Nuclear power plant end-of-life reactivity control method

A reactive control, end-of-life technology, applied in nuclear power generation, climate sustainability, greenhouse gas reduction, etc., can solve problems such as deviation of water chemistry working conditions, unreasonable design of boron removal process, increase of alkali metal ions, etc. Huge economic and social benefits, increase utilization rate and economy, reduce the effect of three waste treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

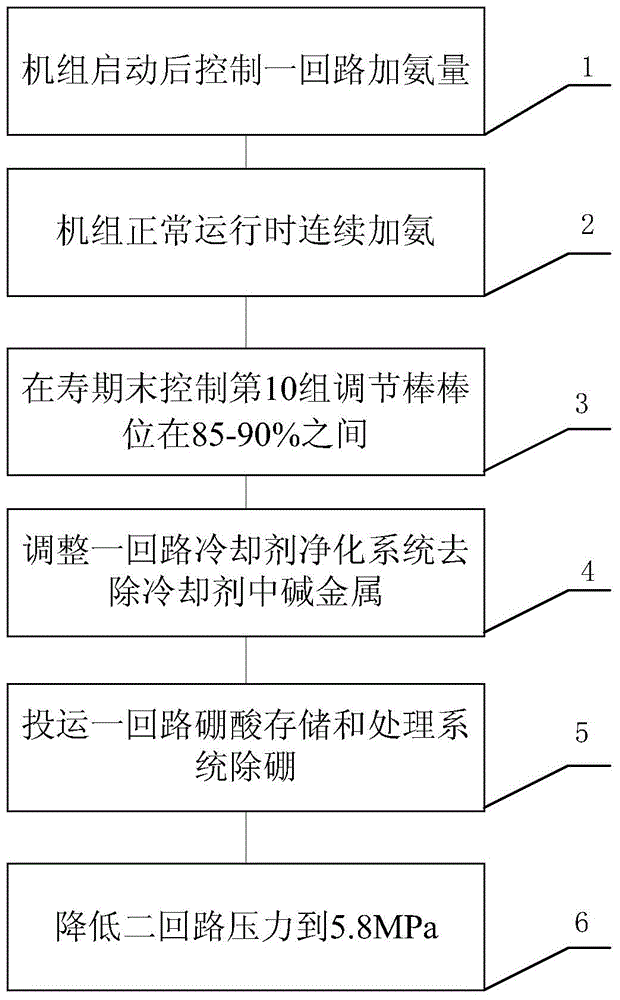

[0019] Such as figure 1 As shown, a kind of nuclear power plant end-of-life reactivity control method provided by the present invention comprises the following steps:

[0020] (1) Add ammonia intermittently after the unit starts

[0021] After the reactor unit is started, when the ammonia concentration in the coolant increases to 20-30mg / L, the ammonia concentration in the primary loop coolant is controlled by reducing the amount of ammonia added, and gradually reaches a dynamic balance with the consumption and input of ammonia. Ensure that the control target of ammonia concentration is 15mg / L. After optimization, the chloride ion concentration in the purification system and coolant is significantly reduced, only 1 / 10 of the original value, and the purification system works stably.

[0022] (2) Continuous ammonia addition during normal opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com