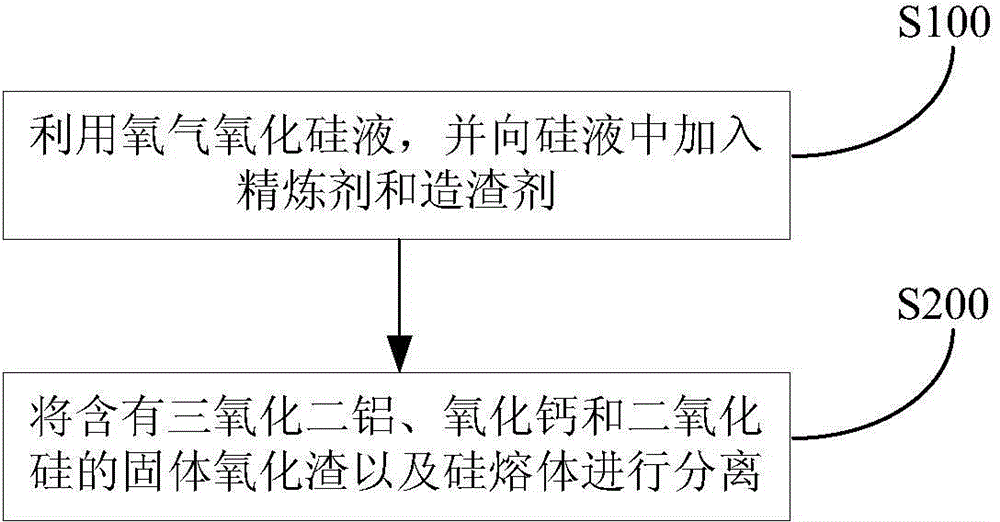

Method used for processing silicon liquid

A technology for silicon liquid and silicon melt, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of inadequate management and control, increased cost, large silicon loss rate, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

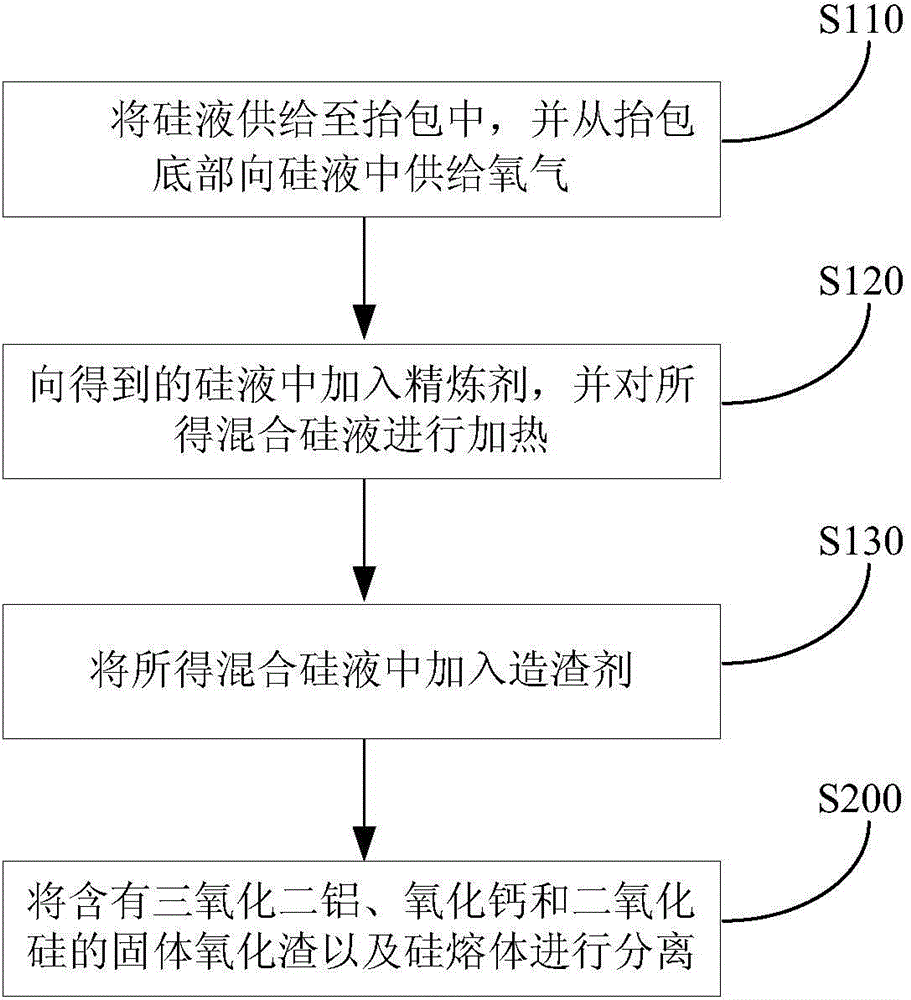

[0040] First, discharge the silicon liquid with a silicon content greater than 95% released from the submerged arc furnace into a ladle where oxygen can be blown at the bottom. Supply compressed air with a flow rate of 300L / min and ensure that the air pipe is unblocked. When the silicon liquid flows into the ladle, cut off the compressed air and supply oxygen with a flow rate of 600L / min to the ladle through the oxygen inlet, and then wait for the silicon in the ladle to After the liquid reaches 5000kg, add 45-150kg of calcium oxide refining agent to the silicon liquid, cover it with straw to control the temperature, and use a digital display thermometer to measure the temperature of the silicon liquid, control the temperature of the silicon liquid at 1450-1550 degrees Celsius, and then Add 30~100kg of slagging agent (containing 30~40wt% calcium carbonate, 20~30wt% magnesium sulfate and 30~40wt% zinc oxide) in the obtained mixed silicon liquid, thereby can obtain The mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com