An air-floating guide rail suitable for ultra-precision detection or ultra-high-precision processing equipment

A technology of processing equipment and air-floating guide rails, which is applied in the direction of mechanical equipment, bearings, shafts and bearings, etc., can solve the problems of restricted application range, high working air pressure, and poor bearing capacity, and achieve excellent speed control performance, improved bearing capacity, The effect of air consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples;

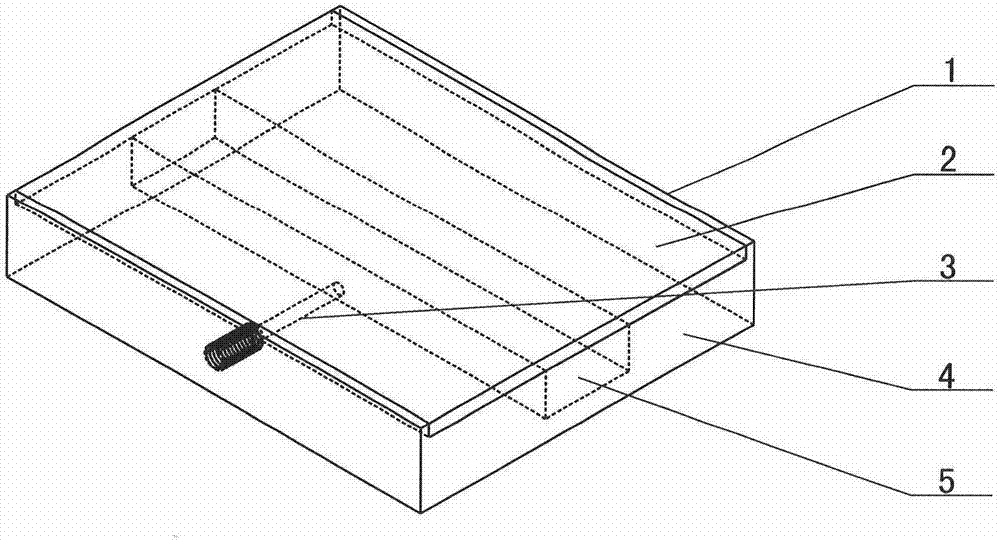

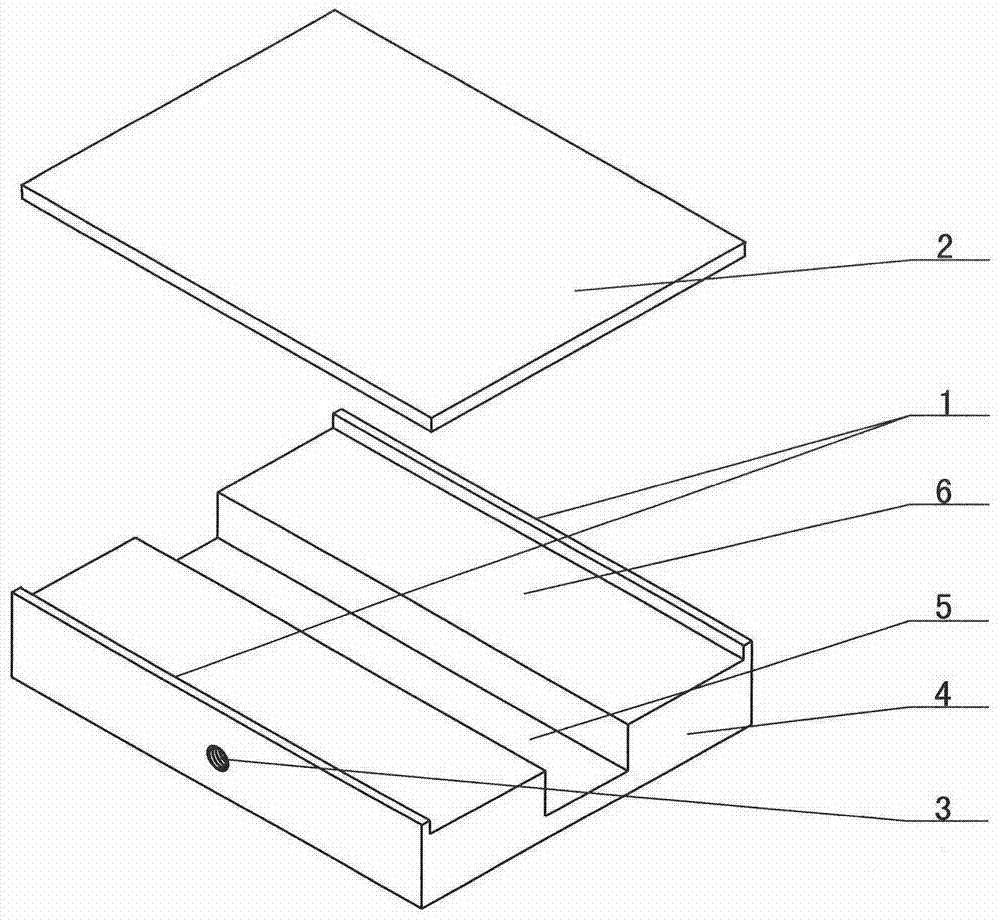

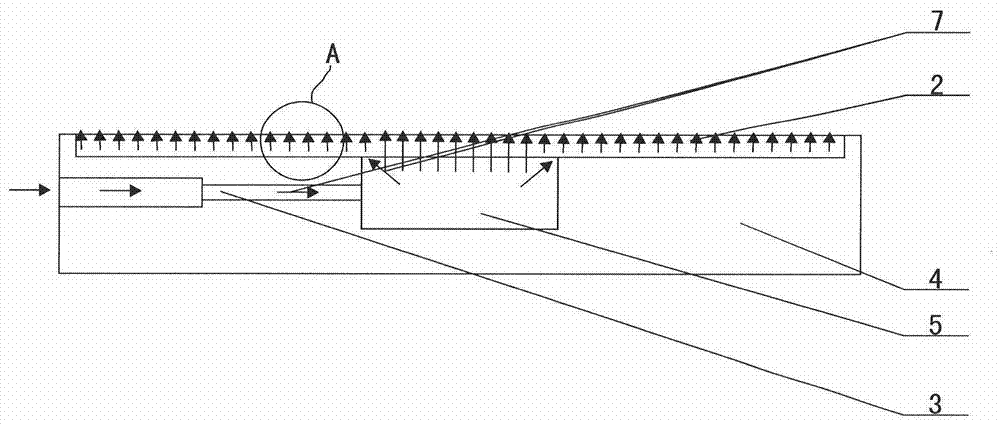

[0019] combined with figure 1 , 2 , 3 or 4, a kind of air-floating guide rail suitable for ultra-precision detection or ultra-high-precision processing equipment, including a base 4, a nano-carbon fiber guide rail 2, and a raised bar type sliding limiter is respectively provided on both sides of the upper surface of the base 4 Position mechanism 1 "The main purpose of the sliding limit mechanism 1 of the present invention is to prevent the movement of the carbon nanofiber guide rail 2 on the base 4, that is to say, as long as the glue that can prevent the carbon nanofiber guide rail 2 from moving is fixed on the base 4 and the base 4 Setting up raised blocks to cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com