Method for preparing functional hydrotalcite extremely easy to intercalate by adopting trihydroxymethyl molecules

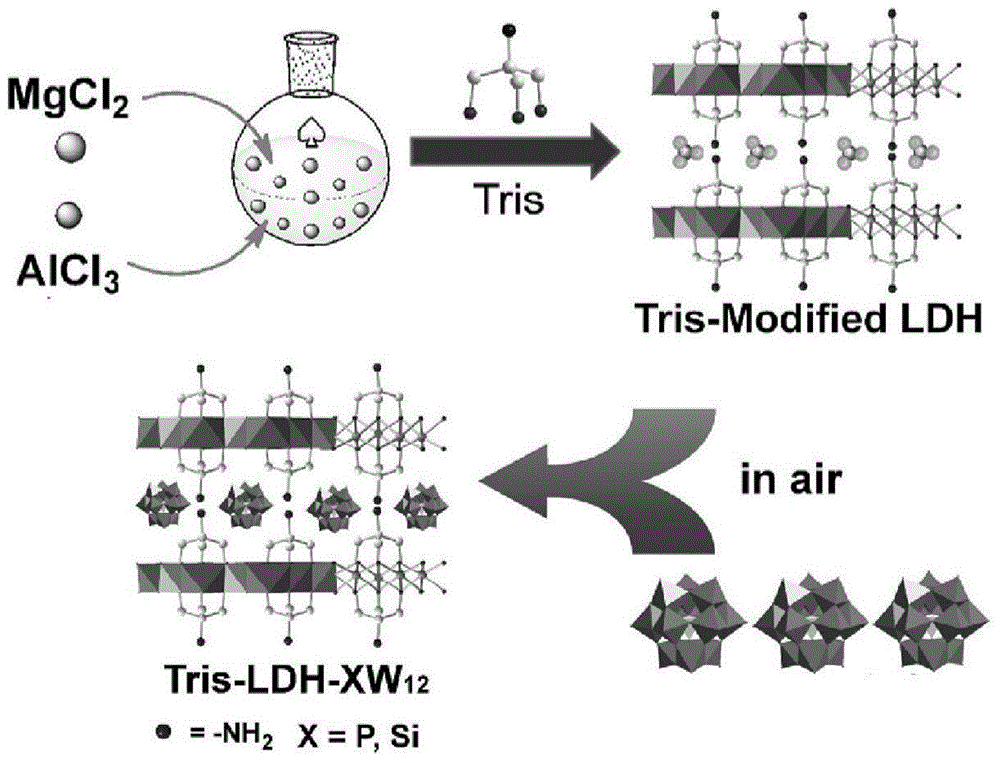

A trimethylol, hydrotalcite technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, fibrous fillers, etc., can solve the problem of difficulty in inserting hydrotalcite between layers, and reduce the difficulty of ion exchange, Simplified synthesis method, reduced lattice energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

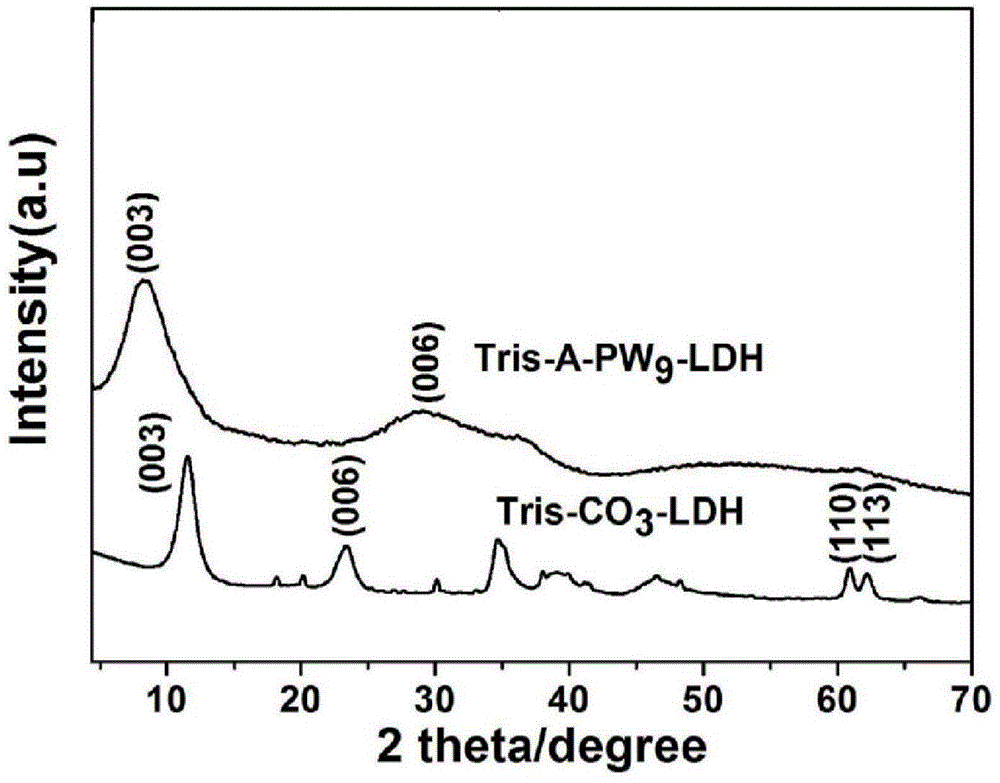

[0018] a. Take 13.1mmol MgCl 2 ·6H 2 O, 6.9 mmol AlCl 3 ·6H 2 O mixed and dissolved in 100ml deionized water; 0.2mol trishydroxymethylaminomethane was dissolved in 100ml deionized water; the prepared two solutions were mixed and stirred for 30 minutes to obtain a colloidal solution, which was then transferred to an autoclave, and Aged at 80°C for 12 hours, then centrifuged and washed;

[0019] b. Disperse the precipitate obtained in step a in 100ml 0.5M NaCO 3 solution, stirred for 1 h, washed by centrifugation, and dried to obtain tris-modified hydrotalcite, which is denoted as Tris-NH 2 -CO 3 -LDH;

[0020] c. Take 2.436g Na 9 [A-PW 9 o 34 ]·7H 2 O was dissolved in 10ml of deionized water, completely dissolved, then added the hydrotalcite prepared in step b, stirred for 6 hours, washed by centrifugation for 2 times, and vacuum-dried to obtain polyacid Na 9 [A-PW 9 o 34 ]·7H 2 O intercalated hydrotalcite composites, abbreviated as Tris-NH 2 -A-PW 9 -LDH.

Embodiment 2

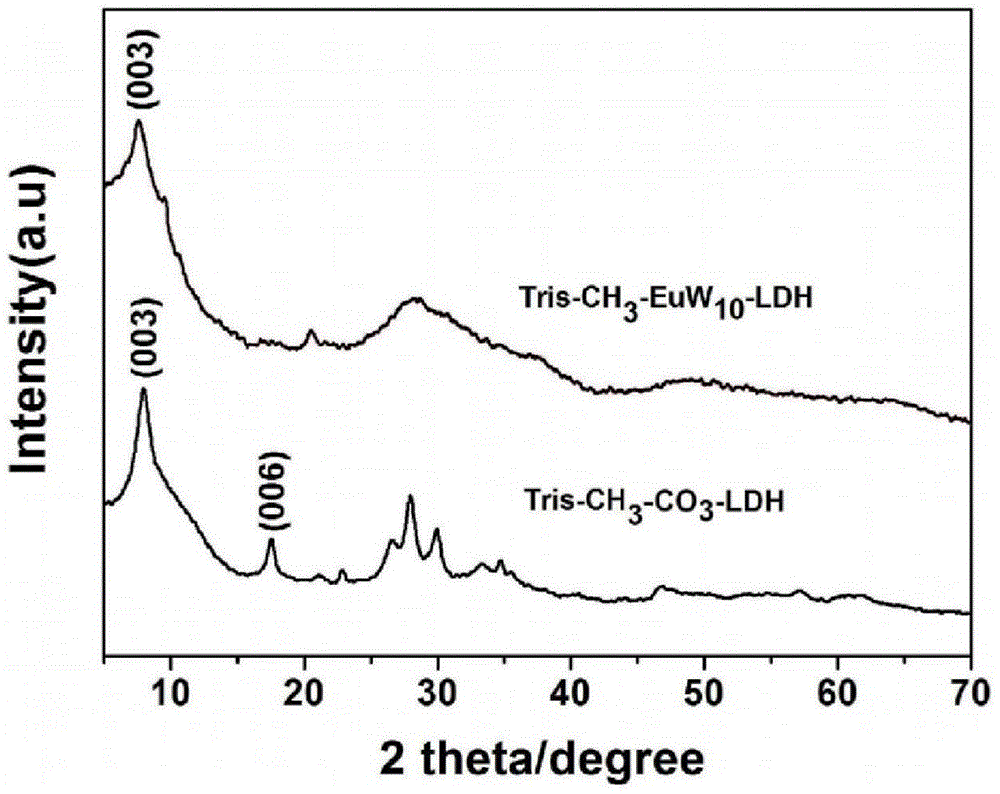

[0022] a. Take 13.1mmol MgCl 2 ·6H 2 O, 6.9 mmol AlCl 3 ·6H 2O mixed and dissolved in 100ml deionized water; 0.2mol 1,1,1-trimethylolethane was dissolved in 100ml deionized water; the prepared two solutions were mixed and stirred for 30 minutes to obtain a colloidal solution, and then transferred Put it in an autoclave, age at 80°C for 12h, and then centrifuge and wash;

[0023] b. Disperse the product obtained in step a in 100ml 0.5M NaCO 3 solution, stirred for 1 hour, washed by centrifugation, and dried to obtain 1,1,1-trimethylolethane-modified hydrotalcite, denoted as Tris-CH 3 -CO 3 -LDH;

[0024] c. Take 3.35g Na 9 [EuW 10 o 36 ]·32H 2 O was dissolved in 10ml of deionized water, completely dissolved, and the hydrotalcite prepared in step b was added to the polyacid solution, stirred for 6 hours, centrifugally washed twice, and vacuum-dried to obtain polyacid Na 9 [EuW 10 o 36 ]·32H 2 O intercalated hydrotalcite composites, abbreviated as Tris-CH 3 -EuW 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com