Ultralight ceramsite prepared by totally taking solid waste as raw material

A technology of solid waste and ultra-light pottery, which is applied in the production of clay products, ceramic products, ceramic materials, etc., can solve problems such as occupying a large area, pollute the environment, and hidden safety hazards, and achieve low production costs, simple production processes, and market competition. powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further describe the present invention, a kind of ultra-light ceramsite prepared from solid waste as raw material of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

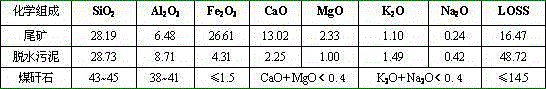

[0036] Table 1 is a table of the chemical composition of raw materials used in an ultra-light ceramsite prepared entirely from solid waste in the present invention.

[0037] Table 1 Chemical composition of raw materials used (%)

[0038]

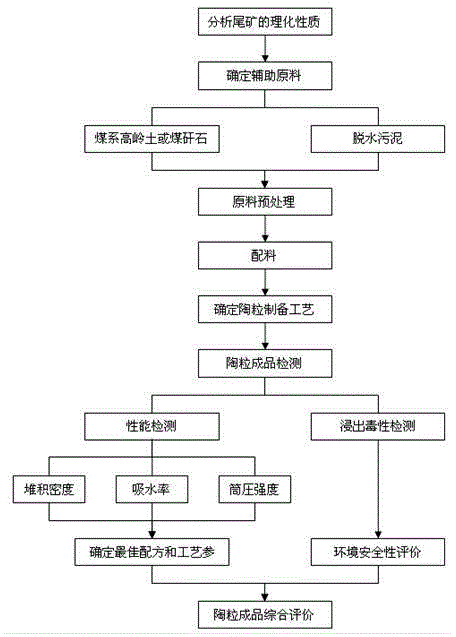

[0039] Depend on figure 1 It can be seen from the technical roadmap adopted by a kind of ultra-light ceramsite prepared from solid waste as raw material of the present invention shown that the process and parameters adopted by a kind of ultra-light ceramsite prepared from solid waste as raw material of the present invention are:

[0040] (1) Raw material selection

[0041] When firing ultra-light ceramsite, the chemical composition range of raw materials is generally: SiO 2 48~65%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com