Variable-focus optical lens system and preparation thereof

An optical lens, a variable technology, applied in the fields of electromechanical and soft machines, optics, and materials, it can solve problems such as difficult to obtain industrial applications, not found, etc., to achieve the effect of light weight, fast response, and avoidance of gravity distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

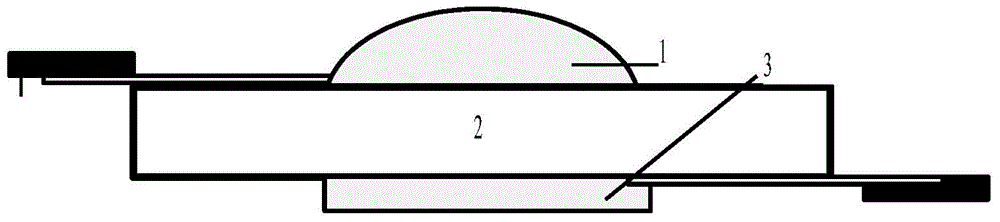

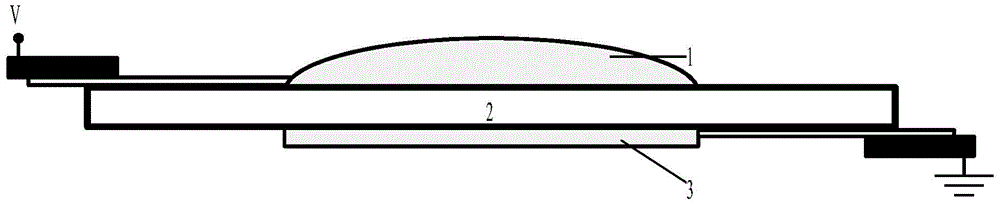

Image

Examples

Embodiment 1

[0037] Step 1, adding polymer monomer acrylamide (AAm) into deionized water, fully stirring and dissolving, and preparing a polymer monomer solution with a mass fraction of 1%;

[0038] Step 2, adding metal salt sodium chloride (LiCl) with a concentration of 0.5 mol / L relative to the solvent into the polymer monomer solution, and adding a crosslinking agent N, N- Methylenebisacrylamide, thermal initiator ammonium persulfate with a molecular weight of 228.201g / mol, catalyst N,N,N',N'-tetramethylethylenediamine with a molecular weight of 116.20g / mol, mixed well to obtain a mixed liquid. The mass fraction of the crosslinking agent relative to the macromolecular monomer is 0.001%, the mass fraction of the thermal initiator relative to the macromolecular monomer is 0.001%, and the volume fraction of the catalyst relative to the solvent is 0.001%.

[0039] Step 3: Pour the above mixed solution into spherical segment-shaped glass or plexiglass molds and glass plate or plexiglass pla...

Embodiment 2

[0044] In step 1, 1-butyl-3-methylimidazolium methyl sulfate is selected as the ionic liquid, and 4-15 wt% of hydroxyethyl methacrylate relative to the ionic liquid is added to the ionic liquid.

[0045] Step 2, continue to add 3-5wt% polyethylene glycol dimethacrylate relative to hydroxyethyl methacrylate monomer and 1-2wt% 2-hydroxyl-2 - methylpropiophenone, and stir to mix well.

[0046] Step 3: Pour the above-mentioned mixed solution into a spherical-segment-shaped glass or plexiglass mold and a glass plate or plexiglass plate mold with a silica gel gasket, and place it in an ultraviolet crosslinking instrument for 3 hours to prepare a product with specific Shaped conductive ion gel, the modulus of the ionic liquid gel prepared in this example is 2.0-8.0kPa, and the strain can reach 4-10 times.

[0047] In step 4, the dielectric elastomer film PDMS is biaxially pre-stretched and fixed around it.

[0048] Step 5, aligning and pasting the spherical segment-shaped and sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com