High-conductivity heat-resisting aluminum alloy monofilament material and preparation method thereof

An aluminum alloy monofilament, high conductivity technology, applied in the direction of metal/alloy conductors, etc., can solve the problems of large loss and low conductivity of power transmission lines, reduce production costs, reduce impurity content, improve thermal stability and high temperature The effect of creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

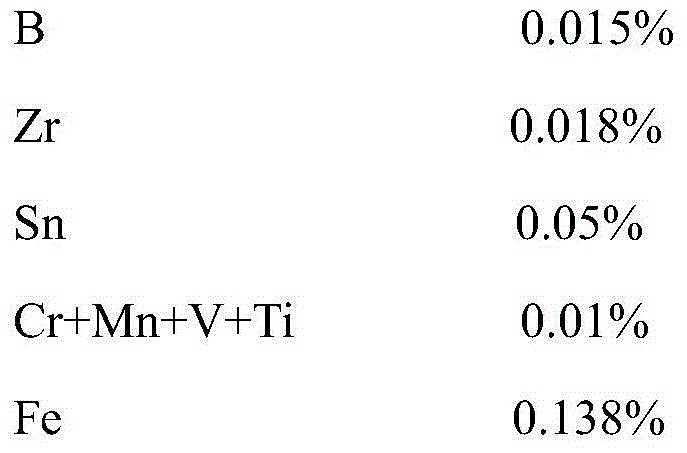

[0032] A high-conductivity heat-resistant aluminum alloy monofilament material, the components and their mass percentages are:

[0033]

[0034]

[0035] The preparation method of the above-mentioned high-conductivity heat-resistant aluminum alloy monofilament material comprises the following steps:

[0036] 1) Smelting: melting industrial pure aluminum ingots and Al-B master alloy at 730°C and standing still for 30 minutes, then removing slag, then melting Al-Zr alloy and Sn with a purity of 99.95% at 750°C;

[0037] 2) Refining: Refining molten aluminum with refining agent at 720°C for 15 minutes, standing still for 40 minutes and removing slag;

[0038] 3) Casting: pour the aluminum alloy liquid into a copper casting mold at 700°C to obtain an aluminum alloy ingot of 22×22×380mm;

[0039] 4) Rod making: heat the aluminum alloy ingot prepared in step 3) for 1 hour at 510°C, and then roll it into an aluminum alloy round rod with a diameter of Ф9.5mm;

[0040] 5) Wire dr...

Embodiment 2

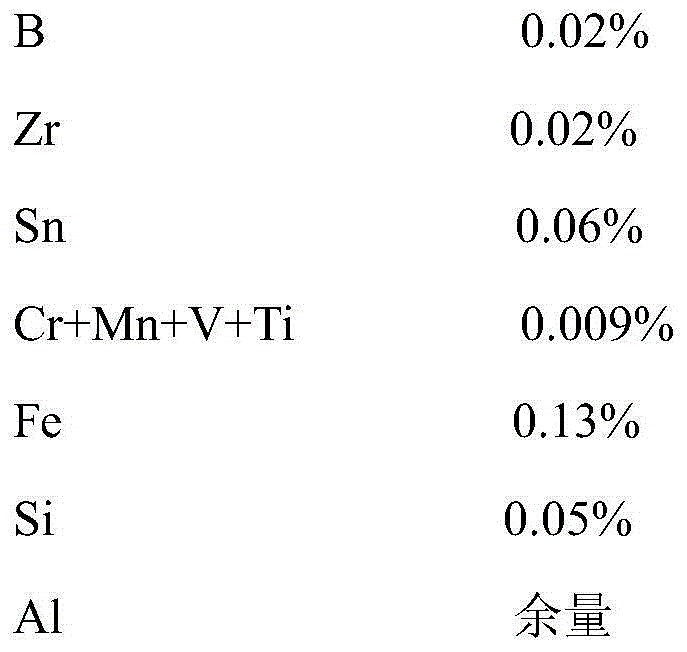

[0043] A high-conductivity heat-resistant aluminum alloy monofilament material, the components and their mass percentages are:

[0044]

[0045] The preparation method of the above-mentioned high-conductivity heat-resistant aluminum alloy monofilament material comprises the following steps:

[0046] 1) Smelting: melting industrial pure aluminum ingots and Al-B master alloy at 735°C and standing still for 30 minutes, then removing slag, and then melting Al-Zr alloy and Sn with a purity of 99.95% at 750°C;

[0047] 2) Refining: Refining molten aluminum with refining agent at 725°C for 15 minutes, standing still for 40 minutes and removing slag;

[0048] 3) Casting: pour the aluminum alloy liquid into a copper casting mold at 705°C to obtain an aluminum alloy ingot of 22×22×380mm;

[0049] 4) Rod making: heat the aluminum alloy ingot prepared in step 3) for 1 hour at 515°C, and then roll it into an aluminum alloy round rod with a diameter of Ф9.5mm;

[0050] 5) Wire drawing:...

Embodiment 3

[0053] A high-conductivity heat-resistant aluminum alloy monofilament material, the components and their mass percentages are:

[0054]

[0055] The preparation method of the above-mentioned high-conductivity heat-resistant aluminum alloy monofilament material comprises the following steps:

[0056] 1) Smelting: melting industrial pure aluminum ingots and Al-B master alloy at 740°C and standing for 30 minutes, then removing slag, then melting Al-Zr alloy and Sn with a purity of 99.95% at 750°C;

[0057] 2) Refining: Refining molten aluminum with refining agent at 730°C for 15 minutes, standing still for 40 minutes and removing slag;

[0058] 3) Casting: pour the aluminum alloy liquid into a copper casting mold at 710°C to obtain an aluminum alloy ingot of 22×22×380mm;

[0059] 4) Rod making: heat the aluminum alloy ingot prepared in step 3) for 1 hour at 520°C, and then roll it into an aluminum alloy round rod with a diameter of Ф9.5 mm;

[0060] 5) Wire drawing: at 40° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com