Micro-fluidic chip and applications thereof

A microfluidic chip and chip technology, applied in instruments, analyzing materials through chemical reactions, and analyzing materials through observation of the influence of chemical indicators, can solve problems such as identification, and achieve simple sample processing and low cost. Dosage, convenient modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

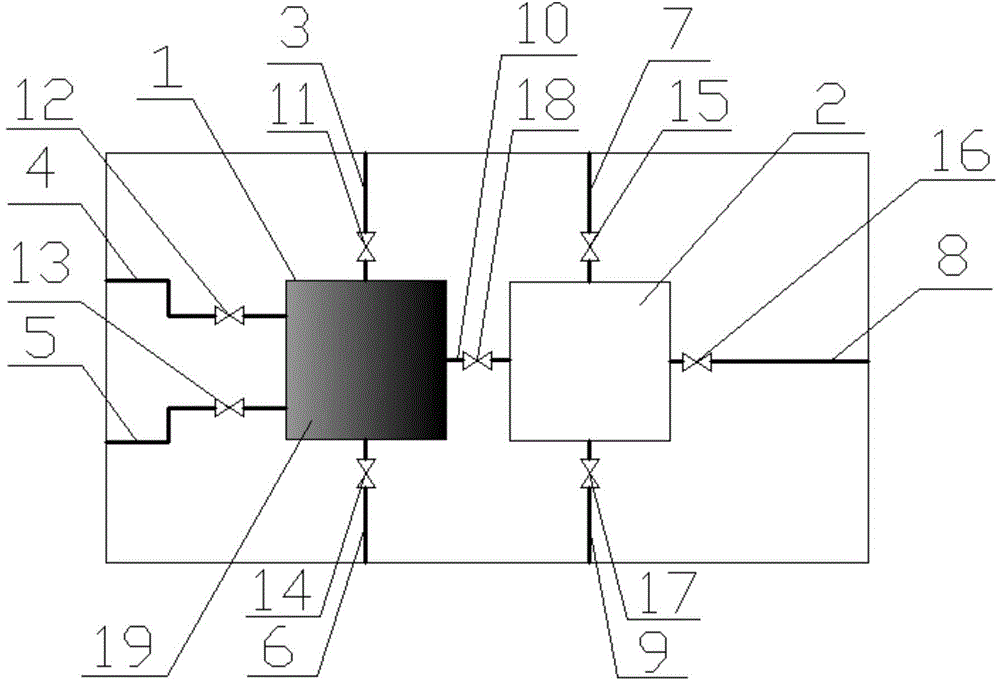

[0038] Step 1, open the first valve (11), close other valves, by the thia graphene / γ-Fe of 200 μ L 2mg / mL 2 o 3 The aqueous dispersion of the nanocomposite material is sent into the first mixing tank (1), the first valve (11) is closed, and the thia graphene / γ-Fe 2 o 3 After the nanocomposite is fixed on the bottom of the first mixing pool (1) by a powerful magnet (19), the fourth valve (14) is opened, the water is discharged through the pump, the fourth valve (14) is closed, and the first mixing pool (1) is dried. );

[0039] Step 2, open the second valve (12), close other valves, send 100 μ L of phosphate buffer solution (10 mM, pH=7.4) containing 0.5 units of lactate oxidase into the first mixing pool (1) through the pump, and close the second mixing pool (1). Valve (12); open the third valve (13), send 100 μL of phosphate buffer solution (10 mM, pH=7.4) containing 10 μmol of lactic acid into the first mixing tank (1) through the pump, and close the third valve (13) , i...

Embodiment 2

[0046] Step 1. Open the second valve (12), send 100 μL of phosphate buffer solution (10 mM, pH=7.4) containing 0.5 units of lactate oxidase into the first mixing pool (1) through the pump, and then close the second valve (12) ; Open the third valve (13), send 100 μL of phosphate buffer solution (10 mM, pH=7.4) containing 10 μmol of lactic acid into the first mixing pool (1) through the pump, close the third valve (13), and incubate the reaction ;

[0047] Step 2, open the eighth valve (18), send the mixed solution after the incubation reaction in step 1 to the second mixing tank (2) through the pump, and close the eighth valve (18);

[0048] Step 3, open the fifth valve (15), send 200 μ L of 0.2M acetic acid buffer solution (pH=4.0) into the second mixing tank (2) through the pump, close the fifth valve (15); open the sixth valve (16) , send 100 μL of an alcohol solution containing 0.5 mg 3,3',5,5'-tetramethylbenzidine into the second mixing pool (2) through a pump, close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com