Method for improving water vapor barrier property of polymer film by virtue of surface crosslinking

A polymer film and water vapor barrier technology, which is used in the field of improving the water vapor barrier properties of polymer films, can solve problems such as damage and poor stability, and achieve the effect of firm bonding, high water vapor barrier ability, and retention of physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

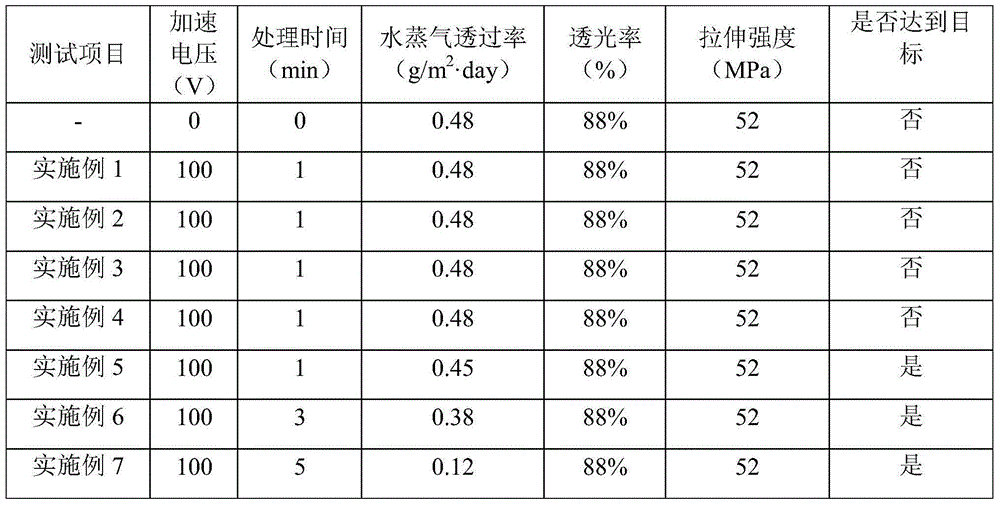

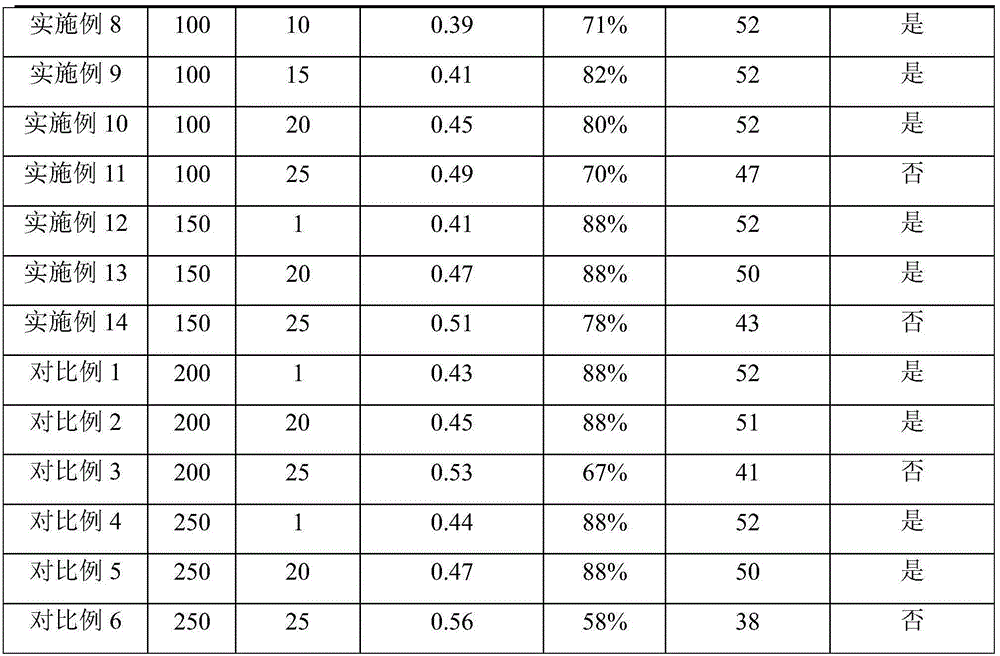

Examples

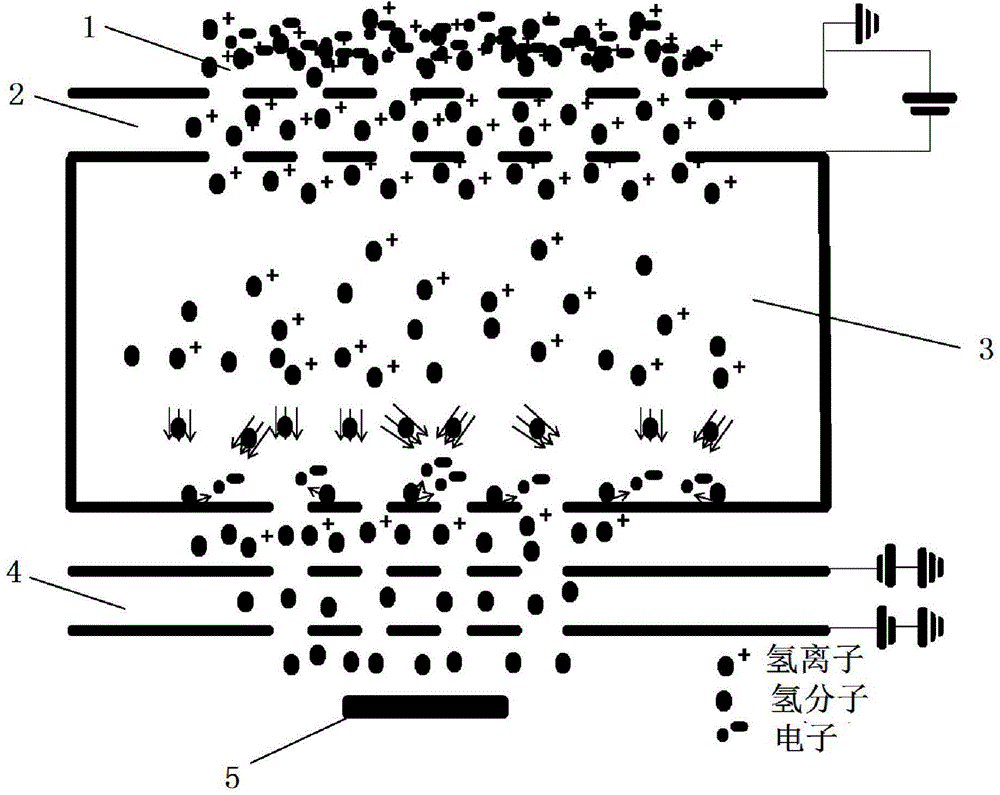

Embodiment 1

[0030]Fix the polychlorinated p-xylylene film (thickness 100 μm) on the sample stage of the superthermal hydrogen system (CN 102414359 A), the distance of the processed polymer film sample from the plasma discharge area is 50cm, and the place above the film sample is 10-20cm There are two repelling electrode plates, positive and negative, respectively. Turn on the vacuum pump to evacuate, then pass in 14SCCM (standard ml / min) hydrogen, and turn on the microwave plasma, turn on the acceleration power supply and the repulsion power supply, the acceleration voltage is 100V, and the film sample is bombarded with hydrogen for 1min to obtain modification and improve the surface water vapor barrier. performance polymer films.

Embodiment 2

[0032] The same polychlorinated p-xylylene film as in Example 1 is fixed on the sample stage of the superthermohydrogen system, and the processed polymer film sample is 60 cm away from the plasma discharge area, and the 10-20 cm above the film sample is respectively placed There are positive and negative two repelling electrode plates. Turn on the vacuum pump to make the vacuum in the cavity reach 6×10 -4 At Pa, 14SCCM hydrogen gas was introduced in sequence, and the microwave plasma was turned on, and the acceleration power supply and repulsion power supply were turned on. The microwave power was 300W, the acceleration voltage was 100V, and the film sample was bombarded with hydrogen for 1min to obtain a film with enhanced surface water vapor barrier properties.

Embodiment 3

[0034] The polychlorinated p-xylylene film (thickness 100 μm) was ultrasonically cleaned in a container containing acetone for 15 min, and dried with nitrogen. Fix the film on the sample stage of the superthermal hydrogen system. The distance between the processed polymer film sample and the plasma discharge area is 45cm, and two positive and negative repelling electrode plates are respectively placed at 10-20cm above the film sample. Turn on the vacuum pump to make the vacuum in the cavity reach 6×10 -4 At Pa, 14 SCCM hydrogen gas was introduced in sequence, and the microwave plasma was turned on, and the acceleration power supply and the repulsion power supply were turned on. The microwave power was 300W, the acceleration voltage was 100V, and the film sample was bombarded with hydrogen for 1min to obtain a film with enhanced surface water vapor barrier properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com