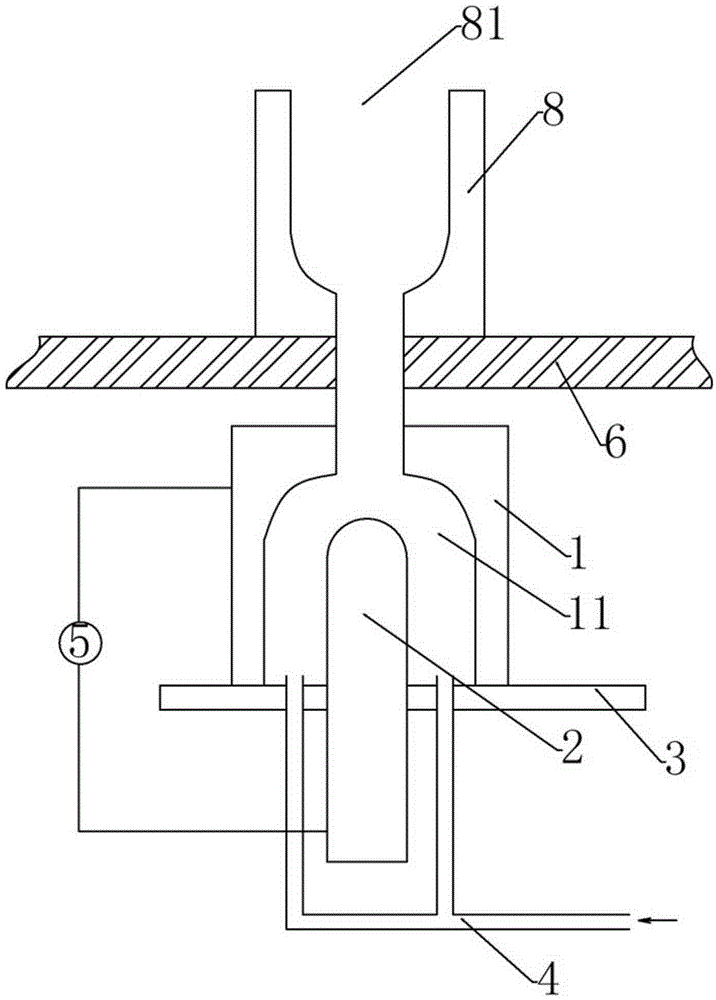

[0037] see figure 1 , an electrical steel plasma stabilized suspension device, has:

[0038] Airflow slowing device, which is connected on the furnace floor 6 in the furnace, the upper end surface of the airflow slowing device is provided with a gas outlet, and the upper end surface is used as a supporting surface for electrical steel;

[0039] The plasma cabinet 1 has a cavity 11 inside, and the plasma cabinet 1 is provided with an opening communicating with the cavity 11, and the opening communicates with the airflow slowing device;

[0040] Electrode rod 2, which extends into the cavity 11 of the plasma cabinet 1;

[0041] The power supply device includes a power supply 5, the power supply 5 connects the electrode rod 2 and the plasma cabinet 1 through a circuit, the plasma cabinet 1 is made of conductive material, and the electrode rod 2 and the plasma cabinet 1 form a discharge electrode;

[0042] Air intake device, which feeds gas into the cavity 11 of the plasma cabin...

Embodiment 2

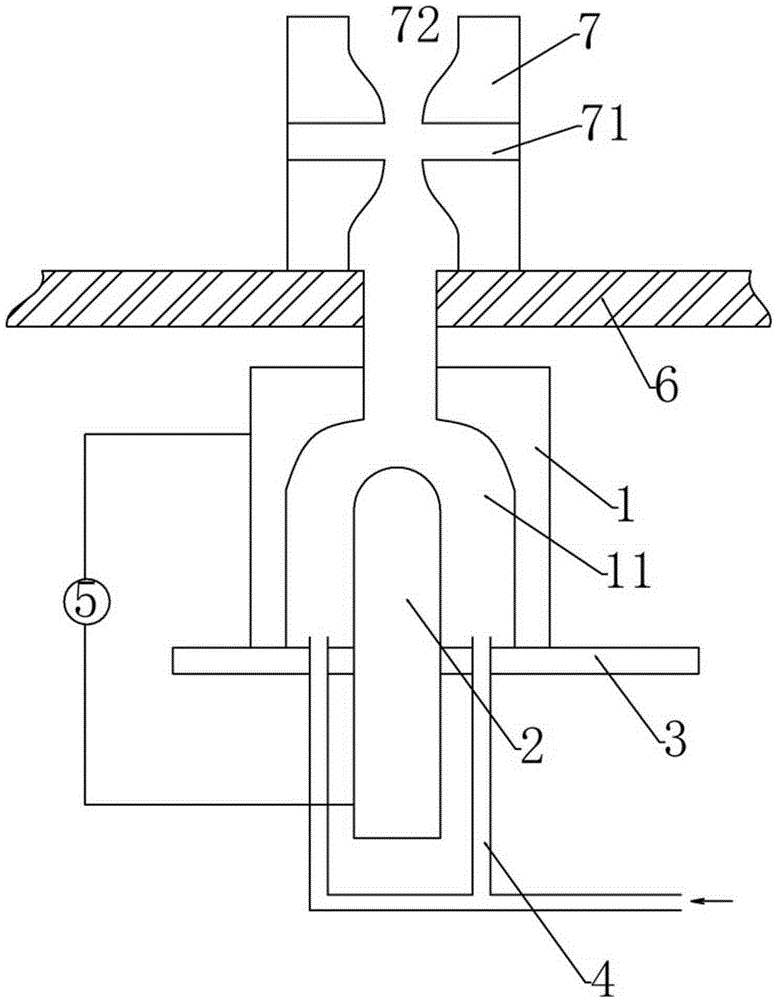

[0054] see figure 2 , an electrical steel plasma stabilized suspension device,

[0055]1. The high-temperature plasma suspension device is divided into two parts, with the bottom of the annealing furnace as the dividing line: 1) the plasma generating device located outside the furnace; 2) the airflow slowing device that supports the steel strip in the furnace, located inside the furnace, The middle part of the lower part of the steel strip.

[0056] 2. The gas enters from the gas inlet, where the gas can be hydrogen, nitrogen, argon, etc. The plasma is connected to an external power source 5 by means of the electrodes, and the power source 5 powers the arc discharge of a pair of electrodes forming the plasma and the electrode rod 2 inside. The arc discharge makes the temperature of the gas rise rapidly and the volume expands hugely, forming a high-speed airflow into the airflow slowing device of the second part. Most of the plasma forming body is electrically insulating, a...

Embodiment 3

[0060] A method for manufacturing the above-mentioned electrical steel plasma stabilized suspension device, comprising the following steps:

[0061] 1) Punch a hole in furnace bottom plate 6;

[0062] 2) The airflow slowing device is installed on the furnace inner side of the furnace bottom plate 6, and the airflow slowing device corresponds to the position of the hole on the furnace bottom plate 6;

[0063] 3) connecting the opening of the plasma with the hole of the furnace floor 6;

[0064] 4) The electrode rod 2 extends into the cavity 11 through the plasma;

[0065] 5) Connect the power supply 5 to the plasma cabinet and the electrode rod 2 through wires.

[0066] The purpose of this device is to form a large gas flow to form a sufficient supporting force for the steel strip, and the range of gas temperature increase is not the primary consideration. Therefore, the diameter of the electrode rod 2 is large, the area of the electrode rod 2 to the upper cavity 11 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com