A Periodic Test Device for Protection System of PWR Nuclear Power Plant

A technology of protection system and regular test, applied in general control system, control/regulation system, electrical testing/monitoring, etc. It can solve the problem of lack of injection signal readback function, inability to judge injection signal quality, and no on-site parameter calculation, etc. problems, to achieve the effect of reliable test results, guaranteed reliability and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

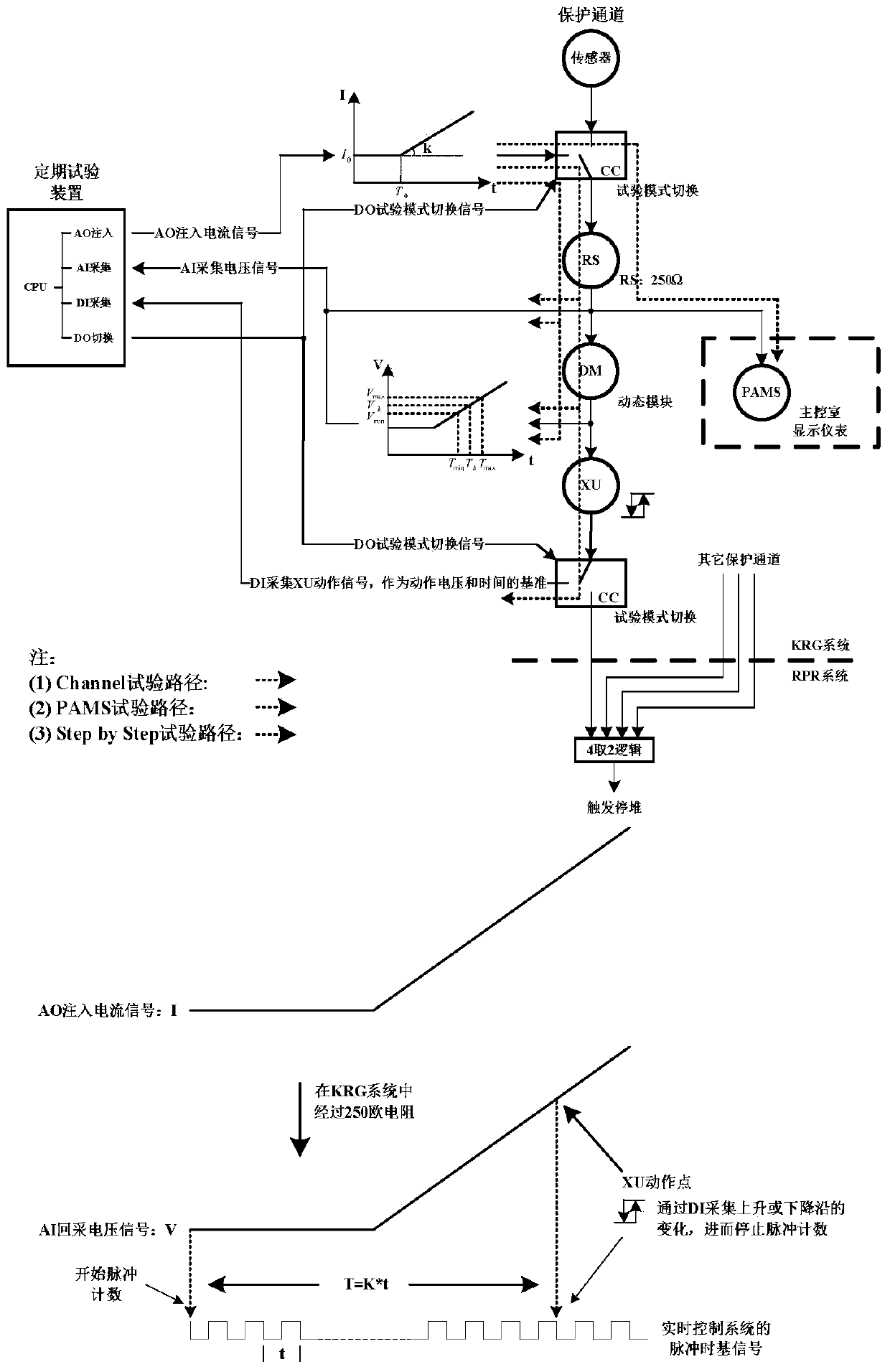

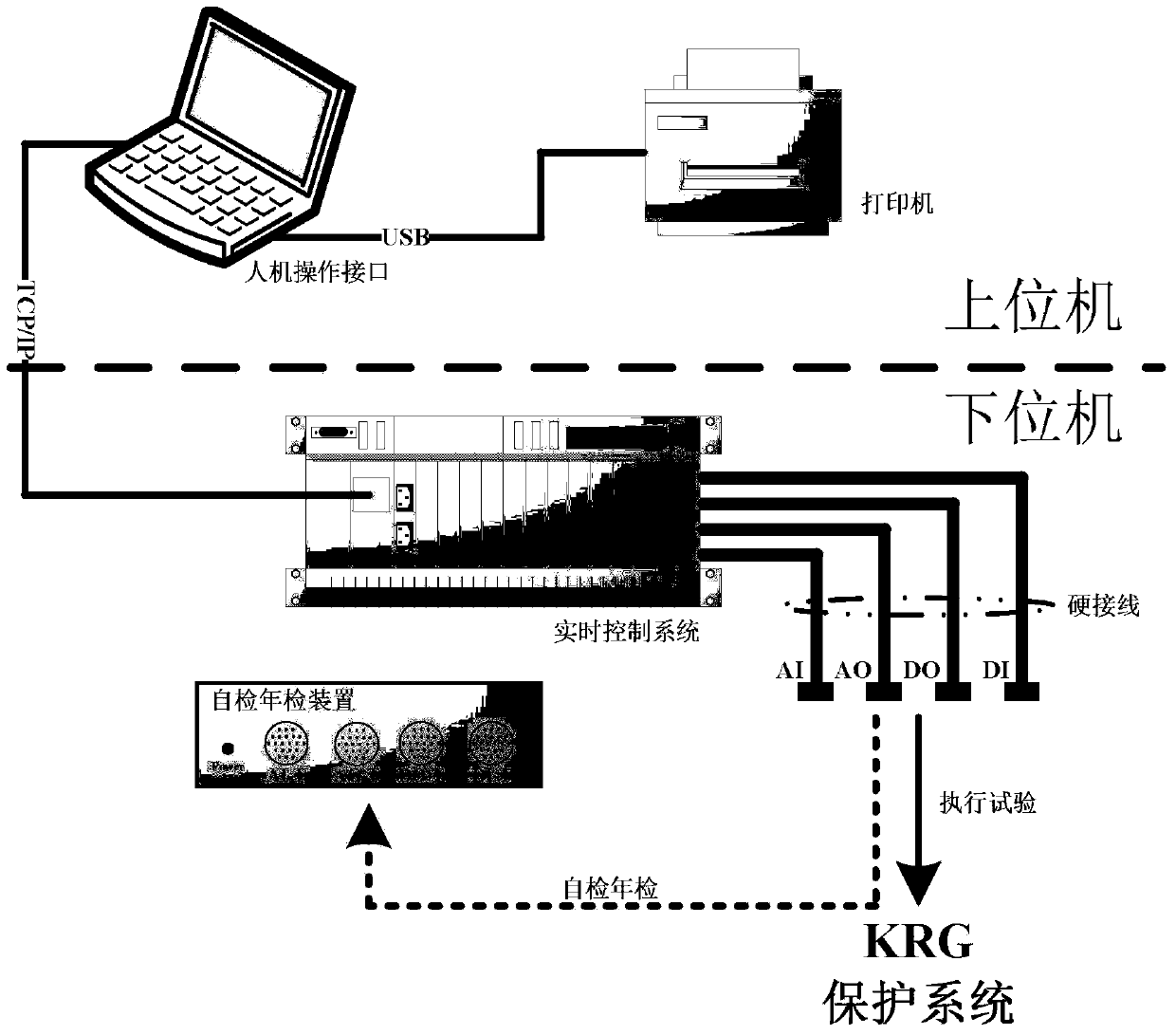

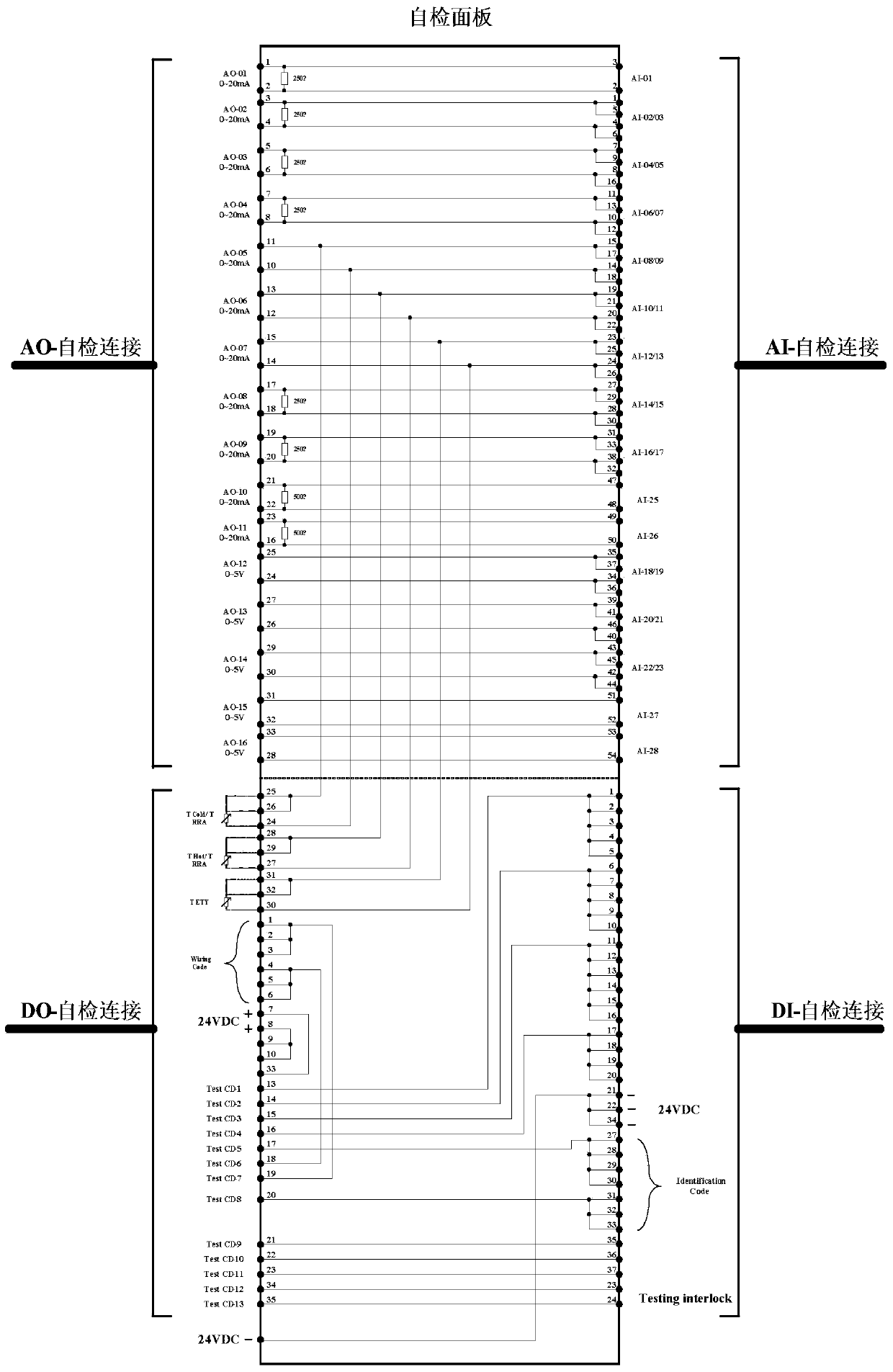

[0056] This test device (KRG-TESTER) is designed to verify the important analog channel acquisition and processing system of the pressurized water reactor nuclear power plant. test. The function of the test device is to check the availability of the KRG system protection measurement channel during reactor operation. The test device provides an analog signal as close to the actual as possible, and injects the analog signal into the protection system. By checking whether the signal conversion error, whether the threshold relay operates, and whether the action threshold error meets the design requirements, etc., it is judged whether the KRG system protection measurement channel is Fault occurs, therefore, the regular test of KRG is divided into three parts: verification protection channel threshold module XU test (Channel test), display channel test from KRG system to main control room (PAMS test) and dynamic module test of protection channel (Step by Step test).

[0057] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com