A kind of method for preparing isocyanate by reactive distillation

A technology of isocyanate and reactive distillation, which is applied in the preparation of isocyanate derivatives, purification/separation of isocyanate derivatives, chemical instruments and methods, etc., can solve the problems of large heat load and waste of phosgene, and reduce heat load, energy saving, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

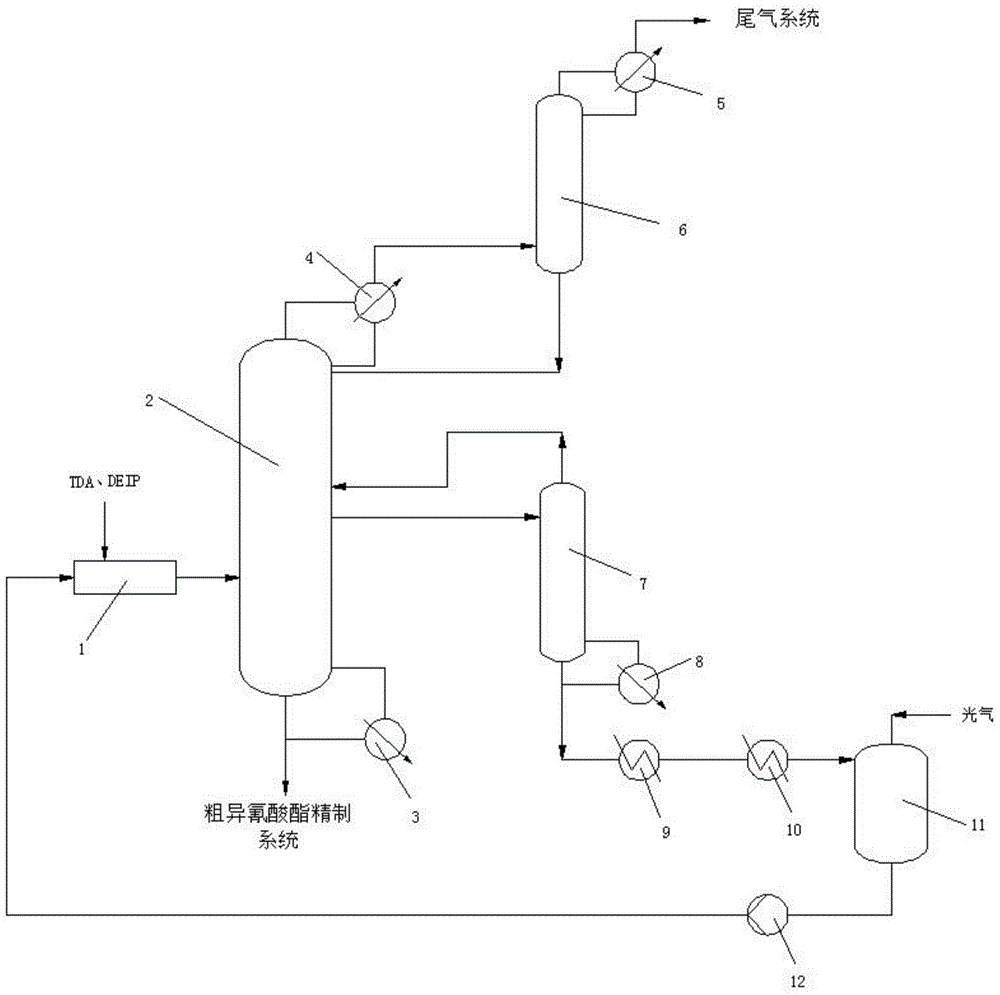

Embodiment 1

[0016] In the phosgene purification tower overhead gas system of the present embodiment, the exhaust gas system directly removes 4934 kg of toluenediamine with a temperature of 100 ° C and a pressure of 22 bar in 14253 kg of DEIP (diethyl isophthalate) with a temperature of 90 ° C. Toluene diamine solution is formed; toluene diamine solution and 35115kg / h temperature is-10 ℃, the liquid phosgene of pressure is 22bar enters jet reactor 1 and carries out luminescence reaction to obtain luminescence material, and the temperature of luminescence material after reaction is 103°C, the pressure is 16bar; then transfer the luminescence material to the reactive distillation tower 2 to carry out the thermophotochemical reaction, the operating pressure of the reactive distillation tower 2 is 15.8bar, and the reactor of the reactive distillation tower 2 is formed by the reactive distillation tower The reboiler 2 is heated to 148°C, the thermal load of the reactor of the reactive distillati...

Embodiment 2

[0018]The phosgene refining tower and the reactive distillation tower in this embodiment form a coupling system, and 4934 kg of toluenediamine at a temperature of 100 °C and a pressure of 22 bar are dissolved in 14253 kg of DEIP (diethyl isophthalate) at a temperature of 90 °C , to form a toluene diamine solution; the toluene diamine solution and 35115 kg / h of liquid phosgene with a temperature of -10 ° C and a pressure of 22 bar enter the jet reactor 1 for a luminescence reaction to obtain a luminescence material, and the temperature of the luminescence material after the reaction The temperature is 103°C and the pressure is 16bar; then the luminescence material is transferred to the reactive distillation tower 2 for thermophotochemical reaction, the operating pressure of the reactive distillation tower 2 is 15.8bar, and the reactor of the reactive distillation tower 2 The tower reboiler 3 is heated to 148 ° C, the heat load of the tower kettle is 3352Kw, and the toluene diiso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com