High-grade liquid crystal display panel intermediary paper production process

A production process and liquid crystal screen technology, which is applied in paper, papermaking, papermaking machines, etc., can solve the problems of easily scratched substrates, large space occupation, and high scrap rate, and achieve low smoothness, small smoothness, and film surface fine and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

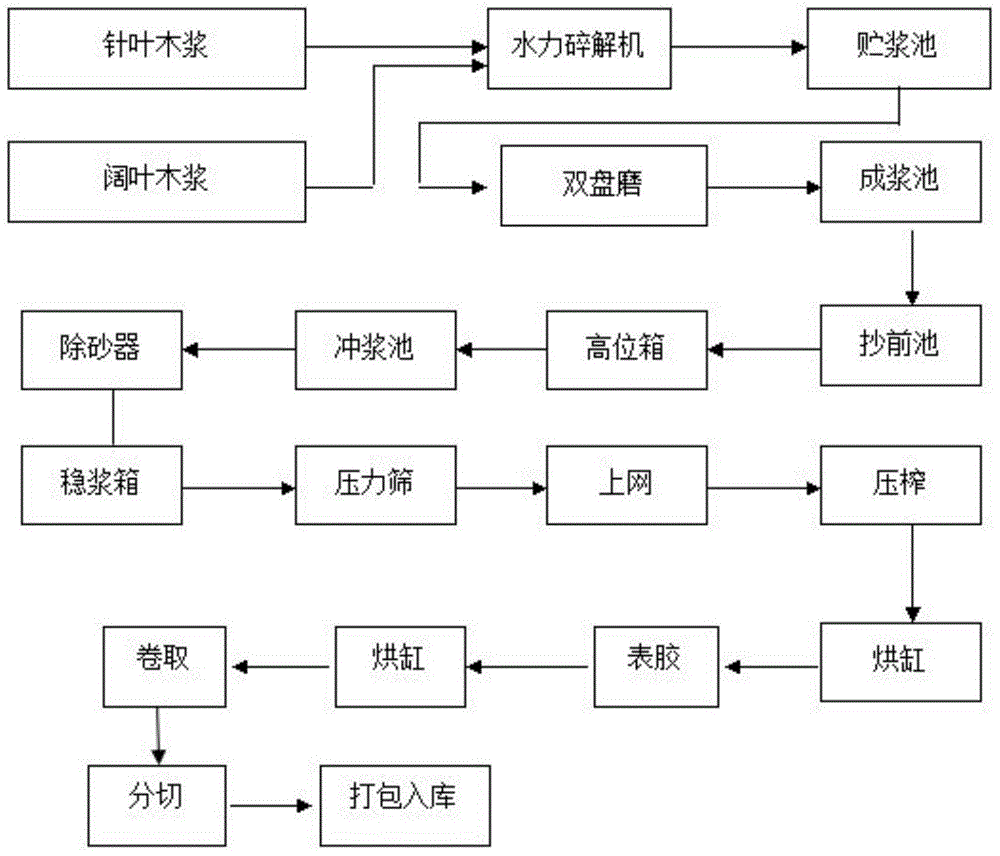

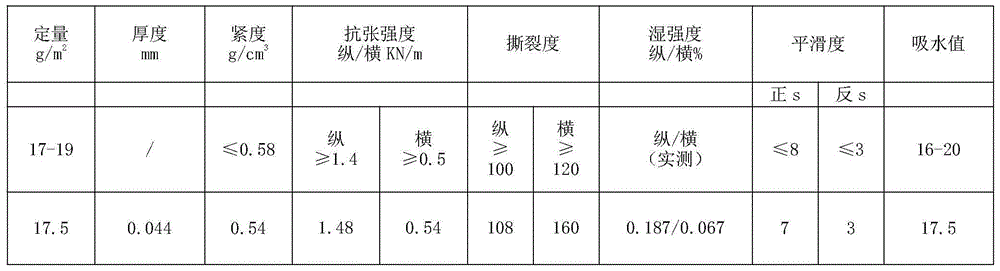

[0022] High-grade LCD screen panel interlayer paper production process, such as figure 1 : Add 420kg northern wood pulp board and 180kg cloth wide pulp board into the hydraulic disintegrator for disintegration. The speed of the hydraulic disintegrator is based on the pulp board being fully disintegrated, and the disintegration time is controlled at 20-25min; disintegration Finally, the slurry enters the slurry storage tank, the control liquid level is 1.8m, and the control concentration is 4.0%. The function of the slurry storage tank is to store the crushed slurry for grinding and beating; Grinding, 2# double-disc mill consisting of double-disc mill, repeat the above operation five times, and then make a slurry, measure the degree of knocking and wet weight each time the disc mill is passed, control the current of 1# disc mill to 120A, and the current of 2# disc mill to be 150~160A, the final measurement of pulping degree is 40~45°SR, wet weight is 3.0~3.5g; the slurry enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com