Device and process for preparing natural gas by virtue of double-fluidization bed gasification of biomass

A dual fluidized bed, fluidized bed technology, applied in the chemical industry, sustainable manufacturing/processing, granular/powder fuel gasification, etc. Wide range of effects with flexible temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

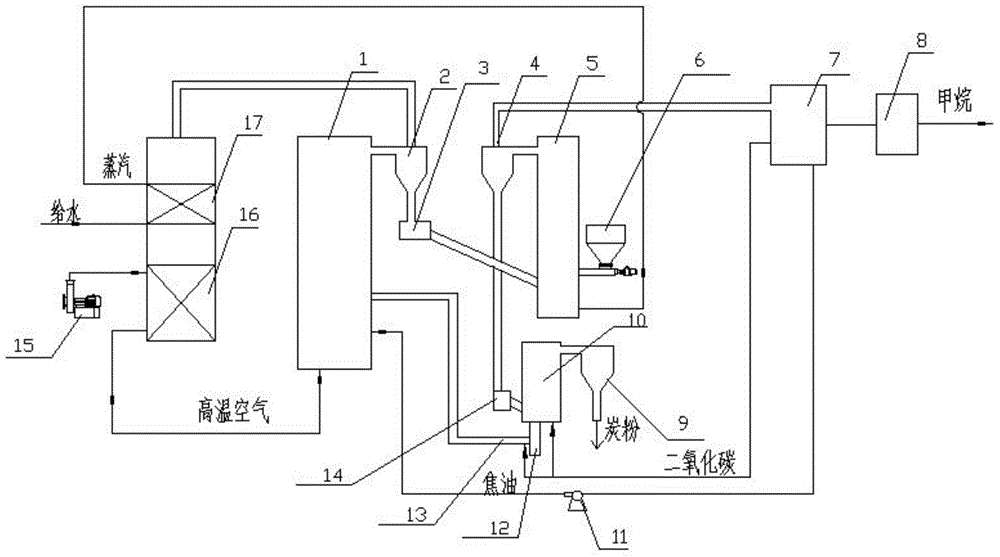

[0038] Wood chips with a moisture content of 18% and a particle diameter of 5mm are fed into the fluidized bed pyrolysis gasification furnace 5 by the feeding device 6, and the raw materials are heated by the 893°C high-temperature heat carrier 0.5mm quartz sand delivered from the fluidized bed combustion furnace 1 The pyrolysis and gasification reaction occurs under the condition of fluidized bed pyrolysis and gasification furnace 5, and the temperature inside the fluidized bed pyrolysis gasification furnace 5 is 835°C, generating high-temperature pyrolysis gas and biochar with a tar content of 7%, and the biochar and heat carrier are carried by the pyrolysis gas into the gas cyclone 4 To achieve gas-solid separation, the pyrolysis gas enters the gas purification and purification device 7, and the biochar and heat carrier enter the biochar cooling and separating furnace 10 through the feeder 2 14, and the temperature of the biochar cooling and separating furnace 10 is 350 °C; ...

Embodiment 2

[0040] The moisture content is 35%, and the particle diameter is 2mm bamboo chips are fed into the fluidized bed pyrolysis gasification furnace 5 by the feeding device 6, and the raw material is heated by the 845 ℃ high-temperature heat carrier 2mm ceramic ball delivered by the fluidized bed combustion furnace 1 The pyrolysis and gasification reaction occurs under the condition of fluidized bed pyrolysis and gasification furnace 5. The temperature in the fluidized bed pyrolysis gasification furnace 5 is 775°C, and high-temperature pyrolysis gas and biochar with a tar content of 5% are generated. The biochar and heat carrier are carried by the pyrolysis gas into the gas cyclone 4 To achieve gas-solid separation, the pyrolysis gas enters the gas purification and purification device 7, and the biochar and heat carrier enter the biochar cooling and separation furnace 10 through the feeder 2 14, and the temperature of the biochar cooling and separation furnace 10 is 310 ° C; The dec...

Embodiment 3

[0042] The straw with a moisture content of 42% and a particle length of 10mm is fed into the fluidized bed pyrolysis gasification furnace 5 by the feeding device 6, and the raw material is heated by a 591°C high-temperature heat carrier 1mm alumina ball delivered from the fluidized bed combustion furnace 1 The pyrolysis and gasification reaction occurs under the condition of fluidized bed pyrolysis and gasification furnace 5. The temperature inside the fluidized bed pyrolysis gasification furnace 5 is 540°C, and high-temperature pyrolysis gas and biochar with a tar content of 6% are generated. The biochar and heat carrier are carried by the pyrolysis gas into the gas cyclone 4 To achieve gas-solid separation, the pyrolysis gas enters the gas purification and purification device 7, and the biochar and heat carrier enter the biochar cooling and separating furnace 10 through the feeder 2 14, and the temperature of the biochar cooling and separating furnace 10 is 240 ° C; The deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com