Man-made ebony production method

A production method and technology of artificial ebony, applied in the direction of wood treatment, impregnating wood, manufacturing tools, etc., can solve the problems of uneven carbonization and long formation time of ebony

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

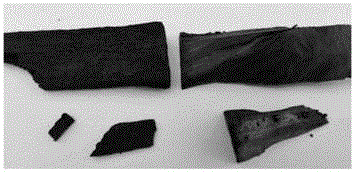

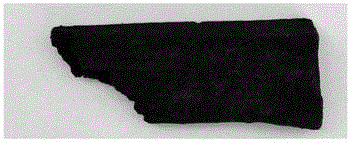

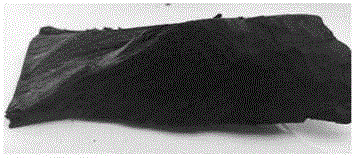

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment this law is described in detail:

[0023] 1. Method

[0024] ①The first stage of fermentation

[0025] The preparation method of described lactic acid bacteria-saccharomyces fermented liquid:

[0026] A. Culture medium preparation

[0027] Weigh 200g of polyvalent peptone, 10g of tryptone, 5g of yeast extract, 5g of sodium chloride, 50g of beef extract, 0.4g of cysteine, 5g of hemin, and 676mL of beef extract, and adjust the pH value to 7.4 after mixing. 121°C damp heat sterilization for 30 minutes;

[0028] B, preparation of Lactobacillus bulgaricus liquid

[0029] Inoculate Lactobacillus bulgaricus delbrueckii into the above medium at a ratio of 5-10% of the mass of the medium, and culture it anaerobically at 28-38°C for 48 hours to obtain Lactobacillus bulgaricus delbrueckii liquid;

[0030] C. Preparation of thermophilic lactic acid streptococcus liquid

[0031] Streptococcus thermophilic lactis was inoculated into the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com