ANSYS-based crosslinking polyethylene insulated cable temperature field finite element calculation method

A technology of cross-linked polyethylene and insulated cables, which is applied in the field of power cables, can solve the problems of solving huge equations, many boundaries of the boundary element method, and a large amount of calculation, and achieves the effect of improving the operation level, high accuracy, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

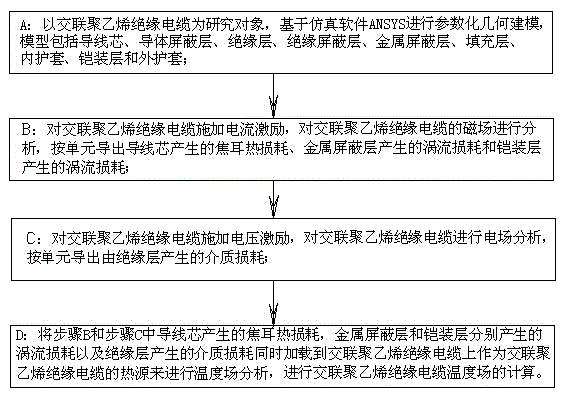

[0037] Such as figure 1 As shown, the present invention is based on the ANSYS cross-linked polyethylene insulated cable temperature field finite element calculation method, comprising the following steps in turn:

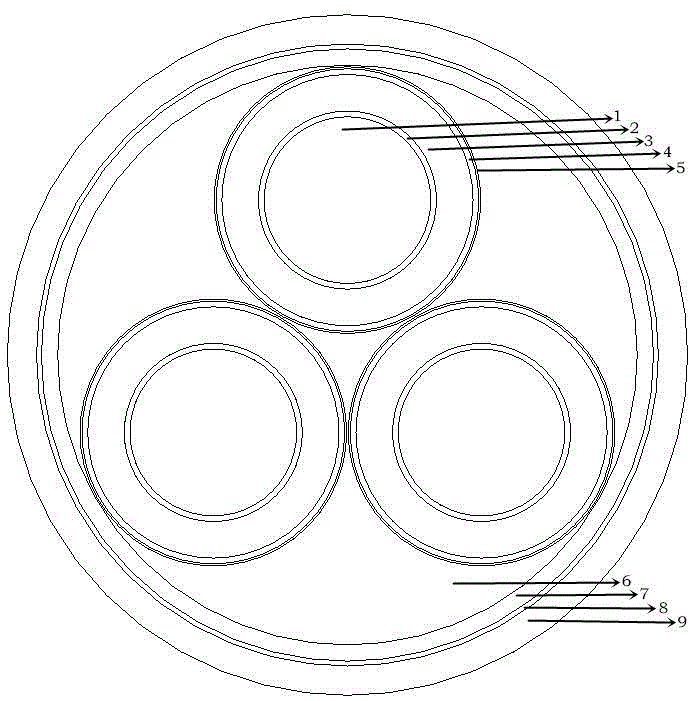

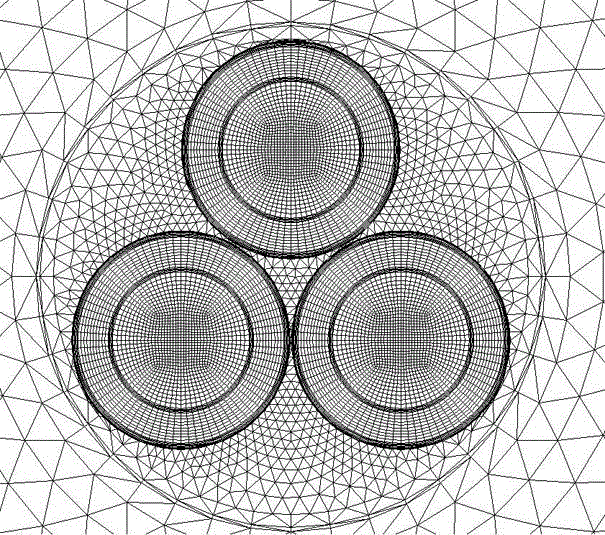

[0038] A, taking the 10kV XLPE insulated cable YJLV22-10-3*300 as the research object, based on the simulation software ANSYS for parametric geometric modeling, the model includes conductor core 1, conductor shielding layer 2, insulating layer 3, Insulation shielding layer 4, metal shielding layer 5, filling layer 6, inner sheath 7, armor layer 8 and outer sheath 9, the technical parameters of YJLV22-10-3*300 XLPE insulated cable are shown in Table 1 ; XLPE insulated cable model structure schematic diagram as figure 2 As shown, the modeling specifically includes the following steps:

[0039]A1: According to the national standard GB50217-94 power engineering cable design specification and DL / T 5221-2005 urban power cable circuit design technical regulations, consi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com