Synthetic method for alcohol ether sulfate salt foaming agent

A technology of sulfate ester salt and synthesis method, which is applied in the direction of sulfate ester preparation, drilling composition, chemical instruments and methods, etc., can solve the problems of high equipment requirements, and achieve simple operation, better liquid carrying capacity, and foam stability better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

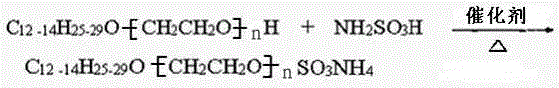

[0037] The synthetic method of alcohol ether sulfate ester foaming agent, comprises the following steps:

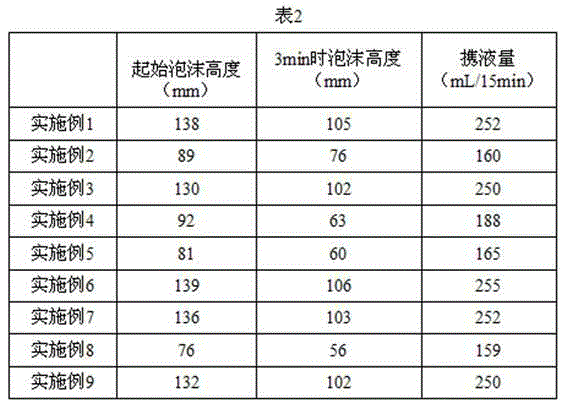

[0038] Take the same mass of MOA-5, and add the corresponding mass of sulfamic acid according to the molar ratio of fatty alcohol polyoxyethylene ether to sulfamic acid given in Table 1 below, and then add the total mass of reactants (that is, fatty alcohol polyoxyethylene The mass summation of vinyl ether and sulfamic acid) of 1wt% urea is used as a catalyst, reacts at the reaction temperature given in the following table 1, wherein, the reaction time is respectively the reaction time given in the following table 1, and alcohol ether sulfuric acid is obtained ester salt.

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com