Formula of antibacterial PE (polyethylene) plastic dustbin

A technology of waste bin and formula, applied in the field of waste bin materials, can solve the problems of ordinary people's health impact, physical health damage, bacteria easily breed, etc., and achieve the effect of inhibiting the growth of bacteria, reducing damage, and protecting public health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

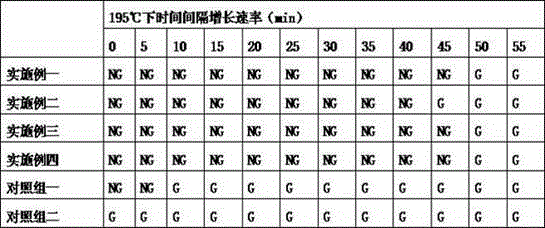

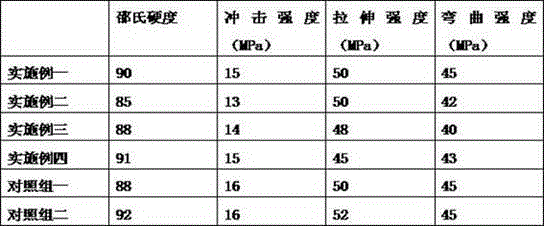

Examples

Embodiment 1

[0039] Example 1: polyethylene resin: 900g; diisononyl phthalate: 30g; calcium zinc stabilizer: 20g; zinc pyrithione: 25g; glass fiber: 200g; 5 g; hydrotalcite: 15 g.

[0040] The above-mentioned plastic composite material is used to make a trash can according to a conventional manufacturing method in the field. More specifically, the manufacturing method of the trash can described in this embodiment is as follows:

[0041] Weigh the raw materials according to the weight ratio of the above ingredients, add all the raw materials except the glass fiber into the barrel and mix evenly, heat and melt, put the weighed glass fiber into the grinding tool, and then, the mixing and melting is completed The slurry is quickly injected into the mold of the closed trash can, and after pressure maintenance, injection molding, the mold is opened, the product is taken out, and the edges are properly trimmed to obtain a plastic trash can.

Embodiment 2

[0042] Example 2: Polyethylene resin: 850g; Dioctyl terephthalate: 35g; Calcium zinc stabilizer: 15g; Zinc pyrithione: 25g; Glass fiber: 200g; Nano barium sulfate: 10g; Pigment: 5g; Hydrotalcite: 15g.

[0043] The above-mentioned plastic composite material is used to make a trash can according to a conventional manufacturing method in the field. More specifically, the manufacturing method of the trash can described in this embodiment is as follows:

[0044] Weigh the raw materials according to the weight ratio of the above ingredients, add all the raw materials except the glass fiber into the barrel and mix evenly, heat and melt, put the weighed glass fiber into the grinding tool, and then, the mixing and melting is completed The slurry is quickly injected into the mold of the closed trash can, and after pressure maintenance, injection molding, the mold is opened, the product is taken out, and the edges are properly trimmed to obtain a plastic trash can.

Embodiment 3

[0045] Example three: polyethylene resin: 900g; dioctyl sebacate: 35g; barium zinc stabilizer: 20g; zinc pyrithione: 30g; glass fiber: 200g; nano calcium carbonate: 10g; pigment: 5g; water Talc: 20g.

[0046] The above-mentioned plastic composite material is used to make a trash can according to a conventional manufacturing method in the field. More specifically, the manufacturing method of the trash can described in this embodiment is as follows:

[0047] Weigh the raw materials according to the weight ratio of the above ingredients, add all the raw materials except the glass fiber into the barrel and mix evenly, heat and melt, put the weighed glass fiber into the grinding tool, and then, the mixing and melting is completed The slurry is quickly injected into the mold of the closed trash can, and after pressure maintenance, injection molding, the mold is opened, the product is taken out, and the edges are properly trimmed to obtain a plastic trash can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com