Hydrogel antibacterial gauze dressing and preparation method therefor

A technology of hydrogel and hydrogel layer, applied in the field of hydrogel antibacterial gauze dressing and preparation thereof, can solve the problems of weak toxicity and side effects of nano silver, and achieve fast healing, easy removal and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

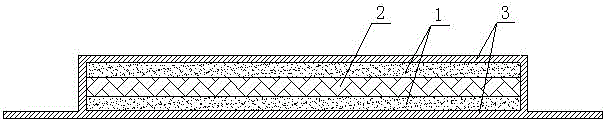

Image

Examples

preparation example Construction

[0037] The preparation method of hydrogel antibacterial gauze dressing of the present invention can be carried out according to the following steps:

[0038] The first step: disperse the above-mentioned hydrophilic polymer and glycerin in the purified water in sequence, mix and stir evenly, after fully swelling, add the above-mentioned inorganic nano-antibacterial agent by weight, mix and stir again to form a uniform mixture, that is is a hydrogel;

[0039] The second step: uniformly coat the hydrogel obtained in the first step on the support layer to form a hydrogel layer, and then cover the exposed parts of the hydrogel layer and the support layer with a protective layer, to obtain finished product.

[0040] In order to clearly illustrate the meaning of the present invention picture , the present invention will be described in more detail below by two groups of comparative experiments.

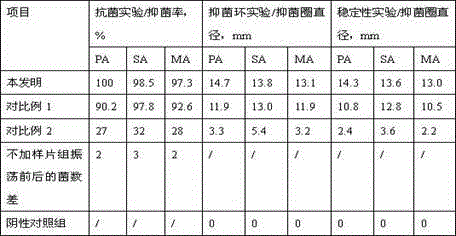

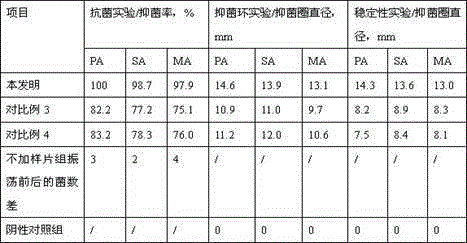

[0041] 1) Change the types of inorganic nano-antibacterial agents

[0042] In the p...

Embodiment 1

[0081] Weigh 20g of hydroxyethylcellulose and 30g of sodium carboxymethylcellulose and disperse them in 890g of purified water. After fully swelling, add 10g of glycerin, mix well, then add 50g of nano-zinc oxide powder, and stir well to form a uniform mixture. A hydrogel is obtained.

[0082] The hydrogel obtained above is evenly coated on the polyester fiber gauze of the supporting layer, and then the exposed part of the hydrogel layer and the supporting layer is covered with a PE film as a protective layer to obtain the finished product of the present invention.

[0083] The coating weight of hydrogel layer is 500g / m in the present embodiment 2 .

[0084] In order to facilitate portability, a release paper can be arranged on the outside of the protective layer.

[0085] Among them, the molecular weight of hydroxyethyl cellulose is 100,000-30,000, the molecular weight of sodium carboxymethyl cellulose is 15,000-30,000, and the degree of deacetylation is 85%; The average p...

Embodiment 2

[0087] Weigh 10g of sodium carboxymethylcellulose and disperse it in 905g of purified water. After fully swelling, add 35g of glycerin, mix well, then add 50g of nanometer zinc oxide powder, stir well and form a uniform mixture to obtain a hydrogel.

[0088] The hydrogel obtained above is evenly coated on the polyester fiber gauze of the supporting layer, and then the exposed part of the hydrogel layer and the supporting layer is covered with a PU film as a protective layer to obtain the finished product of the present invention.

[0089] The coating weight of hydrogel layer is 550g / m in the present embodiment 2 .

[0090] In order to facilitate portability, a release paper can be arranged on the outside of the protective layer.

[0091] Among them, the molecular weight of sodium carboxymethylcellulose is 50,000-100,000, and the degree of deacetylation is 75%; the average particle size of zinc oxide powder, an inorganic nano-antibacterial agent, is 10-100nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com