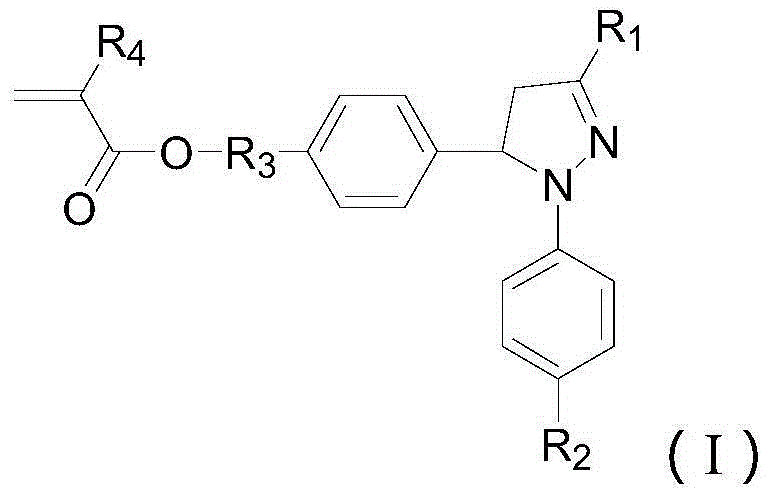

Alkenyl-containing pyrazoline sensitizer as well as preparation method and application thereof

A technology of alkenyl pyrazoline and sensitizer, applied to alkenyl pyrazoline-containing sensitizer and preparation thereof, the application field of the sensitizer in the field of photocuring can solve the problem of odor, Easy migration, unsatisfactory solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

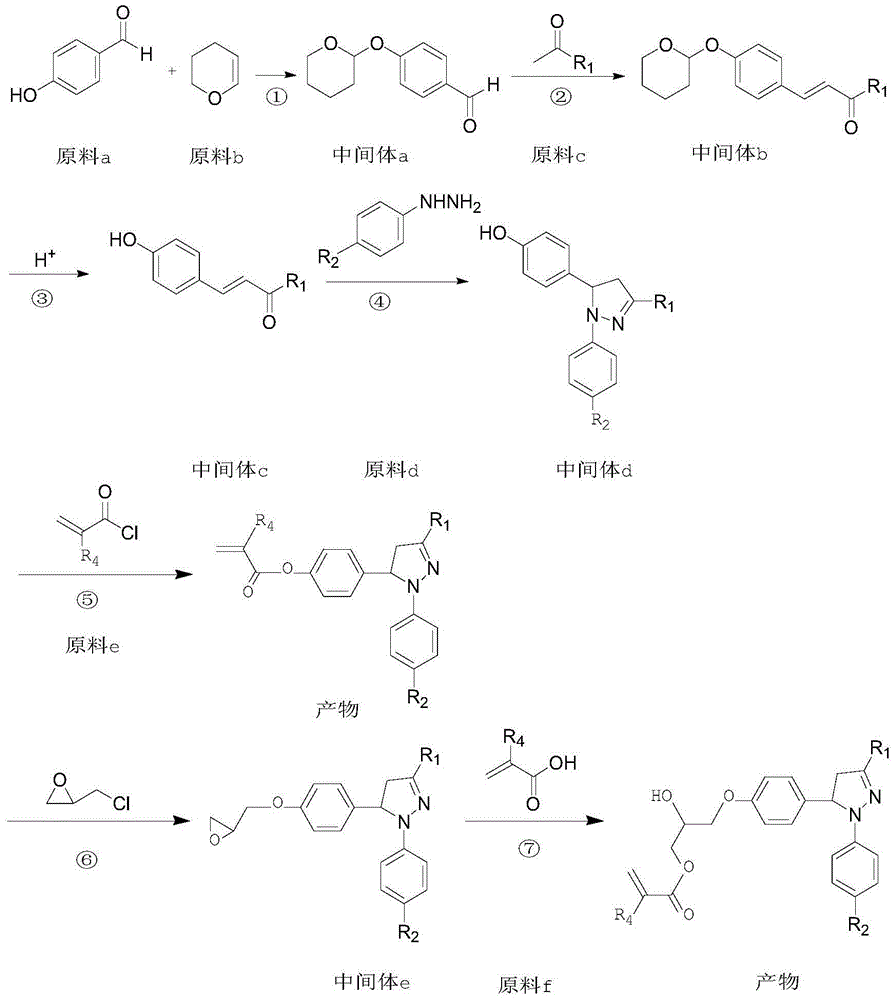

Method used

Image

Examples

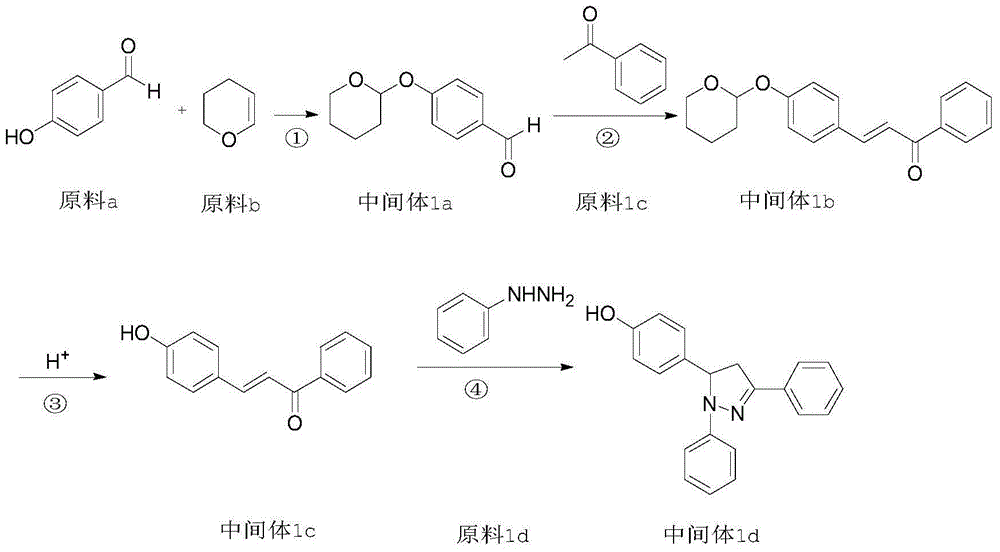

Embodiment 1

[0036]

[0037](1) Add 183g of p-hydroxybenzaldehyde, 5g of catalyst pyridinium p-toluenesulfonate, and 300mL of dichloromethane into a 1000mL four-neck flask, add 126g of dihydropyran dropwise at a temperature of 50°C, dropwise for about 1h, dropwise After completion, continue stirring for 10 h, track the reaction until the liquid phase does not change and close the reaction, and then remove the dichloromethane by rotary evaporation to obtain 275 g of intermediate 1a with a purity of 98%, which is directly used in the next reaction;

[0038] (2) Add 247g of intermediate 1a, 144g of acetophenone, and 300mL of methanol to a 1000mL four-neck flask, stir in a water bath at room temperature, add 80g of 40% sodium hydroxide solution dropwise within 2h, then continue to stir for 6h, and follow the reaction in the liquid phase to No change occurred, filtered, recrystallized from methanol, and dried to obtain 330 g of solid, namely intermediate 1b, with a purity of 93%;

[0039] (3...

Embodiment 2

[0046]

[0047] Add intermediate 1d (94.3g, 0.3mol), toluene (50mL), epichlorohydrin (27.8g, 0.3mol), tetrabutylammonium bromide (0.5g) to a 500mL four-necked flask, and control the temperature for 70 React at around ℃ for 5 hours, follow the liquid phase to complete the reaction, then lower it to room temperature, add 20g of sodium hydroxide, control the temperature below 30°C and react for 3 hours, follow the liquid phase to complete the reaction, then add 100mL of water and stir, extract the water layer with toluene, and combine The toluene layer was rotary evaporated to obtain 106.6 g of product intermediate e.

[0048] Take intermediate e (37.0g), methacrylic acid (8.6g, 0.1mol), toluene (30mL), triphenylphosphine (0.1g), p-hydroxyanisole (0.1g), react at 110°C for 5h, and react After completion, cool down to room temperature, wash the toluene layer with water, spin the toluene product solution, recrystallize methanol, and obtain 41.6 g of product 2 with a yield of 88%...

Embodiment 3-14

[0052] With reference to the method of Example 1 or 2, the product 3-14 with the structure shown below is synthesized:

[0053]

[0054]

[0055] performance evaluation

[0056] By preparing an exemplary photocurable composition (ie, a photosensitive resin composition), the application performance of the sensitizer represented by formula (I) of the present invention is evaluated.

[0057] 1. Preparation of performance evaluation objects

[0058]

[0059] Fully stir and mix the photosensitive resin composition and PGMEA (propylene glycol methyl ether acetate) with the composition shown in Table 1, and use a bar to coat the surface of a 19 μm thick polyethylene terephthalate film as a support Evenly coated on the surface, and then dried in a dryer at 95° C. for 4 minutes to form a photosensitive resin layer with a thickness of 40 μm.

[0060] Next, a polyethylene film having a thickness of 23 μm was bonded as a protective layer on the surface of the photosensitive re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com