a ta 3 no 5 /c composite fiber photocatalyst and preparation method thereof

A composite fiber and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost of graphene, complicated technical operation, etc., and achieve easy recycling and reliable test conditions Controlling and improving photocatalytic activity and stabilizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A Ta 3 N 5 The preparation method of / C heterojunction fiber photocatalyst comprises the following steps:

[0037] Step 1, prepare Ta 3 N 5 Spinning liquid: add soluble tantalum salt into the polymer solution and stir for 2-12 hours to obtain Ta 3 N 5 spinning solution.

[0038] The polymer solution contains polyvinylpyrrolidone (PVP), absolute ethanol, N,N-dimethylformamide, and acetic acid, wherein the volume of the absolute ethanol, N,N-dimethylformamide, and acetic acid The ratio is (3-4): 1:1 (for example, it can also be any ratio in 3.2:1:1, 3.5:1:1, 3.8:1:1, 4:1:1, preferably 3 :1:1); The molecular weight of this PVP is 1300000;

[0039] The Ta 3 N 5 In the spinning solution, the mass percentage concentration of the PVP is 5-10wt% (for example, it can be any value in 5wt%, 6wt%, 8wt%, 10wt%, etc. or any range between the two), the soluble The mass percent concentration of the tantalum salt is 5-15wt% (for example, it can be any value in 5wt%, 8wt%, 10wt...

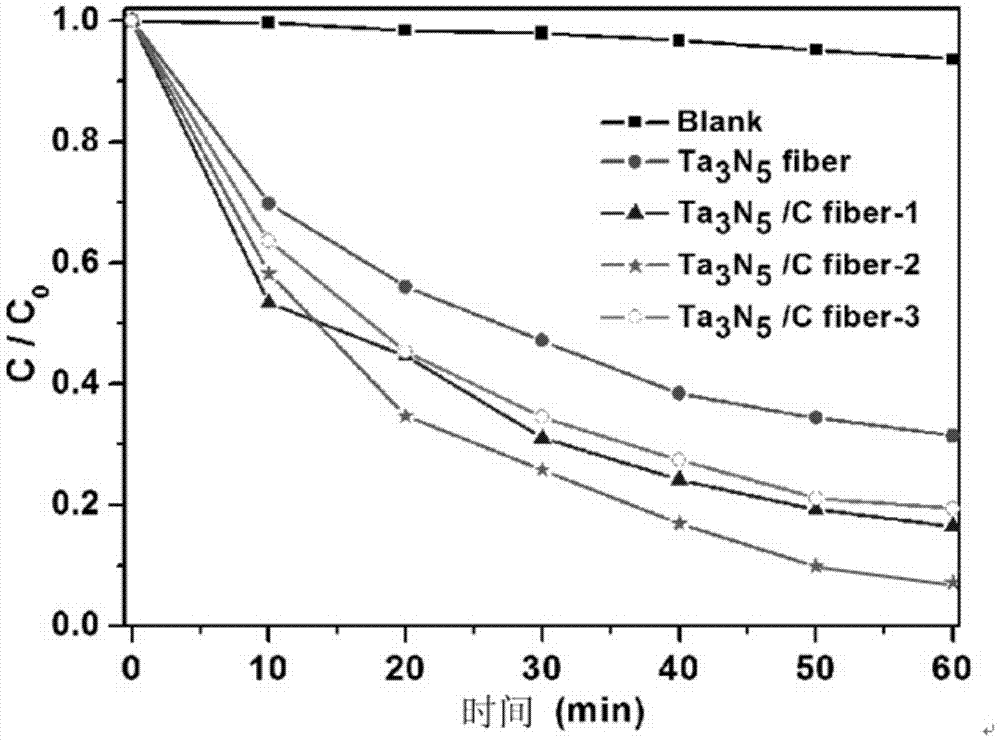

Embodiment 1

[0057] (1) Preparation of Ta 3 N 5 Spinning solution: Add tantalum ethoxide into the polymer solution, and stir for 8 hours to obtain Ta 3 N 5 spinning solution.

[0058] The polymer solution is formed by mixing polyvinylpyrrolidone (PVP), absolute ethanol, N,N-dimethylformamide, and acetic acid, wherein the absolute ethanol, N,N-dimethylformamide and The volume ratio of acetic acid is 3: 1: 1; the molecular weight of the PVP is 1300000;

[0059] The Ta 3 N 5 In the spinning solution, the mass percent concentration of the PVP is 10wt%, and the mass percent concentration of the soluble tantalum salt is 10wt%.

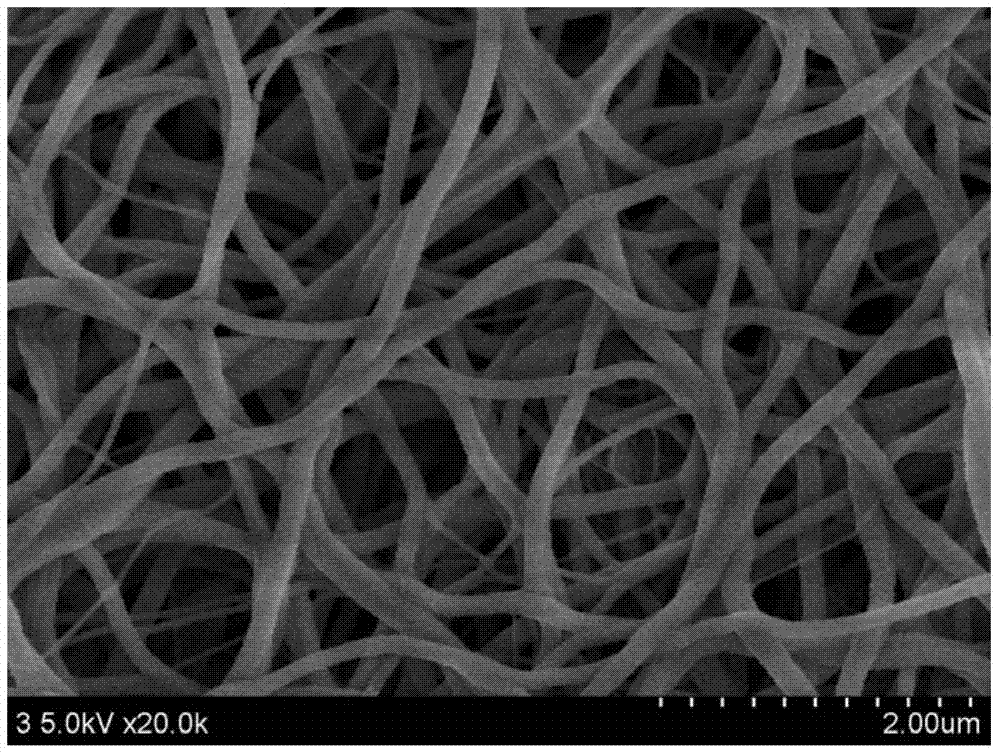

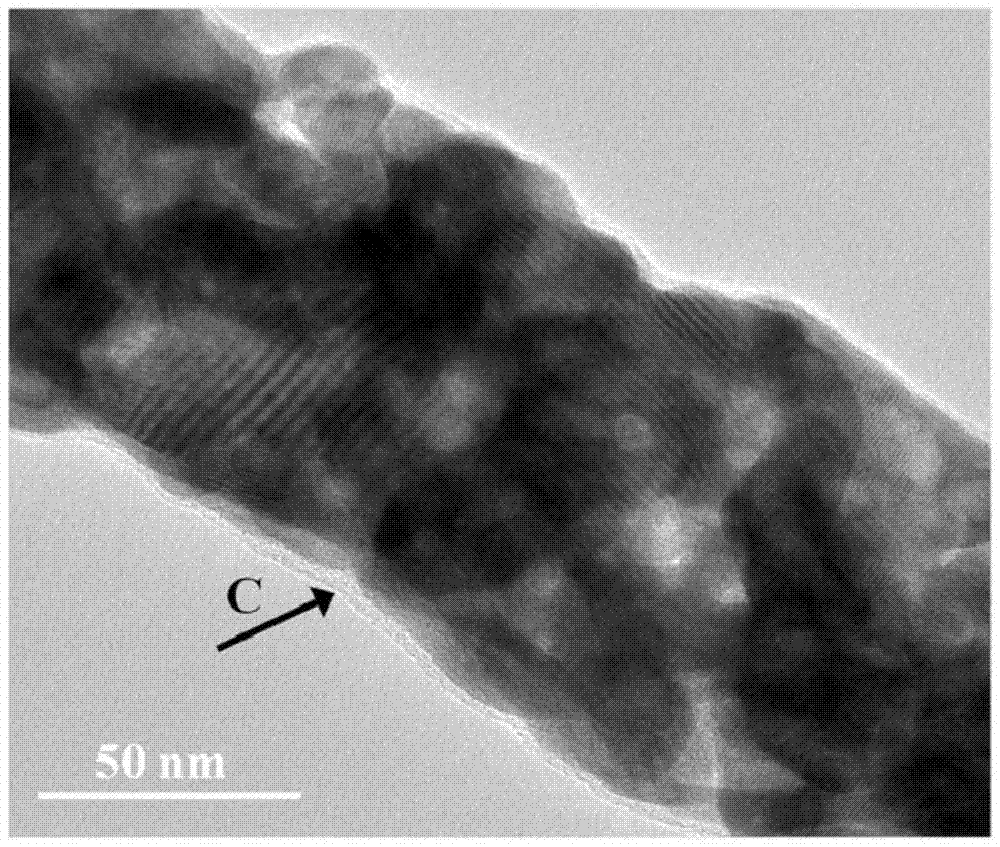

[0060] (2) Preparation of Ta 2 o 5 Fiber: the Ta3N5 spinning liquid is subjected to electrospinning treatment, the conditions are: working voltage (direct current) 12kV, working distance (i.e. the distance between the nozzle tip and the receiver) 20cm, the propulsion speed of the spinning solution (i.e. the propulsion of the propeller) Speed) is: 0.5mL / h, and th...

Embodiment 2

[0069] (1) Preparation of Ta 3 N 5 Spinning solution: Add tantalum ethoxide into the polymer solution and stir for 2-12 hours to obtain Ta 3 N 5 spinning solution.

[0070] The polymer solution is made by mixing polyvinylpyrrolidone (PVP), absolute ethanol, N,N-dimethylformamide, and acetic acid, wherein the absolute ethanol, N,N-dimethylformamide, and acetic acid The volume ratio is 3:1:1; the molecular weight of the PVP is 1300000;

[0071] The Ta 3 N 5 In the spinning solution, the mass percent concentration of the PVP is 10wt%, and the mass percent concentration of the soluble tantalum salt is 10wt%.

[0072] (2) Preparation of Ta 2 o 5 Fiber: the Ta 3 N 5 The spinning solution is subjected to electrospinning treatment, the conditions are: working voltage (direct current) 12kV, working distance (that is, the distance between the tip of the nozzle and the receiver) 20cm, and the advancing speed of the spinning solution (that is, the advancing speed of the propelle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com